Automatic lithium battery picker

A technology of sorting machine and lithium battery, applied in the field of lithium battery automatic sorting machine, can solve the problems of insecurity, low work efficiency, inconvenient operation, etc., and achieve the effect of high openness, convenient maintenance, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further illustrate the present invention below in conjunction with accompanying drawing

[0021] Referring to the attached picture:

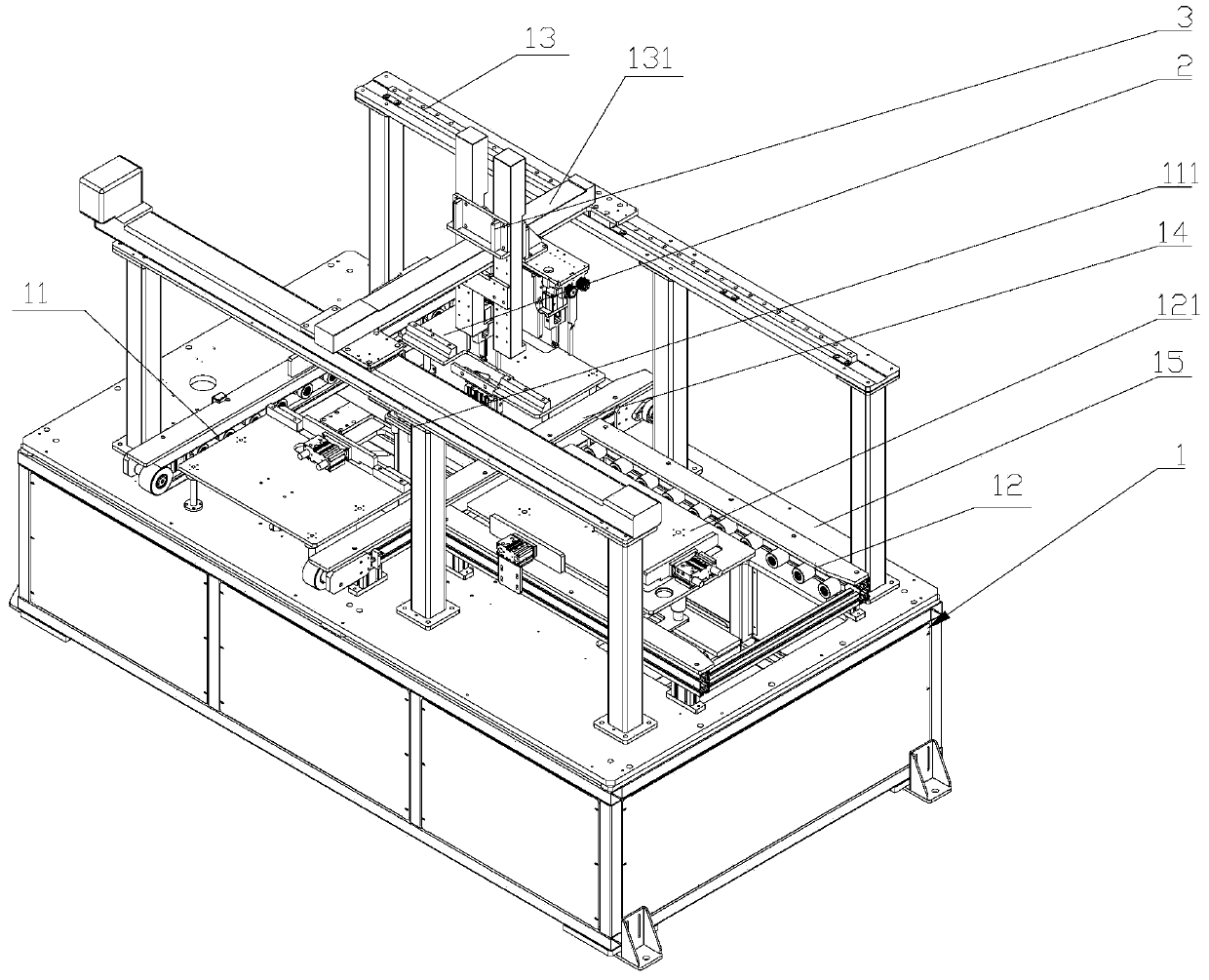

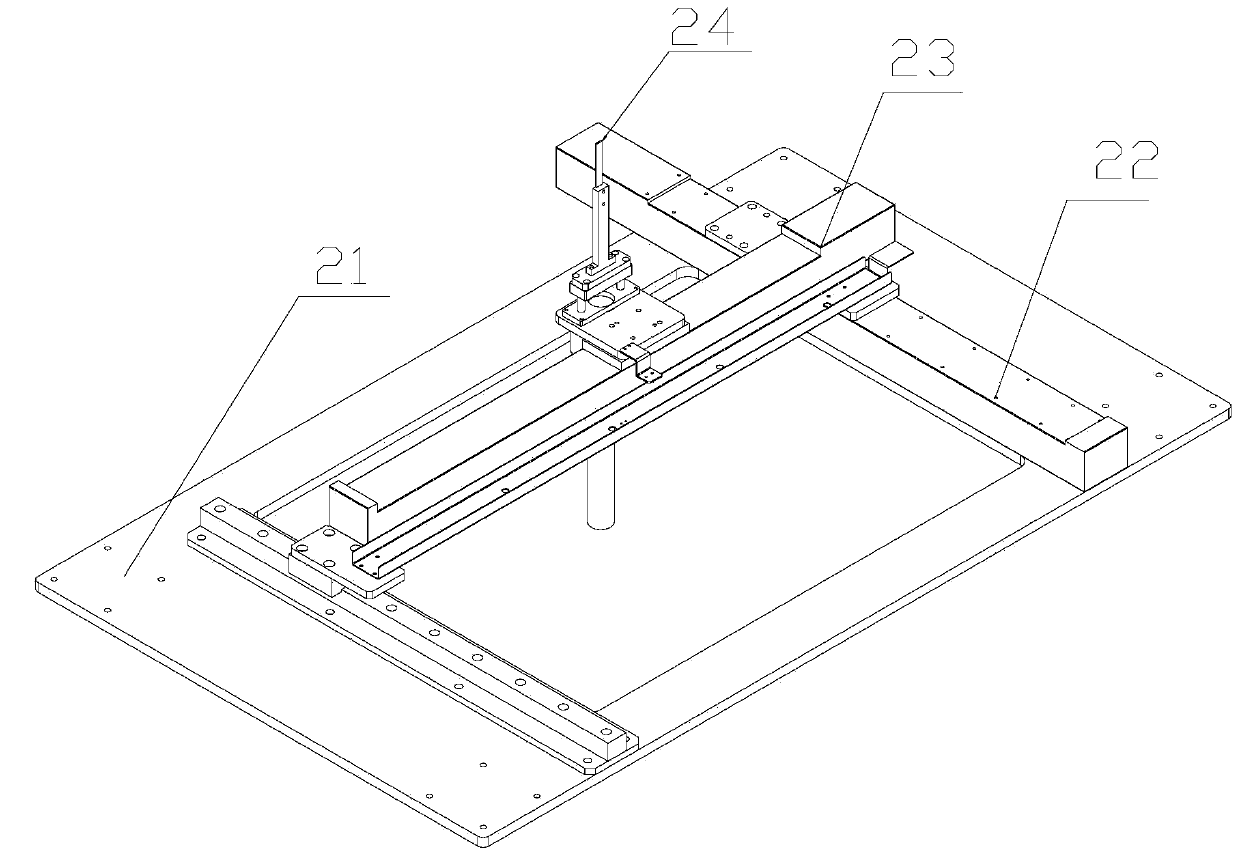

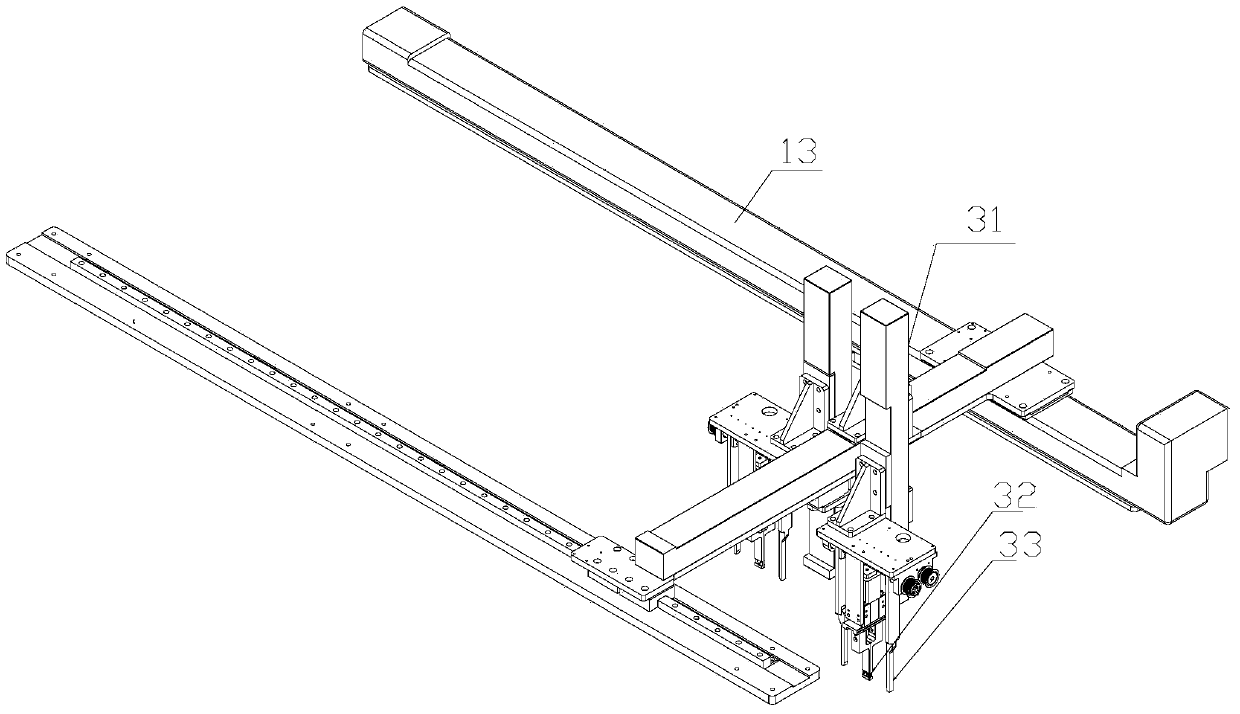

[0022] The lithium battery automatic picking machine of the present invention includes a base 1, a jacking device 2, a picking device 3, a controller, and a computer. The auxiliary conveyor belt 12 of the station 15, the double guide rail 13 erected above the main conveyor belt and the auxiliary conveyor belt; the picking station and the NG battery station are respectively equipped with a picking station fixing frame 111 and a NG battery station tray fixed frame 121; the described picking device 3 is erected between the double guide rails 13 through the slide bar 131; the described jacking device 2 is installed at the picking station of the main conveyor belt 11; the described computer is provided with a pallet database, the The computer described above communicates bidirectionally with the controller; the controller is equipped with a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com