Expansion oil well cement with temperature resistance

An oil well cement and performance technology, applied in the field of expanded oil well cement, can solve problems such as inability to solve various complex conditions, inability to meet cementing requirements, etc., achieve good salt resistance and compatibility, improve expansion ratio and elastic modulus, The effect of reducing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The cement slurry system formula used in the experiment is as follows:

[0030] 500g Jiajiang G-grade oil well cement+317mL water+150g silica powder+25g microsilica powder+10g polyurethane elastomer+5gHPAM+3.0g GH-9 high temperature retarder+4g TW-200L high temperature fluid loss additive.

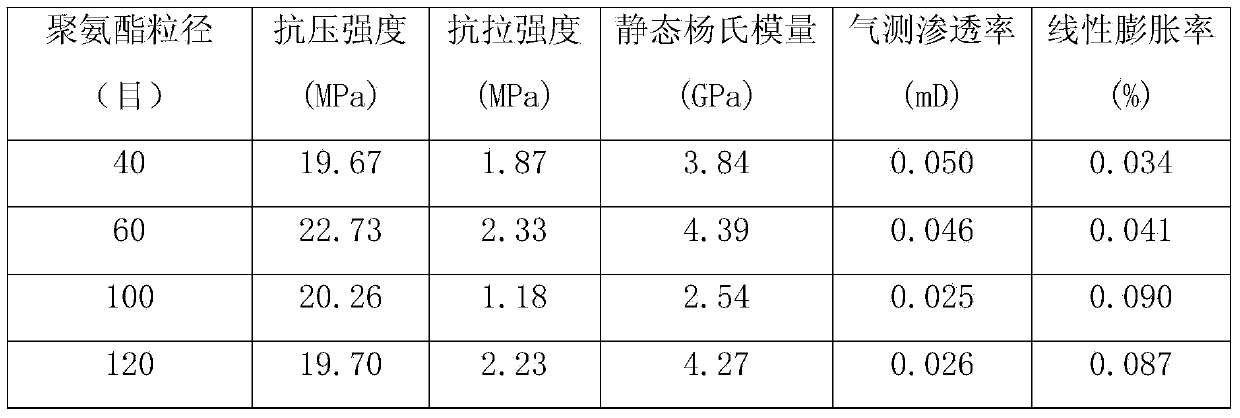

[0031] The test was carried out according to the particle size of the polyurethane elastomer, and the results are shown in Table 1.

[0032] Table 1 The influence of different polyurethane elastomer particle size on the mechanical properties of cement stone

[0033]

[0034]

Embodiment 2

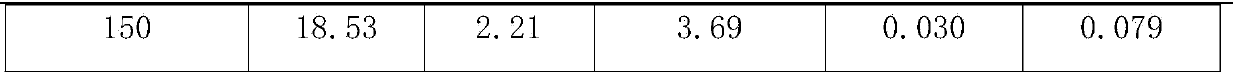

[0036] The cement slurry system formula used in the experiment is as follows:

[0037] Formula 1: 500g Jiajiang G-grade oil well cement+317mL water+150g silica powder+25g micro-silica powder+5g polyurethane elastomer (60 mesh)+5gHPAM+3.0g GH-9 high temperature retarder+4g TW-200L high temperature drop Water loss agent.

[0038] Formula 2: 500g Jiajiang G-grade oil well cement+317mL water+150g silica powder+25g micro-silica powder+10g polyurethane elastomer (60 mesh)+5gHPAM+3.0g GH-9 high temperature retarder+4gTW-200L high temperature loss reduction Water agent.

[0039] Formula 3: 500g Jiajiang G-grade oil well cement+317mL water+150g silica powder+25g micro-silica powder+15g polyurethane elastomer (60 mesh)+5gHPAM+3.0g GH-9 high temperature retarder+4gTW-200L high temperature loss reduction Water agent.

[0040] Among them, the high temperature retarder GH-9 is produced in Tianjin Boxing; the high temperature fluid loss reducer TW-200L is produced in Henan Weihui. HPAM is an anio...

Embodiment 3

[0048] The effect of high temperature retarder on the consistency of cement slurry. The cement slurry system formula used in the experiment is as follows:

[0049] Formula 1: 500g Jiajiang G-grade oil well cement+317mL water+150g silica powder+25g micro silica powder+10g polyurethane elastomer (60 mesh)+5gHPAM+4g TW-200L high temperature fluid loss additive.

[0050] Formula 2: 500g Jiajiang G-grade oil well cement+317mL water+150g silica powder+25g micro-silica powder+10g polyurethane elastomer (60 mesh)+5gHPAM+1.0g GH-9 high temperature retarder+4gTW-200L high temperature loss reduction Water agent.

[0051] Formula 3: 500g Jiajiang G-grade oil well cement+317mL water+150g silica powder+25g micro silica powder+10g polyurethane elastomer (60 mesh)+5gHPAM+2.0g GH-9 high temperature retarder+4gTW-200L high temperature loss reduction Water agent.

[0052] Formula 4: 500g Jiajiang G-grade oil well cement+317mL water+150g silica powder+25g micro silica powder+10g polyurethane elastomer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com