A kind of preparation method of heat-not-burn cigarette block

A technology for heating non-combustion cigarettes, which is applied in the preparation of tobacco, tobacco, applications, etc., can solve the problems that are rarely mentioned about the preparation method of smoke materials for heating non-combustion cigarettes, and achieve large-scale production and easy preparation , the effect of increasing the number of pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

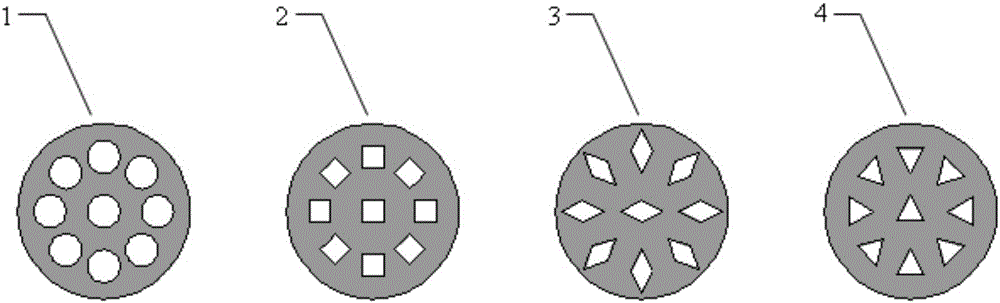

Image

Examples

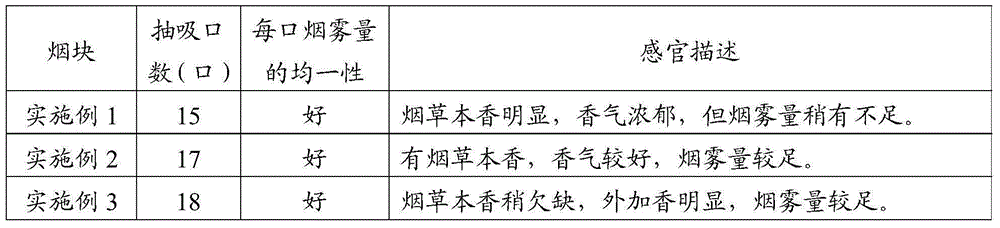

Embodiment 1

[0028] The preparation method of the heated non-combustion cigarette block described in the present embodiment comprises the following steps:

[0029] (1) Preparation of tobacco leaf powder: take flue-cured tobacco leaves whose moisture content is controlled at 6-13%, pulverize with a pulverizer and pass through a 40-mesh sieve to obtain tobacco leaf powder for use;

[0030] (2) Preparation of Tobacco Stem Ends: Take flue-cured tobacco stems with a moisture content of 5-13%, pulverize them with a pulverizer, and pass through a 40-mesh sieve to obtain tobacco stem ends, which are ready for use;

[0031] (3) Preparation of tobacco flavors: take Luo Han Guo extract 3%, cocoa shell extract 4%, locust bean extract 3%, grape seed extract 5%, apricot extract 3%, alfalfa extract 5%, monk Cap Flower Extract 5%, Lemon Oil 6%, Red Date Extract 5%, Valerian Root Extract 3%, Lentil Leaf Extract 4%, Cherry Extract 8%, Apple Extract 6%, Deionized Water 15% and 25% propylene glycol, after mi...

Embodiment 2

[0036] The preparation method of the heated non-combustion cigarette block described in the embodiment comprises the following steps:

[0037] (1) Preparation of tobacco leaf powder: take flue-cured tobacco leaves whose moisture content is controlled at 6-13%, pulverize with a pulverizer and pass through a 40-mesh sieve to obtain tobacco leaf powder for use;

[0038] (2) Preparation of Tobacco Stem Ends: Take flue-cured tobacco stems with a moisture content of 5-13%, pulverize them with a pulverizer, and pass through a 40-mesh sieve to obtain tobacco stem ends, which are ready for use;

[0039](3) Preparation of tobacco flavors: take Luo Han Guo extract 3%, cocoa shell extract 4%, locust bean extract 3%, grape seed extract 5%, apricot extract 3%, alfalfa extract 5%, monk Cap Flower Extract 5%, Lemon Oil 6%, Red Date Extract 5%, Valerian Root Extract 3%, Lentil Leaf Extract 4%, Cherry Extract 8%, Apple Extract 6%, Deionized Water 15% and 25% propylene glycol, after mixing the ...

Embodiment 3

[0044] The preparation method of the heated non-combustion cigarette block described in the embodiment comprises the following steps:

[0045] (1) Preparation of tobacco leaf powder: take flue-cured tobacco leaves whose moisture content is controlled at 6-13%, pulverize with a pulverizer and pass through a 40-mesh sieve to obtain tobacco leaf powder for use;

[0046] (2) Preparation of Tobacco Stem Ends: Take flue-cured tobacco stems with a moisture content of 5-13%, pulverize them with a pulverizer, and pass through a 40-mesh sieve to obtain tobacco stem ends, which are ready for use;

[0047] (3) Preparation of tobacco flavors: take Luo Han Guo extract 3%, cocoa shell extract 4%, locust bean extract 3%, grape seed extract 5%, apricot extract 3%, alfalfa extract 5%, monk Cap Flower Extract 5%, Lemon Oil 6%, Red Date Extract 5%, Valerian Root Extract 3%, Lentil Leaf Extract 4%, Cherry Extract 8%, Apple Extract 6%, Deionized Water 15% and 25% propylene glycol, after mixing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com