Method for preparing palladium nanocube

A cubic, nano-palladium technology, applied in the field of materials, can solve the problems of expensive equipment, severe reaction conditions, complicated preparation process, etc., and achieve the effects of simple structure, simple preparation process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The method disclosed by the present invention is a kind of preparation method of palladium nano cube, and its steps are:

[0024] (1) Dissolving vapreotide acetate in a hydrochloric acid solution with a pH of 1 to 3, and preparing 300 μL vapreotide acetate solution with a concentration of 0.1 to 0.2 mM;

[0025] (2) According to vapreotide acetate: the molar ratio of palladium chloride is 1:20~60 ratio, adds palladium chloride solution in the solution of step (1), is placed in the constant temperature metal bath of 60~80 ℃;

[0026] (3) by palladium chloride: the mol ratio of ascorbic acid is the ratio of 1:10~50, in the mixed solution of step (2), add the ascorbic acid solution of new preparation rapidly and reduce, and solution becomes dark brown gradually by light yellow, thereby Palladium nanocubes with regular shape and uniform particle size were obtained.

[0027] Among them, the concentration of palladium chloride solution is 4-6 mM, and the dosage is 800 μL; th...

Embodiment 1

[0030] Dissolve vapreotide acetate (Wuhan Dongkangyuan Technology Co., Ltd.) in hydrochloric acid solution with pH=3.0, and prepare 300 μL vapreotide acetate solution with a concentration of 0.1 mM; then add 800 μL of 6 mM chloropalladium acid solution, place in 15 min in a constant temperature metal bath at 80°C; finally, 40 μL of fresh 200 mM ascorbic acid solution was quickly added, and the mixed solution rapidly changed from light yellow to dark brown, namely delvapretide palladium nanocubes.

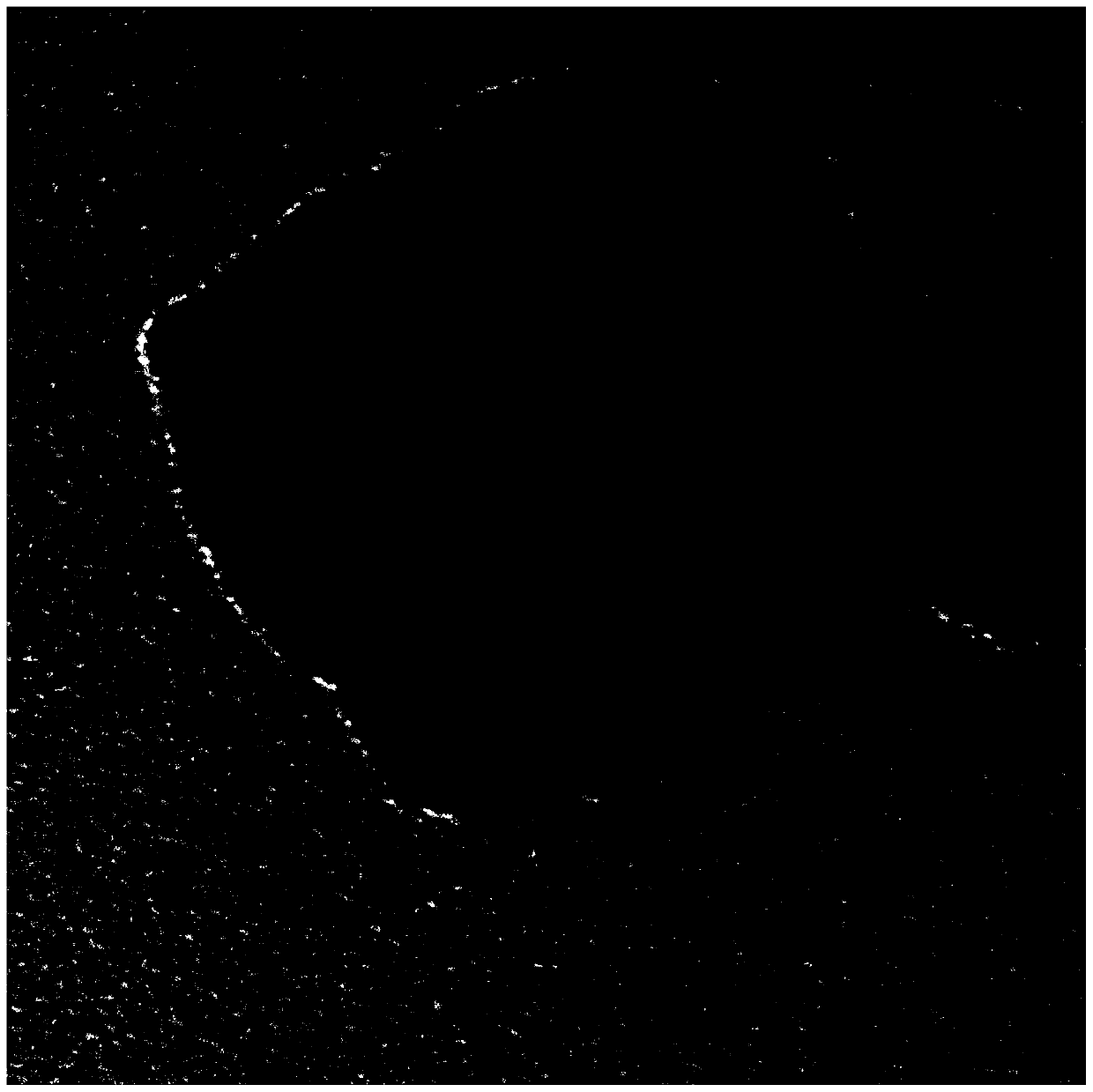

[0031] The morphology of silver-core-palladium-shell nanocubes was characterized by transmission electron microscopy, as shown in figure 1 As shown, the side length of the synthesized palladium nanocube is about 60nm, its shape is regular, and the metal and the template are well combined.

Embodiment 2

[0033] Dissolve vapreotide acetate (Wuhan Dongkangyuan Technology Co., Ltd.) in hydrochloric acid solution with pH=2.0, and prepare 300 μL vapreotide acetate solution with a concentration of 0.15 mM; then add 800 μL of 5 mM chloropalladium acid solution, place in 25 minutes in a constant temperature metal bath at 70°C; finally, 100 μL of fresh 100 mM ascorbic acid solution was quickly added, and the mixed solution rapidly changed from light yellow to dark brown, namely delvapretide palladium nanocubes.

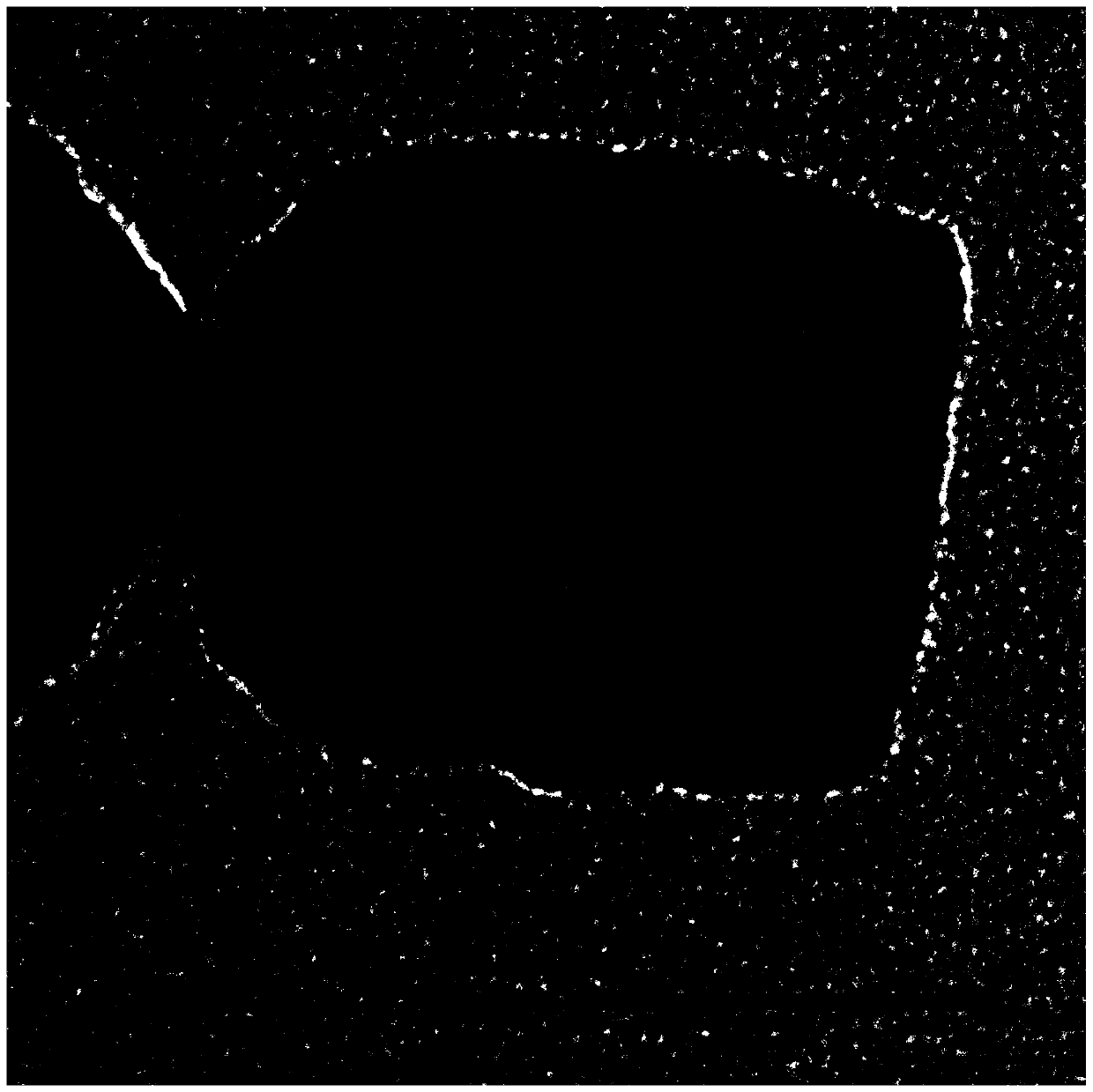

[0034] The morphology of silver-core-palladium-shell nanocubes was characterized by transmission electron microscopy, as shown in figure 2 As shown, the side length of the synthesized palladium nanocube is about 80nm, its shape is regular, and the metal and the template are well combined.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com