Method for processing resistate generated in film clarification process of fruit-vegetable juice production

A treatment method and clarification treatment technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve problems such as insufficient extraction of fruit and vegetable juices, difficult treatment of retentate, incomplete solid-liquid phase separation, etc. Achieve the effect of realizing clean production, increasing final output and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A treatment method for the retentate produced in the film clarification process of apple juice production:

[0032] (1) Mix the retentate produced during the film clarification process of apple juice production with diatomaceous earth; wherein the content of insoluble solids in the retentate is 36%, and the amount of diatomite added accounts for 0.25% of the total mass of the retentate ;

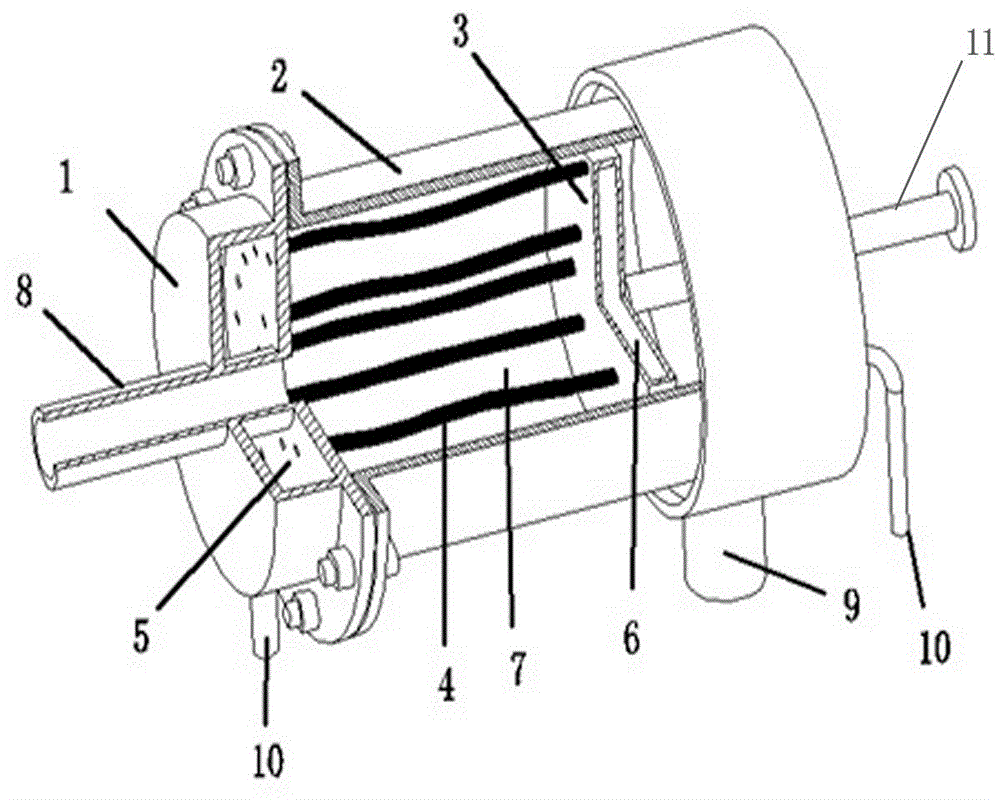

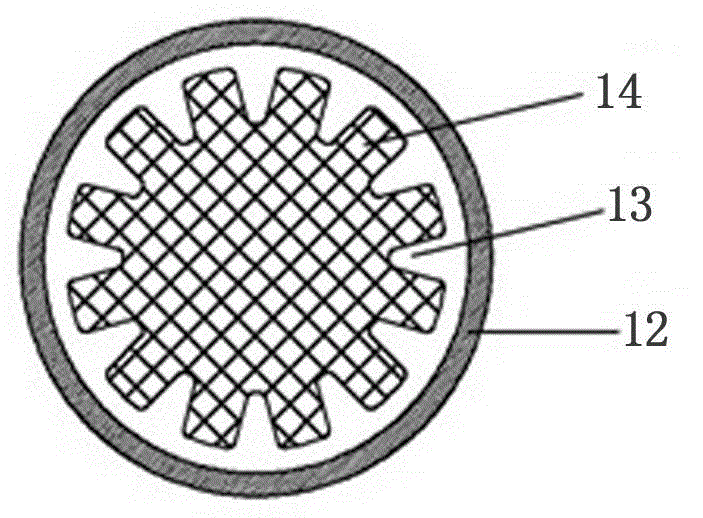

[0033] (2) Inject the mixture of the retentate and diatomaceous earth into a closed external pressure membrane filter press device for pressure filtration treatment, and control the working pressure of the filter press device at 0.45~0.5MPa to obtain liquid-phase clear juice and solid pomace;

[0034] (3) After the pressure filtration, the collected liquid-phase clear juice was directly mixed with the clarified apple juice product, the recovery rate of the residual apple juice in the retentate was 99%, and the light transmittance of the liquid-phase clear juice (T 625nm ) up to 98%, ...

Embodiment 2

[0037] A processing method for the retentate produced in the film clarification process of pineapple juice production:

[0038] (1) The retentate produced in the film clarification process of pineapple juice production is mixed evenly with perlite; wherein the content of insoluble solids in the retentate is 28%, and the addition of perlite accounts for 0.12% of the total mass of the retentate;

[0039] (2) Inject the mixture of retentate and perlite into a closed external pressure membrane filter press device for press filtration treatment, and control the working pressure of the filter press device at 0.45~0.5MPa to obtain liquid-phase clear juice and solid pomace;

[0040] (3) After the pressure filtration is finished, the collected liquid phase clear juice is directly mixed with the pineapple juice product, the recovery rate of pineapple juice remaining in the retentate reaches 99%, and the light transmittance of the liquid phase clear juice (T 625nm ) up to 96%, turbidity ...

Embodiment 3

[0043] A kind of processing method of the retentate produced in the film clarification process of jujube juice production:

[0044] (1) Mix the retentate produced in the film clarification process of jujube juice with activated carbon evenly; wherein the content of insoluble solids in the retentate is 42%, and the addition of activated carbon accounts for 0.36% of the total mass of the retentate;

[0045] (2) Inject the mixture of retentate and activated carbon into a closed external pressure membrane filter press device for pressure filtration treatment, and control the working pressure of the filter press device at 0.5~0.55MPa to obtain liquid-phase clear juice and solid pomace;

[0046] (3) After the pressure filtration, the collected liquid-phase clear juice was directly mixed with the jujube juice product, the recovery rate of the jujube juice remaining in the retentate was 99%, and the light transmittance of the liquid-phase clear juice (T 625nm ) up to 95%, turbidity <3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com