Method and device for estimating capability of resisting 'hydrogen poisoning'

A technology of hydrogen poisoning and ability, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effects of cost reduction, fast evaluation speed, convenient analysis and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

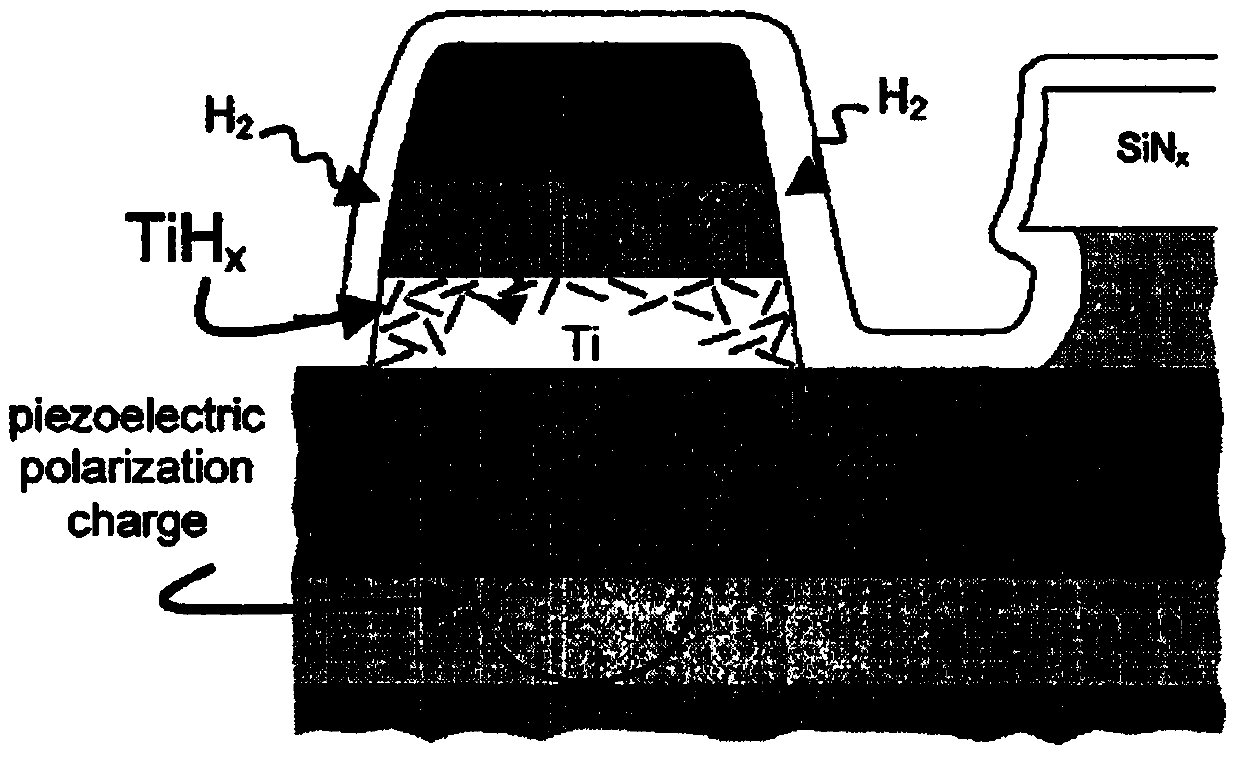

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with embodiments and accompanying drawings.

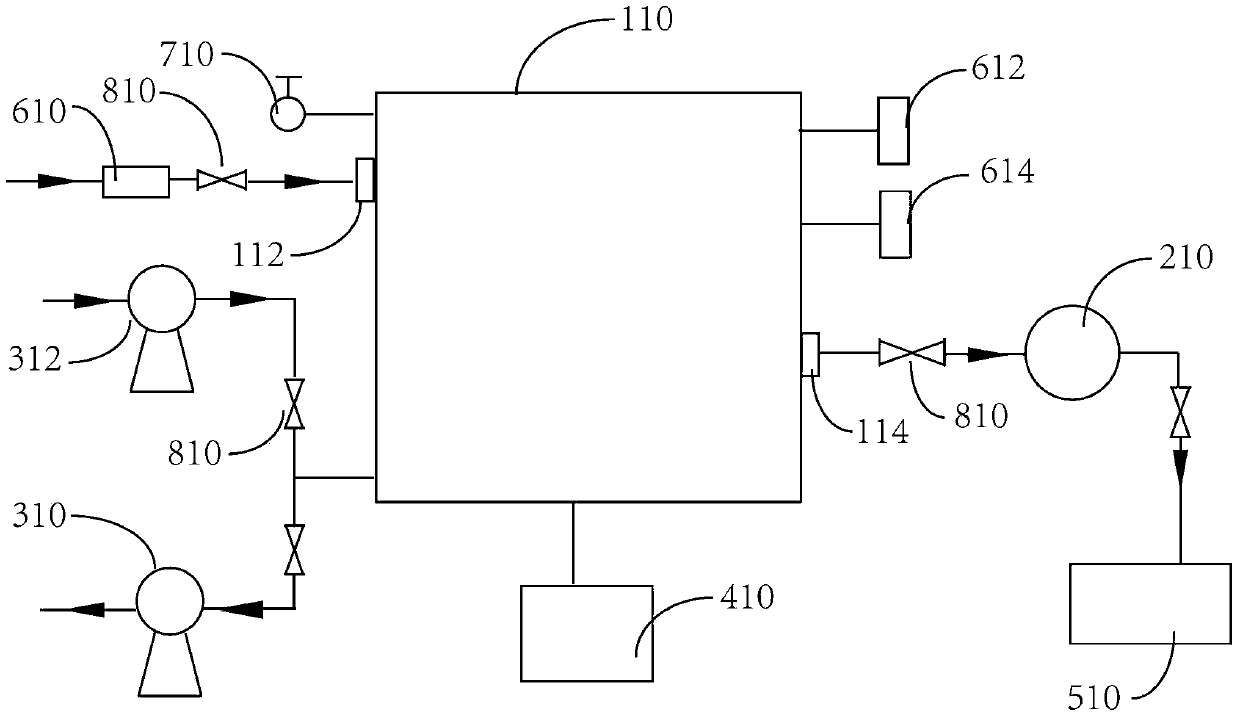

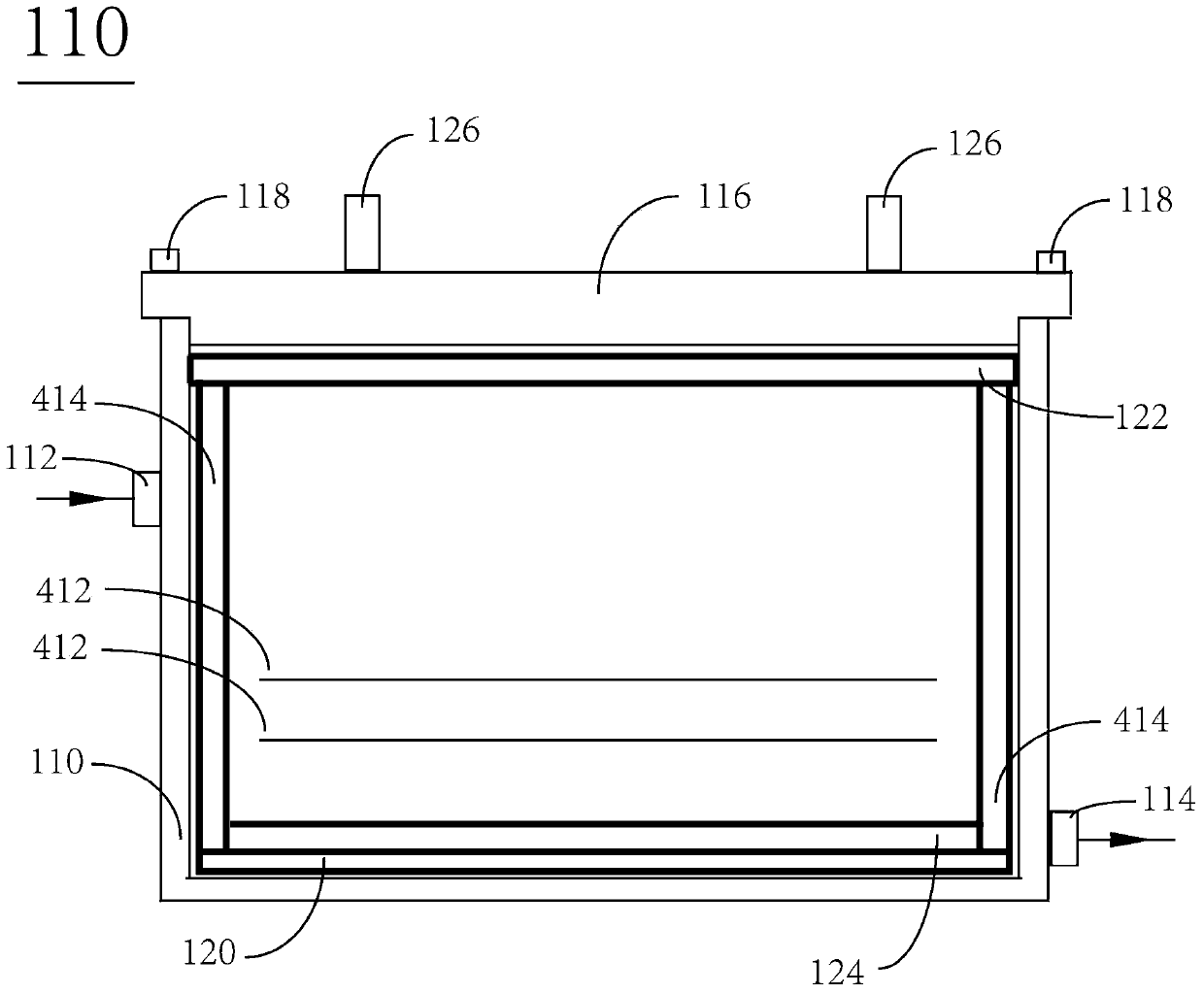

[0039] A device for evaluating the ability to resist "hydrogen poisoning", including a cavity 110, a sensing element, a sampling element 210, a vacuum element, a heating element 410, and an analysis element 510; the cavity 110 is connected with a safety valve 710, the The cavity 110 has an air inlet 112 and an air outlet 114. The cavity 110 is also provided with an opening, and the cavity 110 has a cover plate 116, a caliper 118 and a sealing ring matching the opening. The cavity 110 passes through The cover plate 116, the caliper 118 and the sealing ring are sealed, and a cover plate insulation layer 122 is also provided between the cover plate 116 and the cavity 110, and a handle 126 is also provided on the cover plate 116;

[0040] Both the sensing element and the vacuum element are connected to the cavity 110 through pipelines, the sensing element inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com