A steering gear applied to high temperature gas-cooled reactor

A high-temperature gas-cooled reactor and steering gear technology, applied in the field of reactor engineering, can solve problems such as inapplicability, and achieve the effects of easy adjustment, compact structure and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

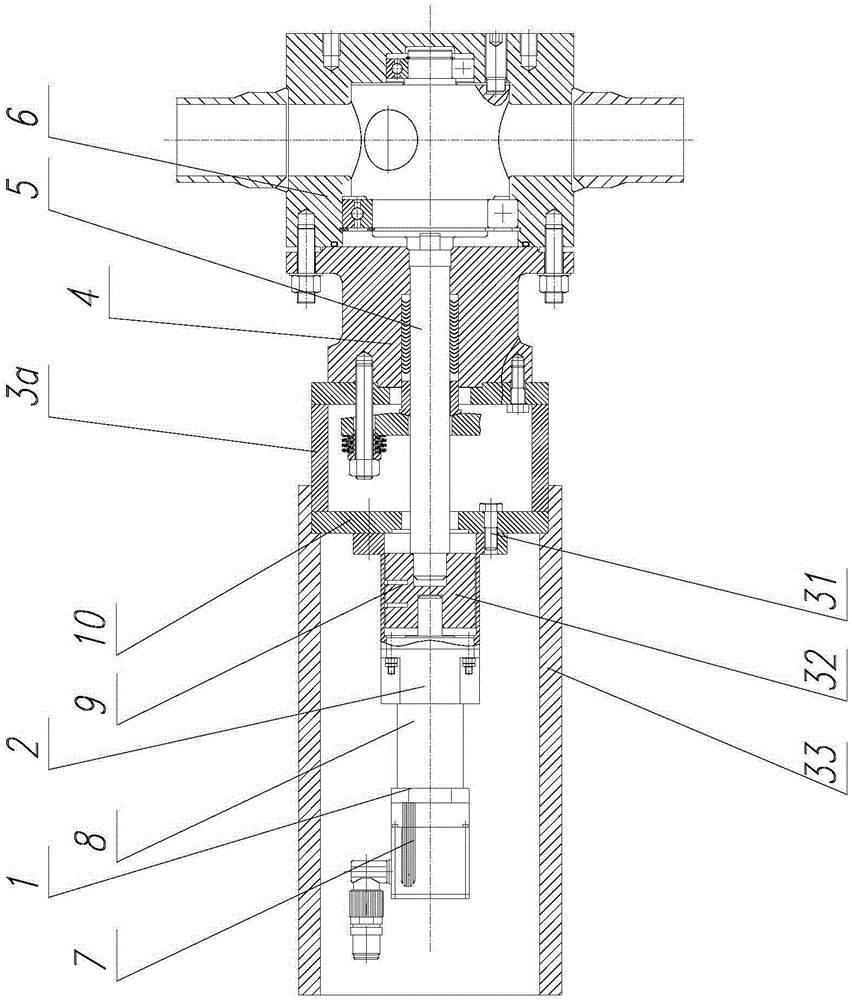

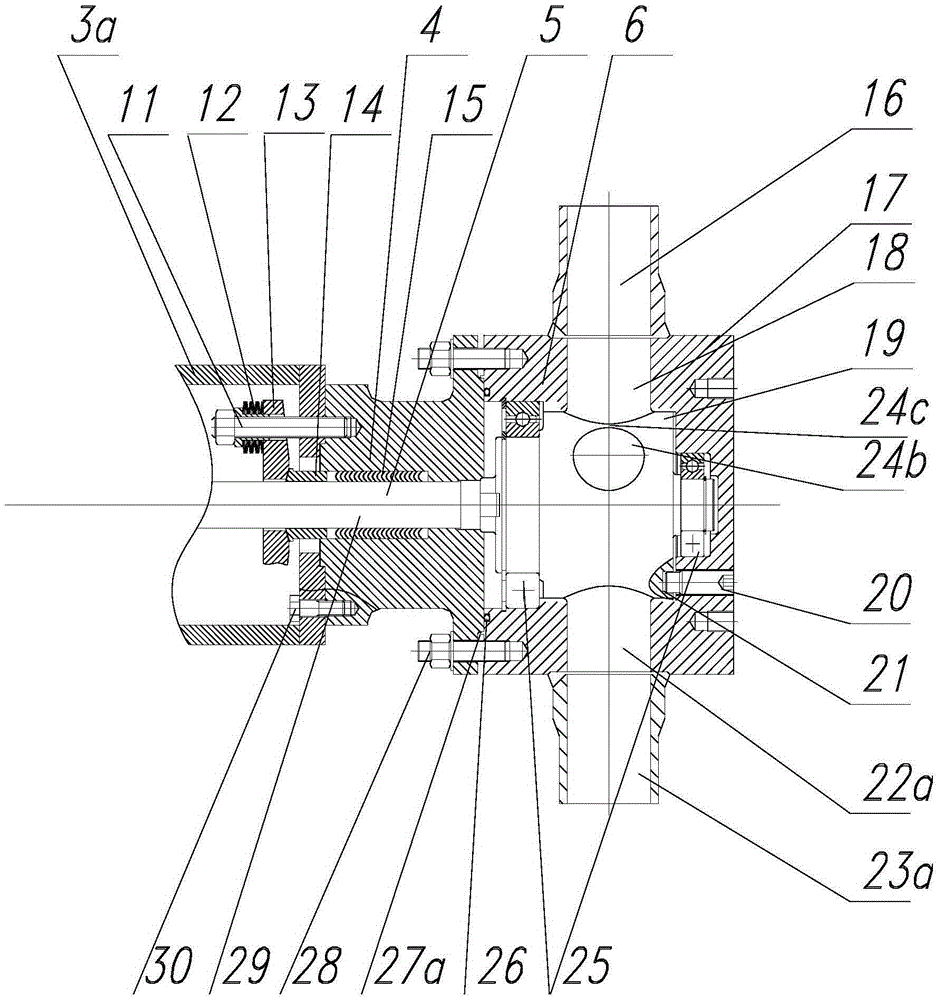

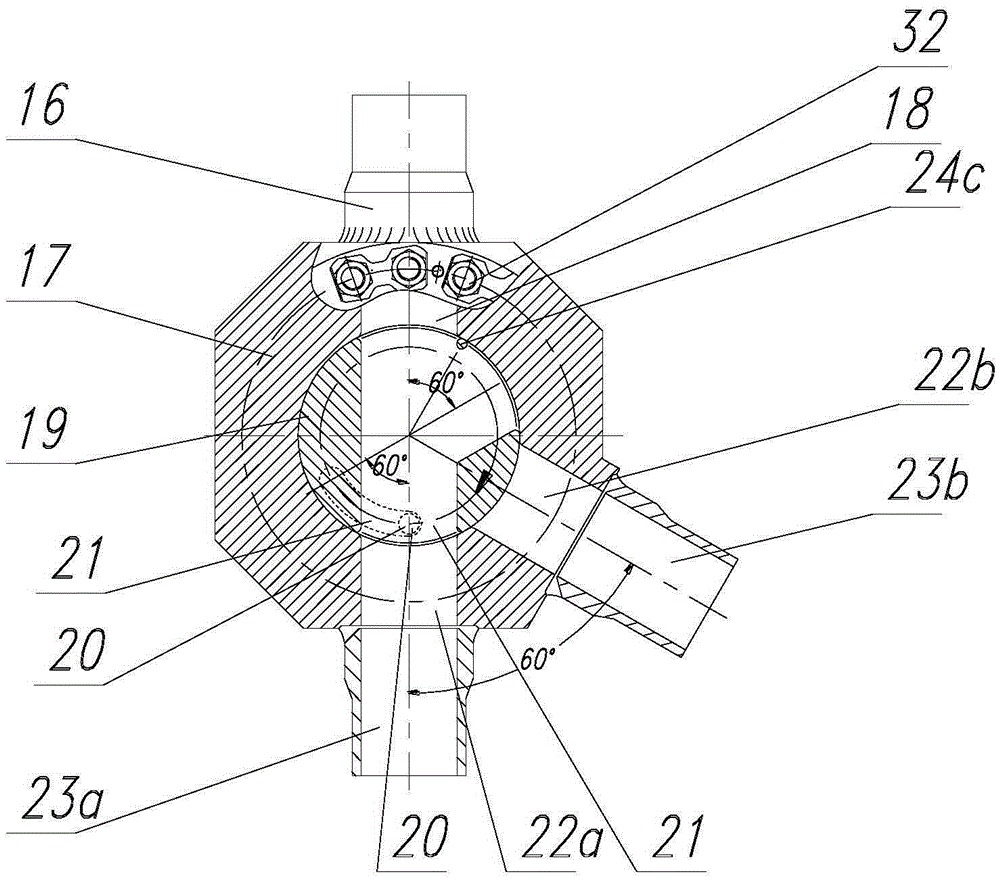

[0054] The embodiment of the present invention proposes a right steering gear applied to a high-temperature gas-cooled reactor based on a packing shaft seal, see figure 1 , the high-temperature gas-cooled reactor steering gear involved in the present invention includes a power component 1, a coupling assembly 2, a shaft seal connection assembly 3, a rotor assembly 5 and a casing assembly 6, wherein the shaft seal connection assembly 3a is a middle flange 4 is the middle flange connection assembly of the main body.

[0055] see figure 1 and figure 2 The shaft seal connection assembly 3a is composed of the bracket 10 and the middle flange 4 to form the connection body. The middle flange 4 has sufficient thickness, which can effectively prevent the spherical element from causing damage to the power component 1 due to axial accumulation and continuous radiation. The rotor includes a rotating drum 19 and a rotating shaft 29. The rotating drum 19 is placed in the sealed space for...

Embodiment 2

[0058] The embodiment of the present invention proposes a left steering gear applied to a high temperature gas-cooled reactor based on a magnetic drive without a shaft seal, see Figure 4 , The high temperature gas-cooled reactor steering gear involved in the present invention includes a power component 1, a coupling assembly 2, a shaft seal connection assembly 3, a rotor assembly 5 and a box assembly 6, wherein the shaft seal connection assembly is a magnetic drive 3b.

[0059] see Figure 4 and Figure 5 , The configuration and structure of the power component 1, the coupling assembly 2, the rotor assembly 5 and the box assembly 6 are the same as those in Embodiment 1, and the positional relationship and connection mode of each component are also basically the same. However, since this embodiment adopts the magnetic drive 3b as the shaft seal connection assembly, it is suitable for the seal transmission in the helium atmosphere. The isolation cover 37 of the magnetic drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com