A dual-melting-pole arc welding torch based on heat input control and its welding method

A double melting electrode and arc welding technology, which is applied in the direction of arc welding equipment, welding equipment, welding accessories, etc., to achieve the effect of reducing welding spatter, reducing welding costs, and good arc rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

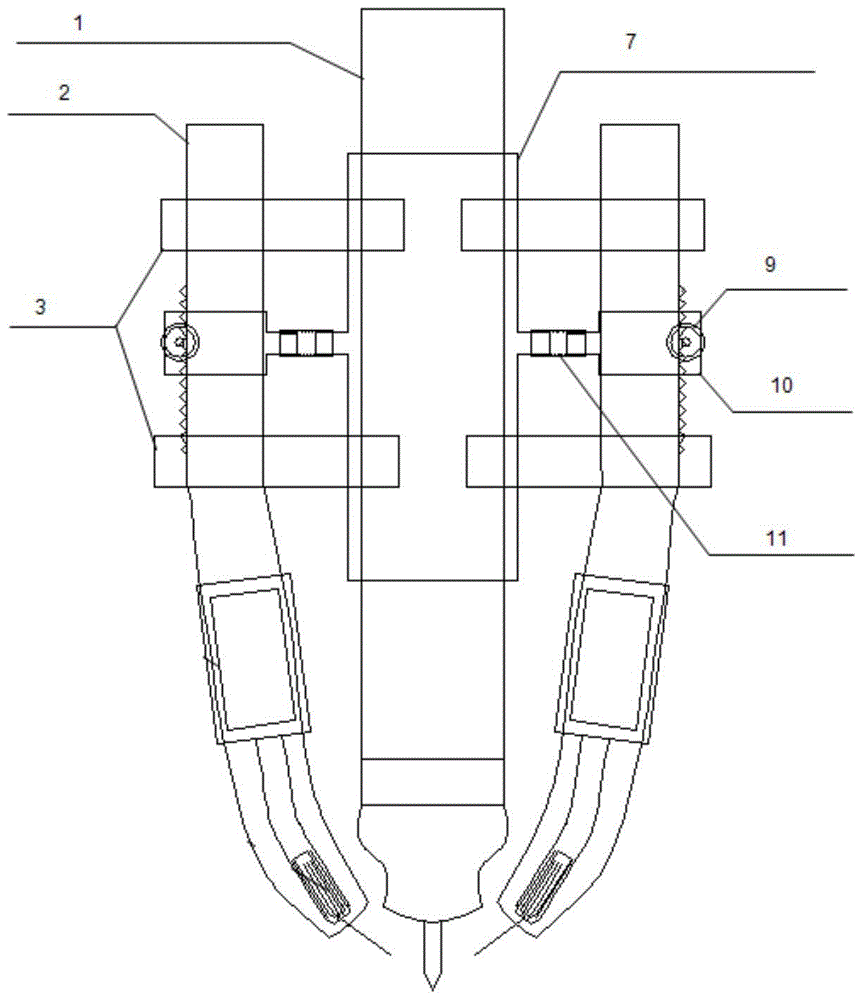

[0026] The present invention is described in more detail below in conjunction with accompanying drawing:

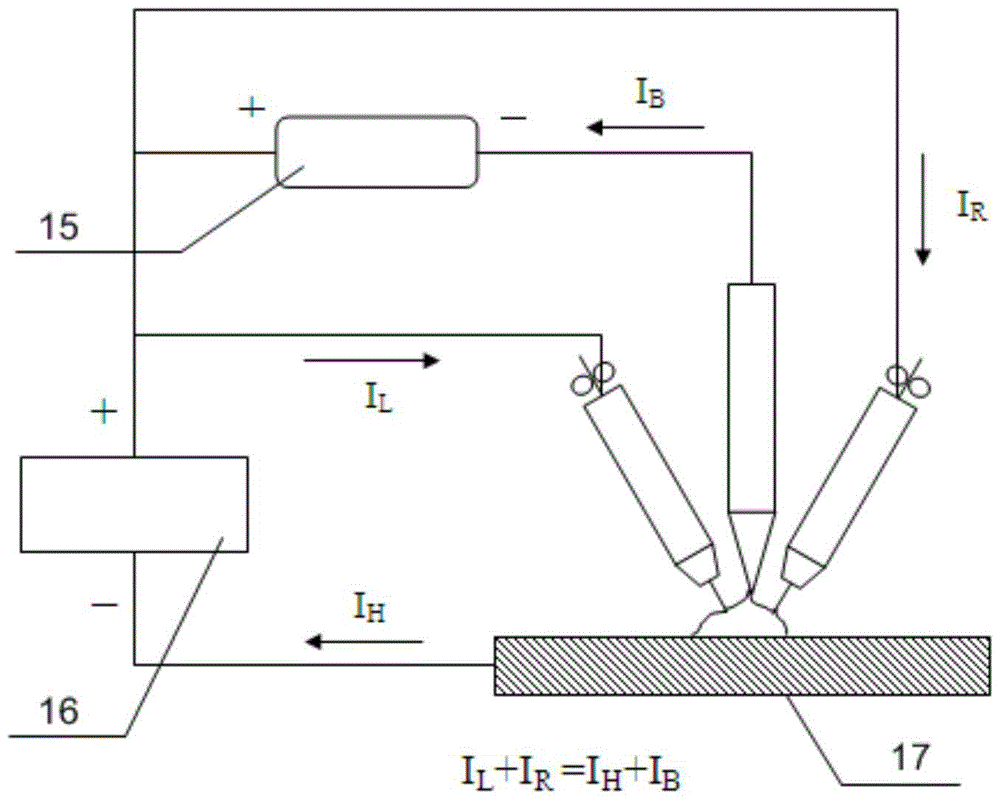

[0027] The present invention relates to a dual melting electrode arc welding torch based on heat input control and its welding method. In order to achieve the purpose, the present invention adopts the following technical solutions:

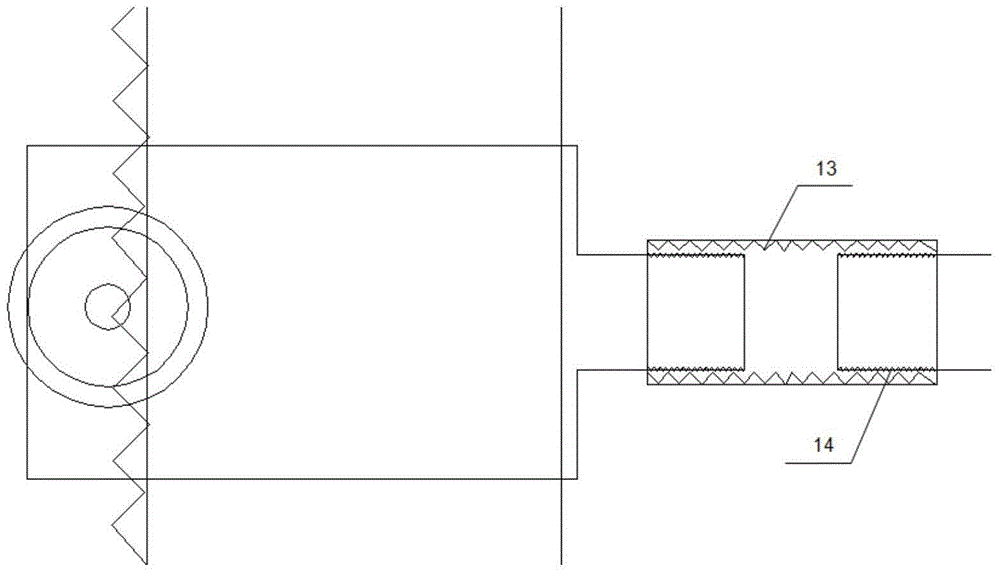

[0028] The welding torch is composed of two MIG arc welding torches (MIG welding torch I, MIG welding torch II) and one non-melting electrode gas shielding arc welding torch (TIG welding torch) and related mechanical adjustment structures. Fix the auxiliary jacket on the TIG welding torch and connect it with the MIG welding torch on both sides through the connecting sleeve. The screw rods between the MIG welding torch and the TIG welding torch on both sides are connected through an auxiliary sleeve with an internal thread. When the sleeve rotates in one direction, the two screw rods approach each other at the same time, and vice versa, and mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com