Underground gasification gas injection device and method

An underground gasification and gas injection technology, which is applied in coal gasification, underground mining, construction, etc., can solve the problems of affecting the efficiency of underground coal gasification and stable production process control, and low efficiency, so as to ensure stability, improve quality, reduce The effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention are described below with reference to the drawings.

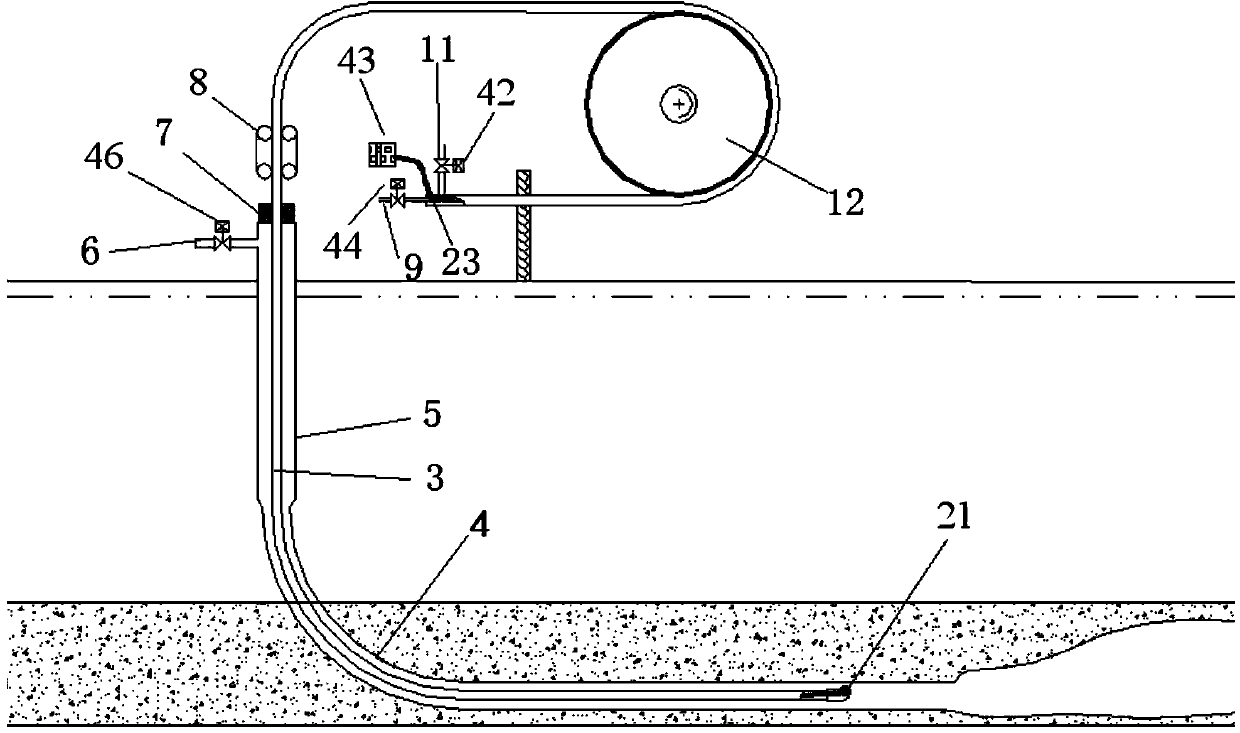

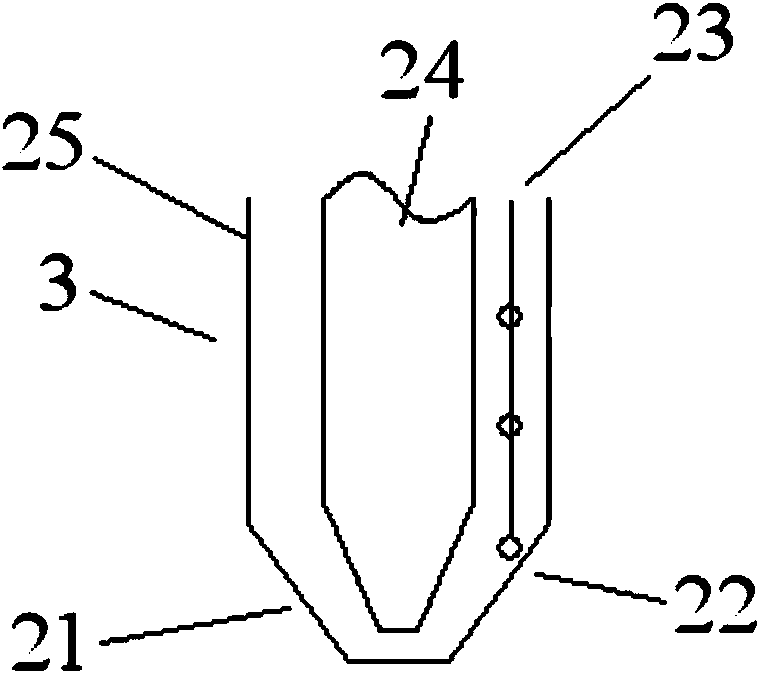

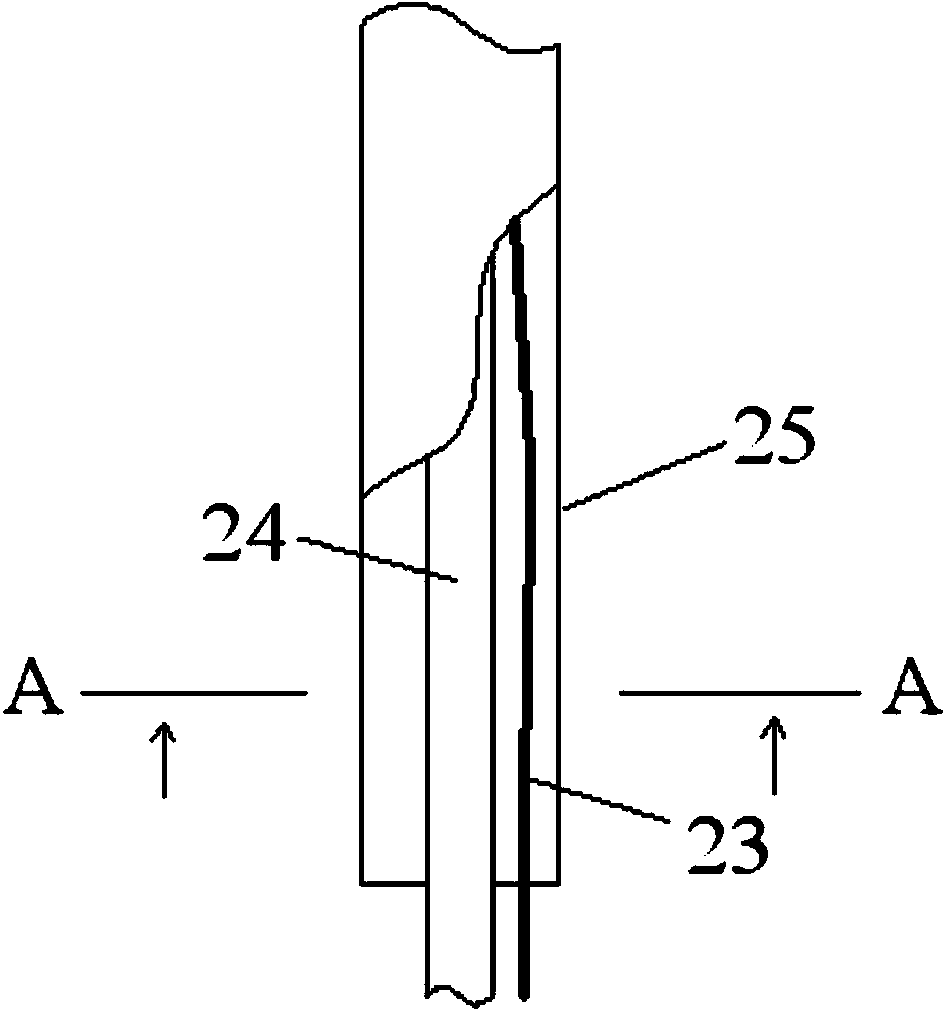

[0032] Such as figure 1 and figure 2 As shown, the underground gasification gas injection device of the present invention includes a gas injection pipe 3 and an atomizing nozzle 21 arranged at one end of the gas injection pipe 3 . Wherein, the gas injection pipe 3 has an outer pipe 25 and an inner pipe 24, the inner pipe 24 is arranged in the outer pipe 25 and is spaced from the outer pipe 25, in other words, two passages that can lead to reactants are formed in the gas injection pipe 3 : the first channel formed by the inner tube 24, and the second channel formed by the space between the outer wall of the inner tube 24 and the inner wall of the outer tube 25.

[0033] refer to figure 2 As shown, the atomizing nozzle 21 has an inner layer nozzle and an outer layer nozzle, wherein the inner layer nozzle communicates with the inner pipe 24 of the gas injection pipe 3 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com