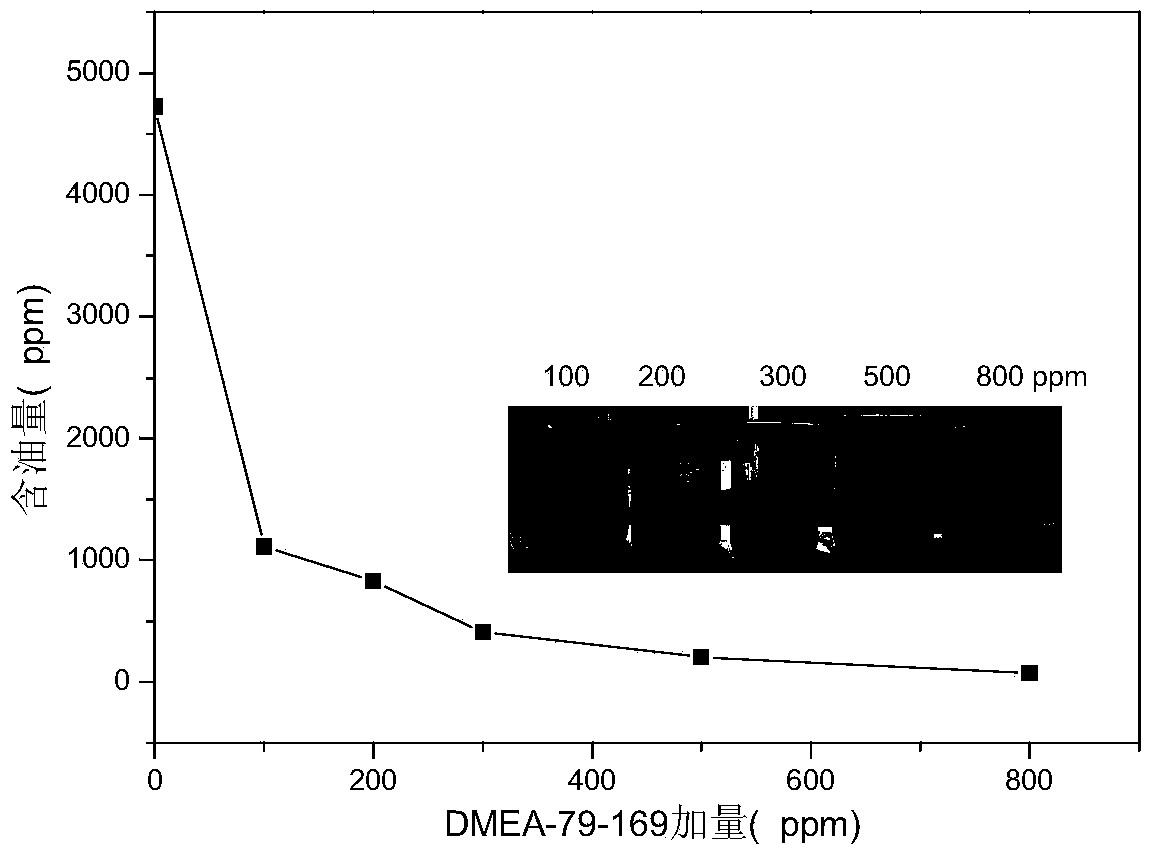

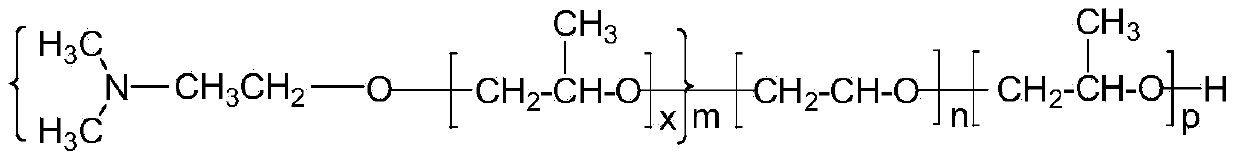

Block polyether oilfield sewage treatment agent taking N'N-dimethyl ethanolamine as initiator and preparation method thereof

A technology of dimethylethanolamine and oilfield sewage, which is applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of affecting the normal production of oilfields, affecting the efficiency of sewage treatment, and increasing the production cost of oilfields. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1N'N-dimethylethanolamine is the preparation of the polypropylene oxide oil head of initiator

[0027] Add 10g of N'N-dimethylethanolamine and 2.4g of potassium hydroxide to the high-temperature and high-pressure reactor, and seal the reactor. Before heating up, use nitrogen to blow and replace, then use a vacuum pump to evacuate, repeat twice, then start stirring and raise the temperature, stop heating when the temperature rises to 120°C, open the feed valve, add 790g of propylene oxide dropwise, and control the reaction The temperature does not exceed 140°C and the pressure is controlled below 0.4MPa. After the reaction of the materials is completed, the pressure drops and then reacts for 30 minutes to reduce the pressure to 0MPa. Finally, cool down and open the kettle to obtain N'N-dimethylethanolamine as the initiator Polypropylene oxide oil head, marked as DMEA-79.

Embodiment 2

[0028] Embodiment 2N'N-dimethylethanolamine is that initiator is the preparation of the polypropylene oxide oil head of initiator

[0029] Add 10g of N'N-dimethylethanolamine as a starter and 1.16g of potassium hydroxide to a high-temperature and high-pressure reactor, and seal the reactor. Before heating up, use nitrogen to blow and replace, then use a vacuum pump to evacuate, repeat twice, then start stirring and raise the temperature, stop heating when the temperature rises to 120°C, open the feed valve, add 570g of propylene oxide dropwise, and control the reaction The temperature does not exceed 140°C and the pressure is controlled below 0.4MPa. After the reaction of the materials is completed, the pressure drops and then reacts for 30 minutes to reduce the pressure to 0MPa. Finally, cool down and open the kettle to obtain N'N-dimethylethanolamine as the initiator Polypropylene oxide oil head as starter, marked as DMEA-57.

Embodiment 3

[0031] The method of Example 1 is adopted, but the amount of propylene oxide is changed to 340g, 450g, and 990g respectively, and the obtained polypropylene oxide oil heads with N'N-dimethylethanolamine as the initiator are respectively marked as DMEA- 34. DMEA-45, DMEA-99.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com