Self-cleaning nano-coating protective film and preparation method thereof

A nano-coating and self-cleaning technology, which is applied in the direction of coatings, film/sheet adhesives, adhesives, etc., can solve the problems of static electricity accumulation, insufficient adhesion, and poor anti-pollution performance of the protective film, and achieve production Low cost, good anti-sand and dust, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

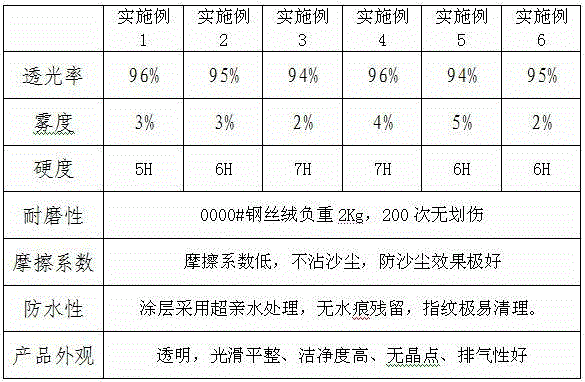

Examples

Embodiment 1

[0046] A method for preparing a self-cleaning nano-coating protective film includes the following processing steps:

[0047] The first step is to prepare nano coatings with self-cleaning function;

[0048] The second step is to use a micro-concave anilox roller to coat the above-mentioned nano-coating on the PET substrate. The number of lines of the micro-concave anilox roller is 140 LPI and the coating volume is 90 square meters / L; The angle is 30 degrees; the coating line speed of the micro-concave anilox roll is 10m / min;

[0049] The third step is to adopt the thermal curing method of oven heating, the heating temperature is 50 ℃, and the heating time is 3 minutes, so that a layer of nano film is formed on the PET substrate;

[0050] The fourth step is to coat the adhesive on the other surface of the PET substrate, heat and cure in an oven, the baking temperature of the oven is 130 ℃, the baking time is 3 minutes, and then the PET peeling layer is pasted on the adhesive layer . T...

Embodiment 2

[0062] A method for preparing a self-cleaning nano-coating protective film includes the following processing steps:

[0063] The first step is to prepare nano coatings with self-cleaning function;

[0064] The second step is to use a micro-concave anilox roll to coat the above-mentioned nano-coating on the PET substrate. The number of lines of the micro-concave anilox roll is 200 LPI, and the coating volume is 100 square meters / L; The angle is 30 degrees; the coating line speed of the micro-concave anilox roll is 10m / min;

[0065] The third step is to adopt the thermal curing method of oven heating, the heating temperature is 55℃, and the heating time is 2.5min, so that a layer of nano film is formed on the PET substrate;

[0066] The fourth step is to coat the adhesive on the other surface of the PET substrate, heat and cure it in an oven, the baking temperature of the oven is 150℃, and the baking time is 2.5min, then the PET peeling layer is pasted on the adhesive layer on. The ad...

Embodiment 3

[0078] A method for preparing a self-cleaning nano-coating protective film includes the following processing steps:

[0079] The first step is to prepare nano coatings with self-cleaning function;

[0080] The second step is to use a micro-concave anilox roller to coat the above-mentioned nano coating on the PET substrate. The number of lines of the micro-concave anilox roller is 350LPI, and the coating volume is 110㎡ / L; The angle is 30 degrees; the coating line speed of the micro-concave anilox roll is 15m / min;

[0081] The third step is to adopt the thermal curing method of oven heating, the heating temperature is 60 ℃, and the heating time is 2 min, so that a layer of nano film is formed on the PET substrate;

[0082] The fourth step is to coat the adhesive on the other surface of the PET substrate, heat and cure in an oven, the baking temperature of the oven is 160℃, and the baking time is 2min, and then stick the PET peeling layer on the adhesive layer . The adhesive is a silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com