Anti-explosion magnetic liquid filter

A filtrate and magnetic technology, which is applied in the direction of machines/engines, liquid fuel engines, and components of pumping devices for elastic fluids, etc., can solve problems such as environmental hazards to personnel and equipment, threats to mechanical seal end faces, and medium leakage in pumps. Achieve the effects of convenient processing and manufacturing, reliable long-term operation, and preventing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

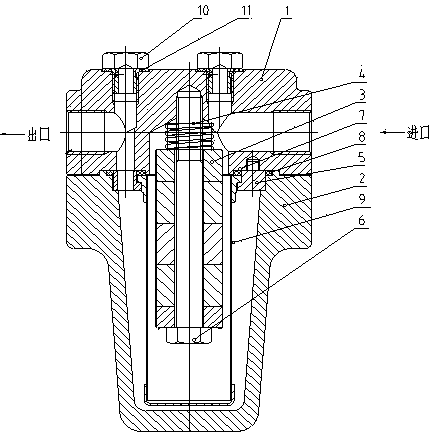

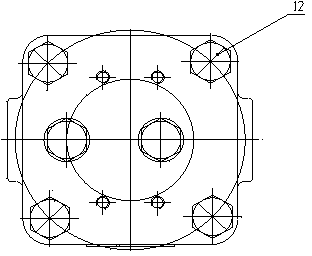

[0012] The present invention is further described below in conjunction with accompanying drawing:

[0013] As shown in the drawings, an explosion-proof magnetic liquid filter is provided with a mechanical seal flushing pipeline, and is characterized in that it is provided with a filter housing 2, a filter cover 1, a magnetic core assembly 3 and a filter screen assembly 9, and the magnetic core assembly 3 includes bolts 6, springs 4 and magnetic core 3. The filter screen assembly 9 includes filter screens, sealing rings 5 and sealing rings 7, 8. The center of the filter housing 2 is provided with a filter cavity, and the end of the filter housing 2 After the filter cover 1 is sealed and connected, the center of one end face of the filter cover 1 is provided with a liquid inlet hole and a threaded blind hole in turn, one side is provided with a liquid inlet port, and the other side is provided with a liquid outlet port, and one side of the liquid inlet hole is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com