Back sheet for a solar cell module, and solar cell module comprising same

A technology for solar cells and back sheets, applied in applications, circuits, electronic equipment, etc., can solve problems such as weak adhesion, and achieve the effects of improving adhesion, excellent heat dissipation characteristics, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

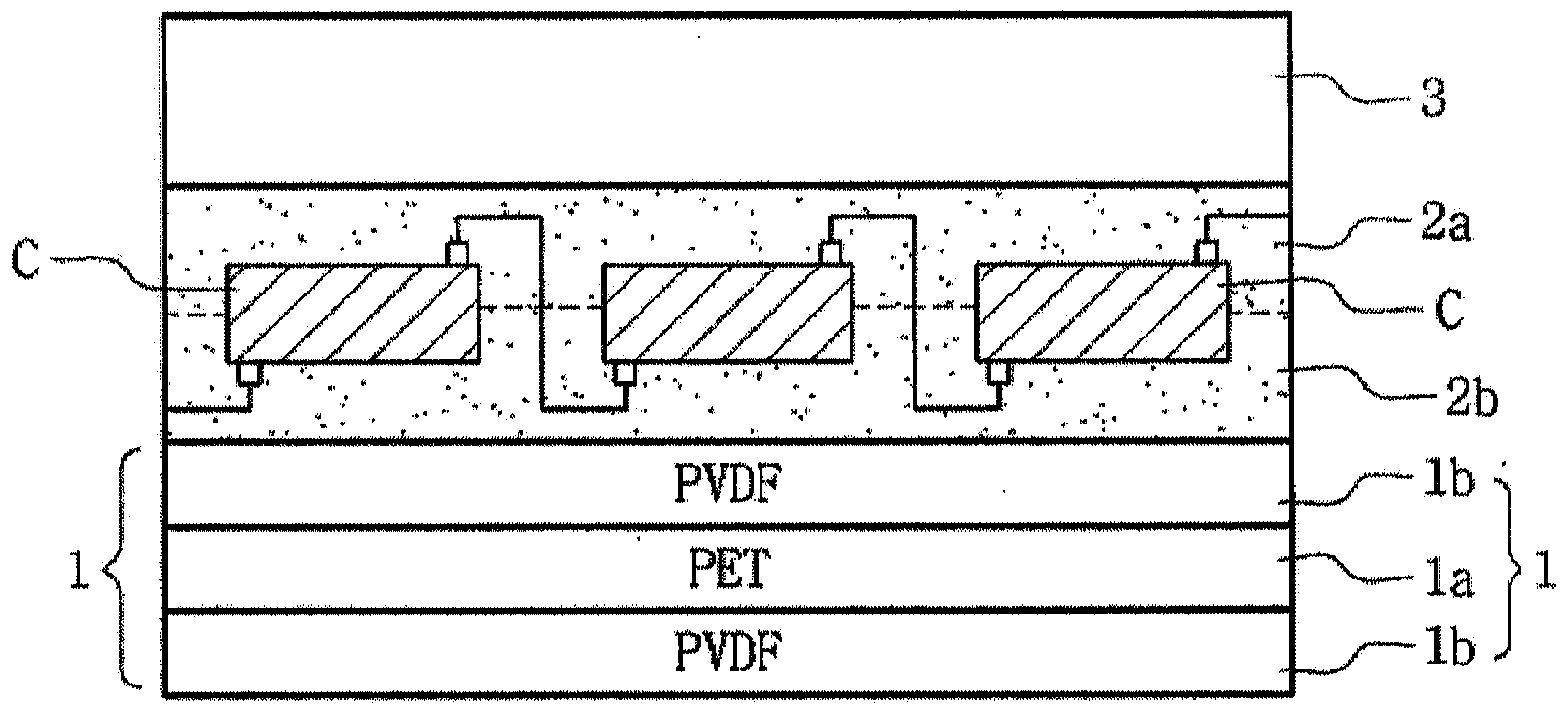

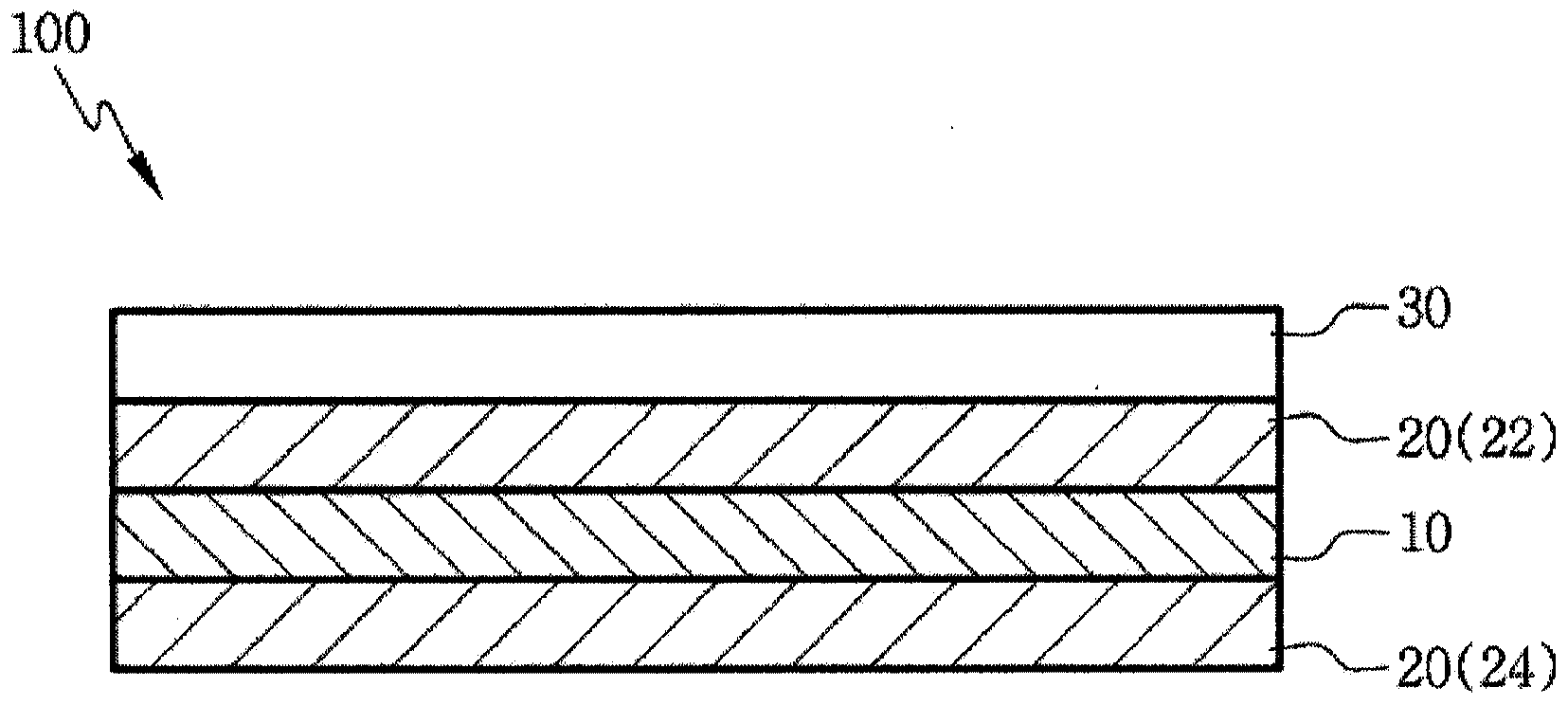

[0114] 10 parts by weight of titanium dioxide (TiO2) with an average particle size of 3 μm 2 ) mixed with 100 parts by weight of polyethylene (PE). The mixture was prepared into a 150 μm thick white PE film (hereinafter, referred to as “W-PE film”) by biaxial stretching.

[0115] After forming an anti-corrosion layer on both surfaces of the 80 μm thick aluminum (Al) film, the above-prepared W-PE film (PE+TiO 2 ) attached on its surface to prepare a backplane with a stacked structure of W-PE film / anti-corrosion layer / Al film / anti-corrosion layer. The anticorrosion layer was formed by treating both surfaces of the aluminum (Al) film with chromic acid to a thickness of about 1 μm.

Embodiment 2

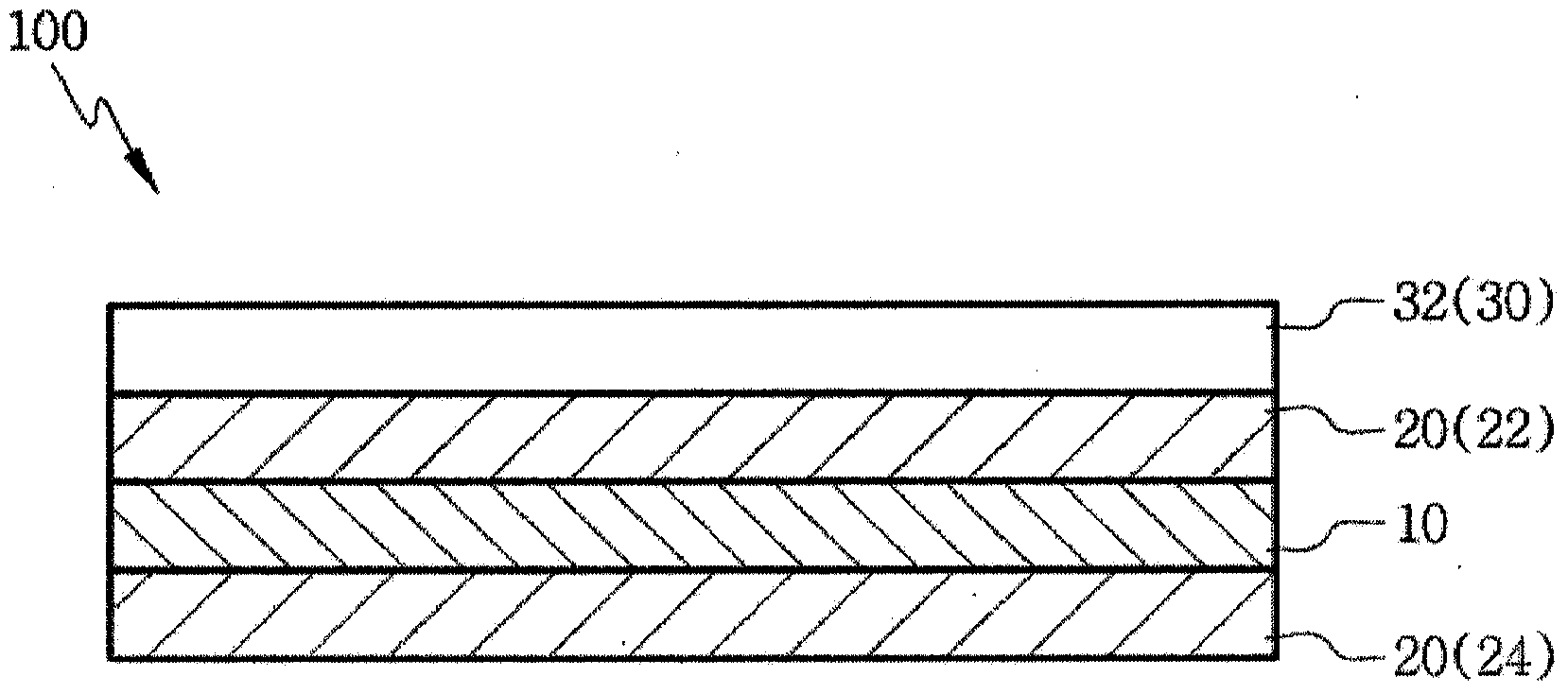

[0117] A back sheet was prepared in the same manner as in Example 1 except that a fluorine coating was also formed.

[0118] Specifically, by using a W-PE-free film (PE+TiO 2 ) on the attached anti-corrosion layer, the fluororesin composition was gravure-coated and hardened to a thickness of 20 μm to prepare a back plate with a stacked structure of W-PE film / anti-corrosion layer / Al film / corrosion-resistant layer / fluorine coating , the fluororesin composition is obtained by mixing PTFE and ethanol at 1:1 (weight ratio).

Embodiment 3

[0120] A back sheet was prepared in the same manner as in Example 1 except that a heat-dissipating ink coating was also formed. Specifically, a W-PE film / anticorrosion layer / Al film was prepared by gravure coating a liquid ink composition comprising acrylic resin and graphite powder in a weight ratio of 1:1 on the anticorrosion layer and hardening to a thickness of 25 μm. / anti-corrosion layer / heat dissipation ink coating stack structure backplane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap