Tube orifice diameter variable spliced sampling instrument

A plug-in, sampler technology, applied in sampling devices and other directions, can solve the problems of wasteful treatment cost, time-consuming, and inability to connect, and achieve the effect of reducing pressure gradient, avoiding artificial pollution, and reducing contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

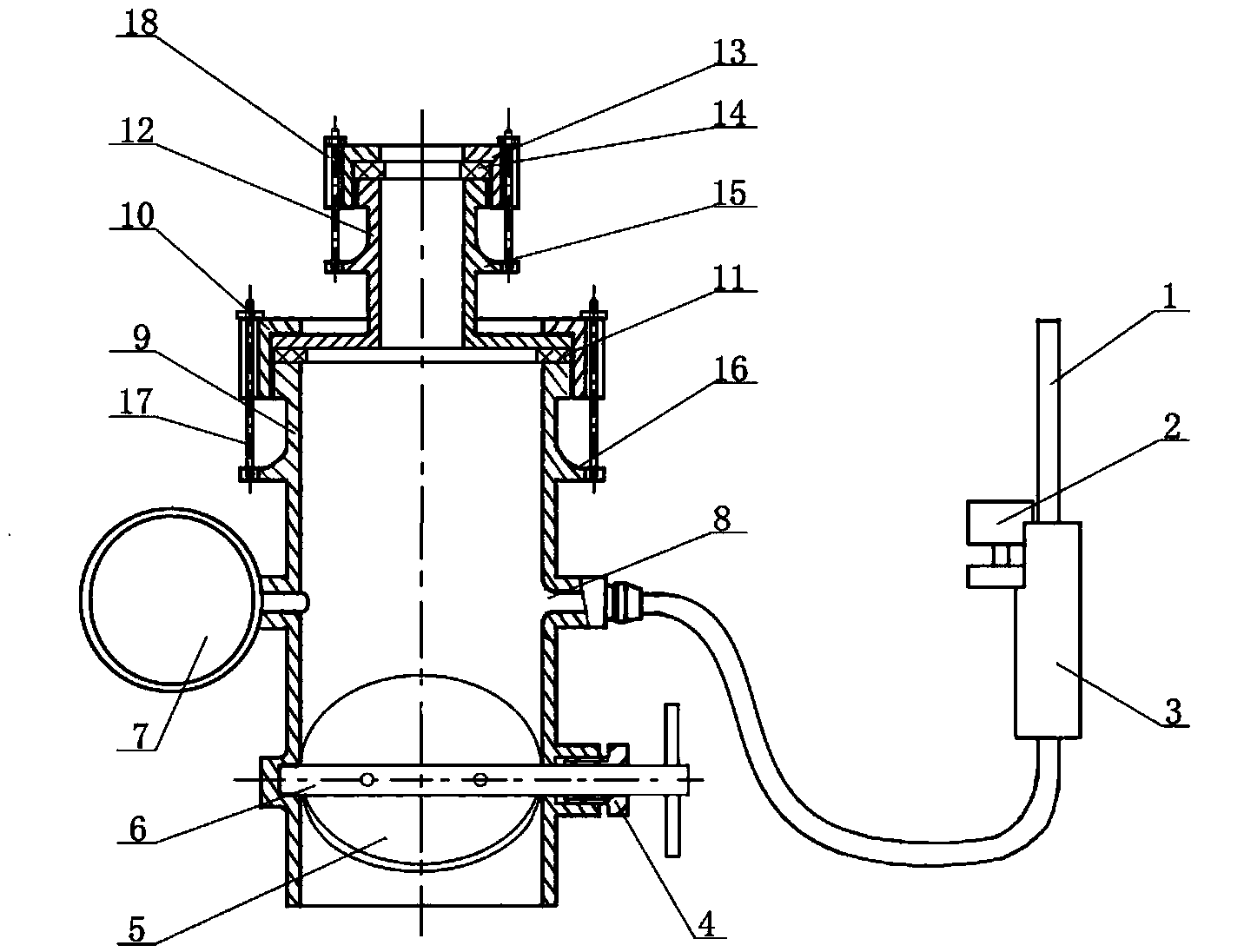

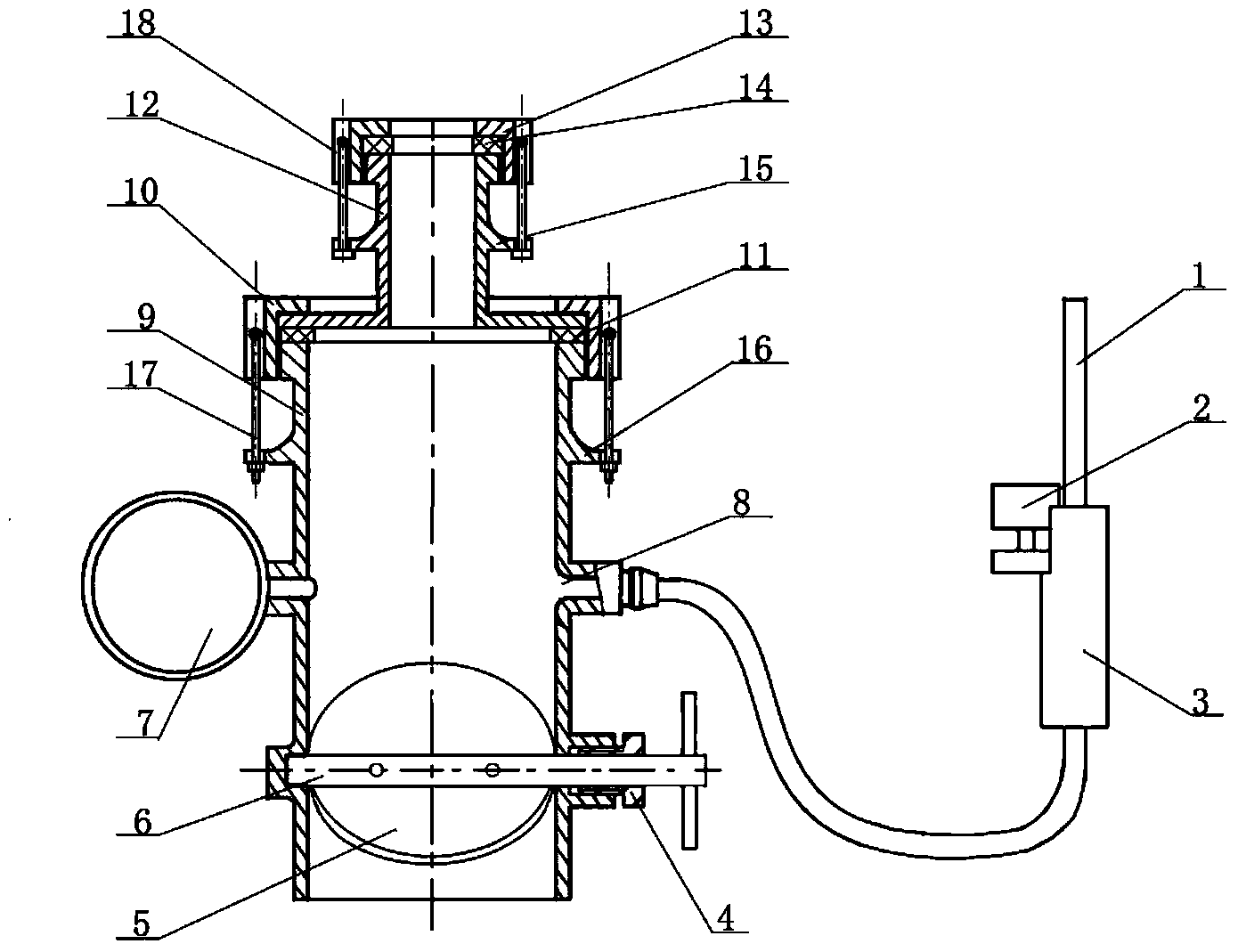

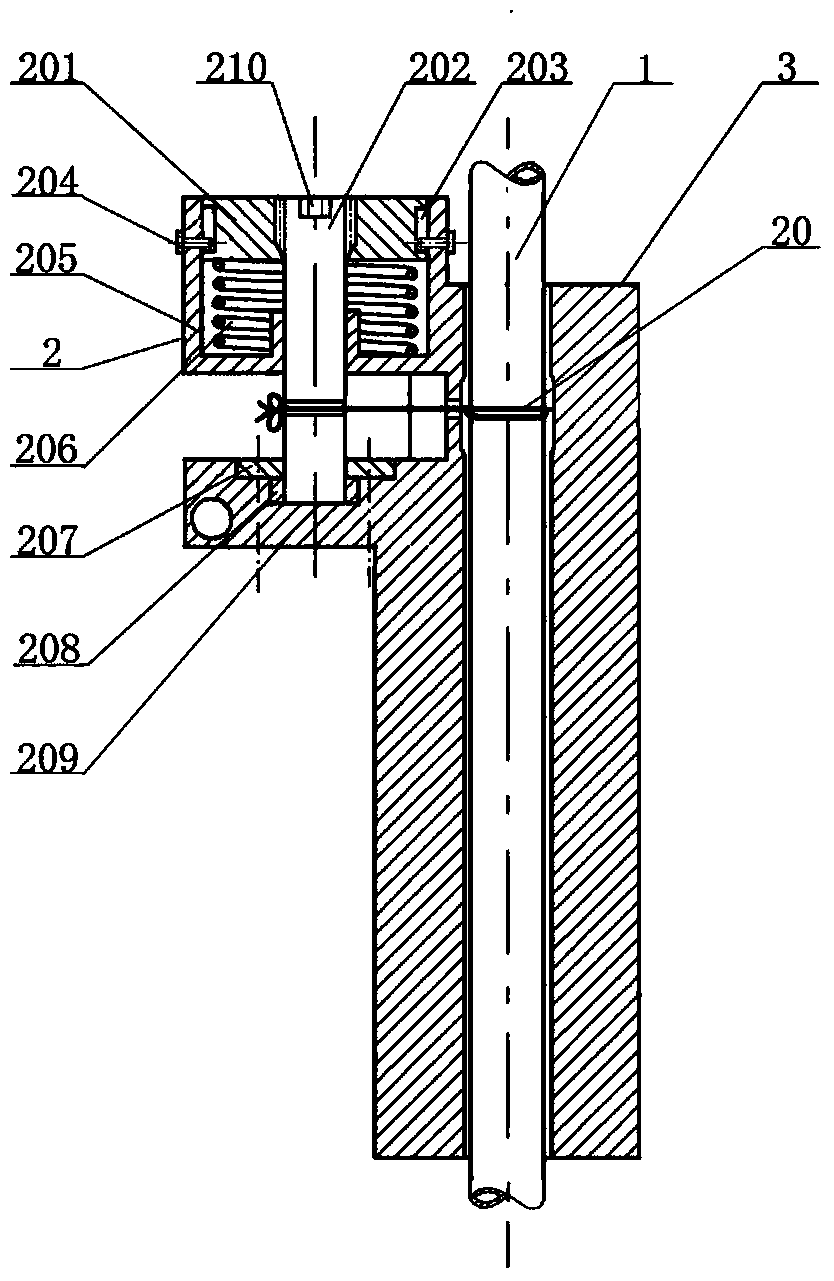

[0058] Such as figure 1 As shown, the sampler of the present invention includes a steady flow buffer pipe 9, a pump pipe connection mechanism, a diverter pressure regulating valve, a pressure gauge 7, a sampling hose 1, and a concentric flow regulator.

[0059] The steady flow buffer tube 9 is a cylindrical tube body made of 304 stainless steel with openings at both ends. Its upper port is provided with a convex edge and a pump tube connection mechanism to realize the fixation with the polluted water sample output pump tube. connect. A streamlined water outlet 8 is opened on the pipe wall of the steady flow buffer pipe 9 , and the sampling hose 1 is fixedly connected to the outer port of the streamlined water outlet 8 . The lower port of the steady-flow buffer pipe 9 is provided with a diverter pressure-regulating valve for adjusting the opening of the port of the steady-flow buffer pipe 9 to adjust the water flow pressure of the polluted water sample in the pipe body.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com