High transmittance nano-porous aerogel material and preparation method thereof

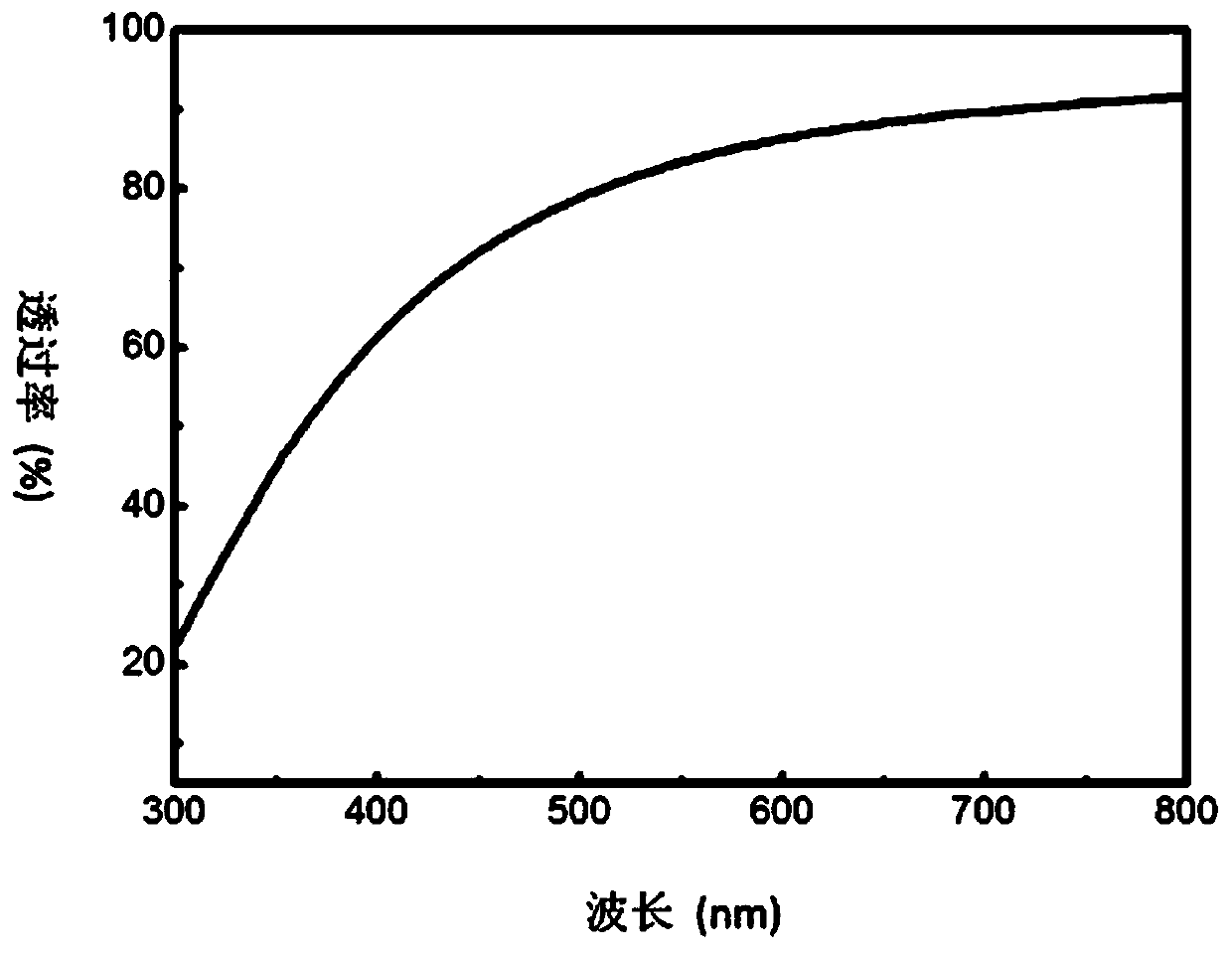

A high-transmittance, nano-porous technology, applied in the direction of silica, bulk chemical production, silicon oxide, etc., can solve the influence of physical properties and microstructure by heat treatment process, which has not been reported in the literature and scientific research problems have not been It can completely solve problems such as holes and achieve the effect of avoiding hole collapse and network structure damage, strong hardness and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The first step is to use methyl silicate, methanol, insufficient water and appropriate amount of hydrochloric acid according to the molar ratio of 1: 2.4: 1.5: 10 -5 mix. The mixed solution was refluxed at 85°C for 20 hours to achieve full mixing and increase the hydrolysis rate, and then distilled at 95°C for 4 hours to remove the methanol generated by the reaction to obtain partially hydrolyzed and partially polycondensed silica sol (CS), colloidal particles smaller in size;

[0028] The second step reaction is to mix CS with acetonitrile, water and ammonia water in a volume ratio of 1:50:2.5:0.06. SiO is obtained after full hydrolysis 2 Sol, and then pour the sol into the mold, after about 20 minutes, the polycondensation reaction forms a uniform and transparent SiO 2 gel. The wet gel was covered with a small amount of acetonitrile and aged for 1 day, and then replaced with acetonitrile three times, each time for 12 hours.

[0029] SiO 2 Put the wet gel into th...

Embodiment 2

[0032] The first step is to use methyl silicate, methanol, insufficient water and appropriate amount of hydrochloric acid according to the molar ratio of 1: 2.2: 1.3: 10 -5 mix. The mixed solution was refluxed at 85°C for 20 hours to achieve full mixing and increase the hydrolysis rate, and then distilled at 95°C for 4 hours to remove the methanol generated by the reaction to obtain partially hydrolyzed and partially polycondensed silica sol (CS), colloidal particles smaller in size;

[0033] The second step reaction is to mix CS with acetonitrile, water and ammonia water in a volume ratio of 1:40:2.5:0.05. SiO is obtained after full hydrolysis 2 Sol, and then pour the sol into the mold, after about 20 minutes, the polycondensation reaction forms a uniform and transparent SiO 2 gel. The wet gel was covered with a small amount of acetonitrile and aged for 1 day, and then replaced with acetonitrile three times, each time for 12 hours.

[0034] SiO 2 Put the wet gel into th...

Embodiment 3

[0037]In the first step, the molar ratio of methyl silicate, methanol, insufficient water and appropriate amount of hydrochloric acid is 1: 2.8: 1.4: 4×10 -5 mix. The mixed solution was refluxed at 85°C for 20 hours to achieve full mixing and increase the hydrolysis rate, and then distilled at 95°C for 4 hours to remove the methanol generated by the reaction to obtain partially hydrolyzed and partially polycondensed silica sol (CS), colloidal particles smaller in size;

[0038] The second step reaction is to mix CS with acetonitrile, water and ammonia water in a volume ratio of 1:35:2.5:0.045. SiO is obtained after full hydrolysis 2 Sol, and then pour the sol into the mold, after about 20 minutes, the polycondensation reaction forms a uniform and transparent SiO 2 gel. The wet gel was covered with a small amount of acetonitrile and aged for 1 day, and then replaced with acetonitrile three times, each time for 12 hours.

[0039] SiO 2 Put the wet gel into the supercritica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

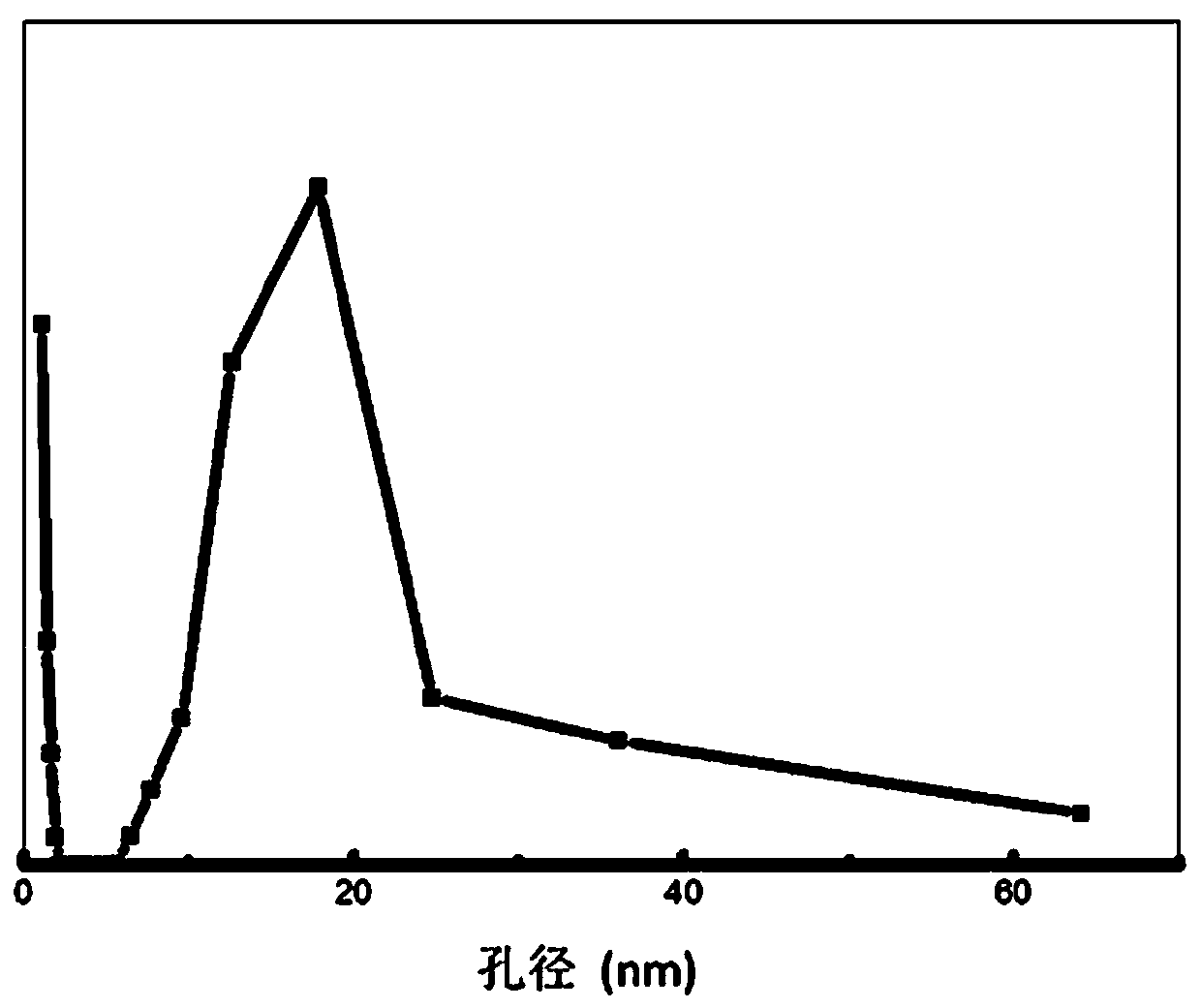

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com