Flexible and high-energy-absorbing stab and cut resistant shoe sole

A high-energy, stab-proof technology, used in shoe soles, footwear, applications, etc., can solve the problems of anti-jab piercing, anti-knife cutting, and poor anti-needle performance, and achieves simple production, improved safety level, and stable molding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A kind of flexible and high-energy-absorbing puncture-resistant sole for construction sites

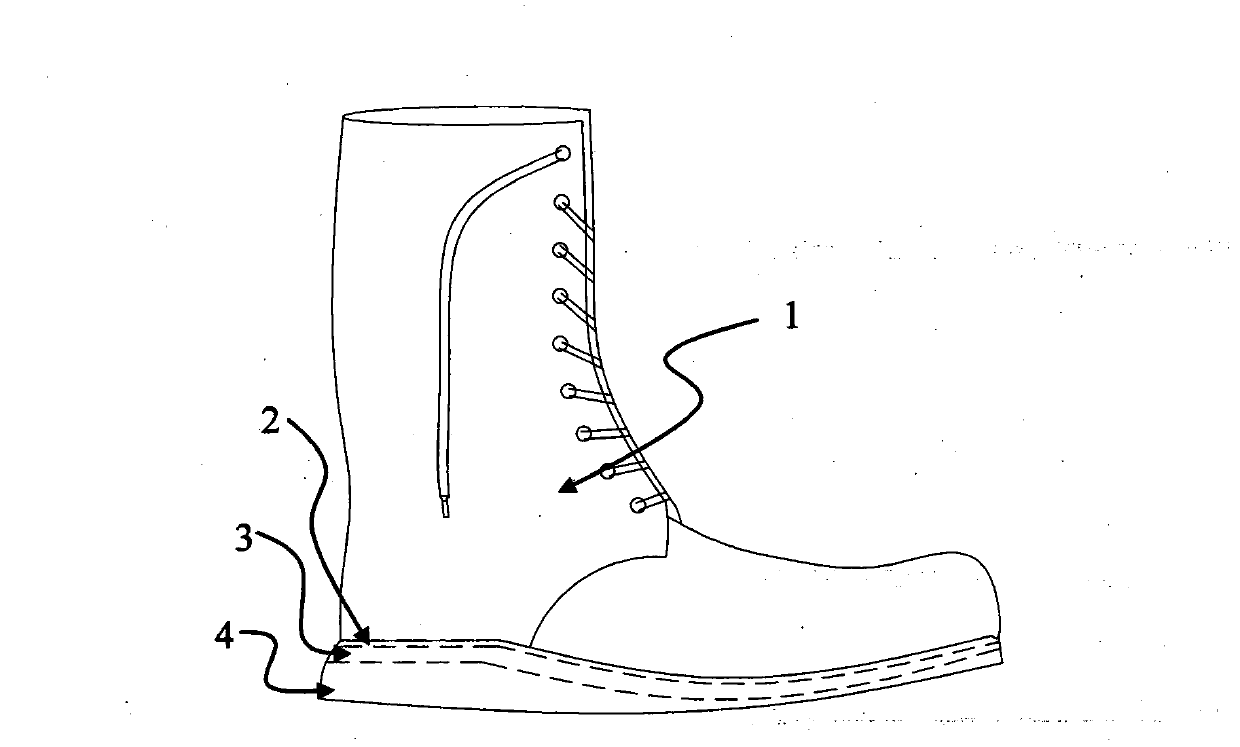

[0037] A flexible and high-energy-absorbing puncture-resistant shoe sole for construction sites includes an inner bottom 2 , a puncture-resistant composite layer 3 and an outer bottom 4 . The inner bottom 2, the anti-stab composite layer 3 and the outer bottom 4 are prepared into anti-puncture soles according to the following steps.

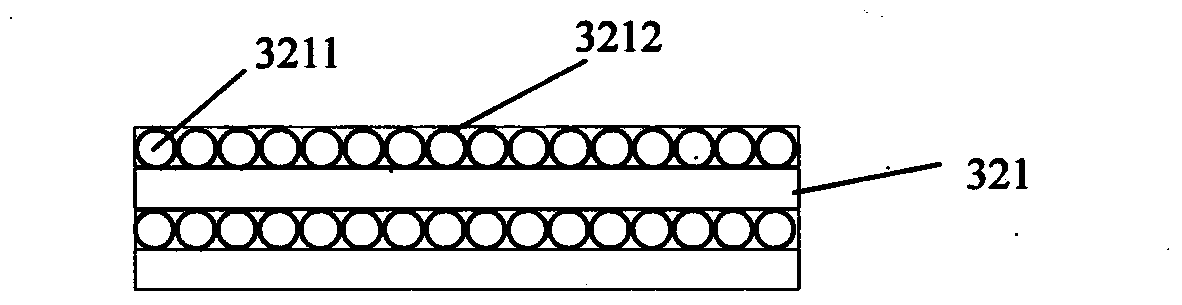

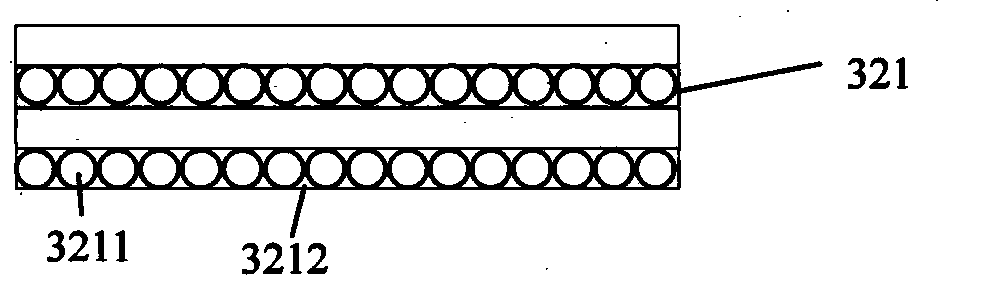

[0038] Described inner bottom 2 selects polyester / cotton fabric for use, and the square meter weight of fabric is 100g / m 2 , the light pressure thickness of fabric is 0.2mm; Described anti-stab composite layer 3 comprises woven fabric layer 31, no weft cloth layer 32 and restriction layer 33, and described restriction layer 33 is steel wire plain weave woven fabric, and steel wire diameter is 1mm , the arrangement density of the steel wires is 10 / 10cm; the woven fabric layer 31 is composed of 12 ultra-high molecular weight polyethylene...

Embodiment 2

[0040] Embodiment 2 A flexible and high-energy-absorbing puncture-resistant sole for railway construction sites

[0041] A flexible and high-energy-absorbing puncture-resistant shoe sole for railway construction sites includes an inner bottom 2 , a puncture-resistant composite layer 3 and an outer bottom 4 . The inner bottom 2, the anti-stab composite layer 3 and the outer bottom 4 are prepared into anti-puncture soles according to the following steps.

[0042] Described inner bottom 2 selects polyester / cotton fabric for use, and the square meter weight of fabric is 160g / m 2 The light pressure thickness of fabric is 0.25mm; Described anti-stab composite layer 3 comprises woven fabric layer 31, no weft cloth layer 32 and restriction layer 33, and described restriction layer 33 is steel wire plain weave woven fabric, and steel wire diameter is 0.5 mm, the steel wire arrangement density is 20 / 10cm; the woven fabric layer 31 is formed by 16 ultra-high molecular weight polyethylen...

Embodiment 3

[0044] Embodiment 3 A flexible and high-energy-absorbing puncture-resistant sole for jungle construction sites

[0045] A flexible and high-energy-absorbing puncture-resistant shoe sole for jungle construction sites includes an inner bottom 2, a puncture-resistant composite layer 3 and an outer bottom 4. The inner bottom 2, the anti-stab composite layer 3 and the outer bottom 4 are prepared into anti-puncture soles according to the following steps.

[0046] Described inner bottom 2 selects polyester / cotton fabric for use, and the square meter weight of fabric is 100g / m 2 The light pressure thickness of fabric is 0.2mm; Described anti-stab composite layer 3 comprises woven fabric layer 31, no weft cloth layer 32 and restriction layer 33, and described restriction layer 33 is steel wire plain weave woven fabric, and steel wire diameter is 2mm , the arrangement density of the steel wires is 10 / 10cm; the woven fabric layer 31 is formed by 12 pieces of ultra-high molecular weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com