Preparation method of activated carbon fiber net of air purifier

A technology of activated carbon filter screen and air purifier, which is applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve the problems of affecting the adsorption and filtration function of activated carbon, blocking the micropore structure of activated carbon, and the difficulty of evenly filling activated carbon, etc., to achieve High adsorption and filtration efficiency, easy operation, and flexible processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Sieve 10 mesh granular coconut shell activated carbon;

[0018] (2) Use 0.5 mm thick 10-mesh PP stretched net roll material as the polymer support net, evenly spray molten EVA adhesive fibers with thermoplasticity and a melting point of 85°C on the surface of the polymer support net, and then distribute them evenly through activated carbon The device evenly sprays 10 purpose granular coconut shell activated carbons in step 1, and the thickness is 1 millimeter;

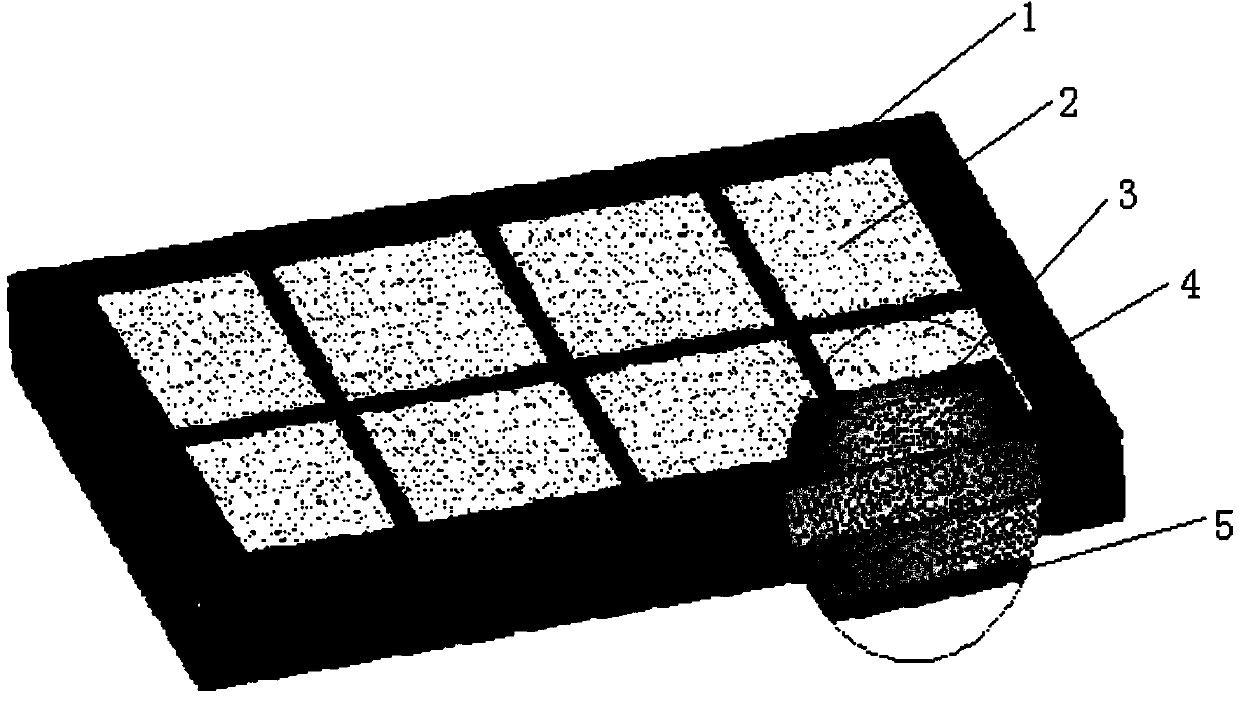

[0019] (3) Press the polymer support net after step 2 with a soft heat conduction roller. After the thermoplastic EVA adhesive fiber is cooled and solidified, the 10-mesh granular coconut shell activated carbon can be adhered to the surface of the polymer support net to obtain an activated carbon filter. Layer 4;

[0020] (4) By continuously repeating steps 1-3, the rolled activated carbon filter layer 4 is cut into sheets of 290*449 mm, and 3 pieces are stacked to obtain an air purifier activated carbon fi...

Embodiment 2

[0023] (1) Sieve 20-mesh granular asphalt-based activated carbon loaded with nano-silver antibacterial and antibacterial functional components; sieve 20-mesh granular coconut shell activated carbon, and mix the above two activated carbons in a mass ratio of 3:7 to form an activated carbon mixture particles;

[0024] (2) Use 0.5 mm thick 30-mesh PA stretched net roll material as the polymer support net, evenly spray molten EVA adhesive fibers with thermoplasticity and a melting point of 95°C on the surface of the polymer support net, and then distribute them evenly through activated carbon Spray evenly the 20 purpose activated carbon mixed particles in step 1, the thickness is 1.5 millimeters;

[0025] (3) Press the polymer support net after step 2 with a soft heat-conducting roller, and after the thermoplastic EVA binder fiber is cooled and solidified, the 20-mesh activated carbon mixed particles in step 1 can be adhered to the surface of the polymer support net to obtain Act...

Embodiment 3

[0029] (1) Sieve 30-mesh granular coconut shell activated carbon loaded with nano-silver antibacterial and antibacterial functional components; sieve 30-mesh granular coal-based activated carbon loaded with odor-decomposing functional components (activated nano-alumina); Untreated granular coconut shell activated carbon; the above three activated carbons are mixed uniformly in a mass ratio of 1:1:3 to form activated carbon mixed particles;

[0030] (2) Use 0.5 mm thick 30-mesh PET stretched net roll material as the polymer support net, evenly spray molten EVA adhesive fibers with thermoplasticity and a melting point of 105°C on the surface of the polymer support net, and then distribute them evenly through activated carbon Spray evenly the 30 mesh active carbon mixed particles in step 1, the thickness is 2 millimeters;

[0031] (3) Press the polymer support net after step 2 with a soft heat conduction roller, and after the thermoplastic EVA binder fiber is cooled and solidifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com