Cleaning method and cleaning system of centrifuge filter cloth in wire cutting waste mortar recycling

A cleaning system and technology for waste mortar, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of high residual impurity content, incomplete cleaning of scraper filter cloth, and no polyethylene glycol impurities cleaning system, etc. To achieve the effect of simple steps, cost saving, and increase the number of reciprocating use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

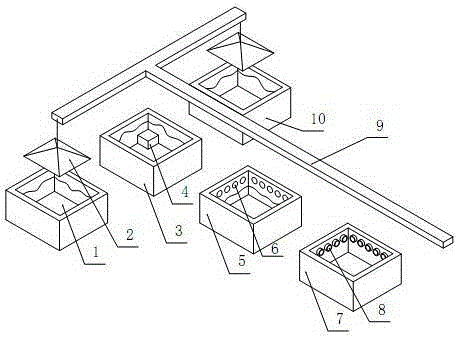

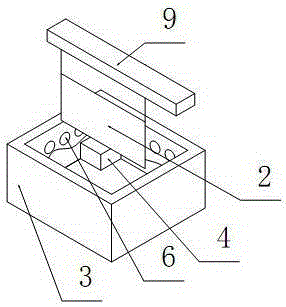

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: a kind of cleaning method of centrifuge filter cloth in the recycling of wire cutting waste mortar, concrete steps comprise:

[0038] (1) Alkali washing: Soak the filter cloth in an alkaline solution containing 2%~3% by mass for 20~30 minutes, then clean it to obtain filter cloth A, and apply ultrasonic waves at a frequency of 28~60KHz to filter cloth A Shock treatment for 20-30 minutes to precipitate fine powder and polyethylene glycol until the pH value of the rinse solution after washing is neutral, and filter cloth B is obtained;

[0039] (2) Pickling: Soak the filter cloth B in an acid solution containing 2% to 3% by mass for 20 to 30 minutes, then wash to obtain a filter cloth C, which is subjected to ultrasonic waves at a frequency of 28 to 60KHz Shock treatment for 20 to 30 minutes to precipitate fine powder and polyethylene glycol until the pH value of the rinse solution after washing is neutral, and filter cloth D is obtained;

[0040] (3) Rinse...

Embodiment 2

[0048]Embodiment 2: the cleaning method of centrifuge filter cloth in a kind of line cutting waste mortar recovery, concrete steps comprise:

[0049] (1) Pickling: Soak the filter cloth in an acid solution containing 2%~3% by mass for 20~30 minutes, then wash it to obtain filter cloth F, and precipitate fine powder and polyethylene glycol until it is washed The pH value of the flushing solution is neutral, and the filter cloth G is obtained;

[0050] (2) Ultrasonic oscillation: Ultrasonic oscillation at a frequency of 28-60KHz is performed on the filter cloth G for 20-30 minutes to separate out the remaining fine powder and polyethylene glycol in the filter cloth G to obtain the filter cloth H; (3) Rinse: Rinse the filter cloth H with clean water until the pH value of the rinsing solution is neutral to obtain the filter cloth I; (4) Drying: (4) Dry the filter cloth I. The drying method can be drying or air drying.

[0051] In this embodiment, the preferred oscillation freque...

Embodiment 3

[0052] Embodiment 3: the cleaning method of centrifuge filter cloth in a kind of line cutting waste mortar recovery, comprises the steps:

[0053] (1) Ultrasonic vibration: The filter cloth is subjected to ultrasonic vibration treatment at a frequency of 28-60KHz for 20-30 minutes, for example: 22 minutes, 25 minutes, and 27 minutes, to separate out the remaining fine powder and polyethylene glycol in the filter cloth, and obtain Filter cloth J;

[0054] (2) Rinse: Rinse the filter cloth J with clean water until the pH value of the rinsing liquid is neutral to obtain the filter cloth K;

[0055] (3) Drying: The filter cloth K is dried. The drying method can be drying or air drying.

[0056] In order to see the comparison more conveniently, the three filter cloths cleaned in Example 1-3 and one unused filter cloth were used, and four scrapers were used to install the four filter cloths, and the same raw materials were selected, and the four scrapers started Using the scraper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com