Method of laser-welding metal materials by double lasers

A technology of dual lasers and metal materials, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as complex process, line difference, and non-adjustable energy ratio, and achieve the effect of promoting absorption rate and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

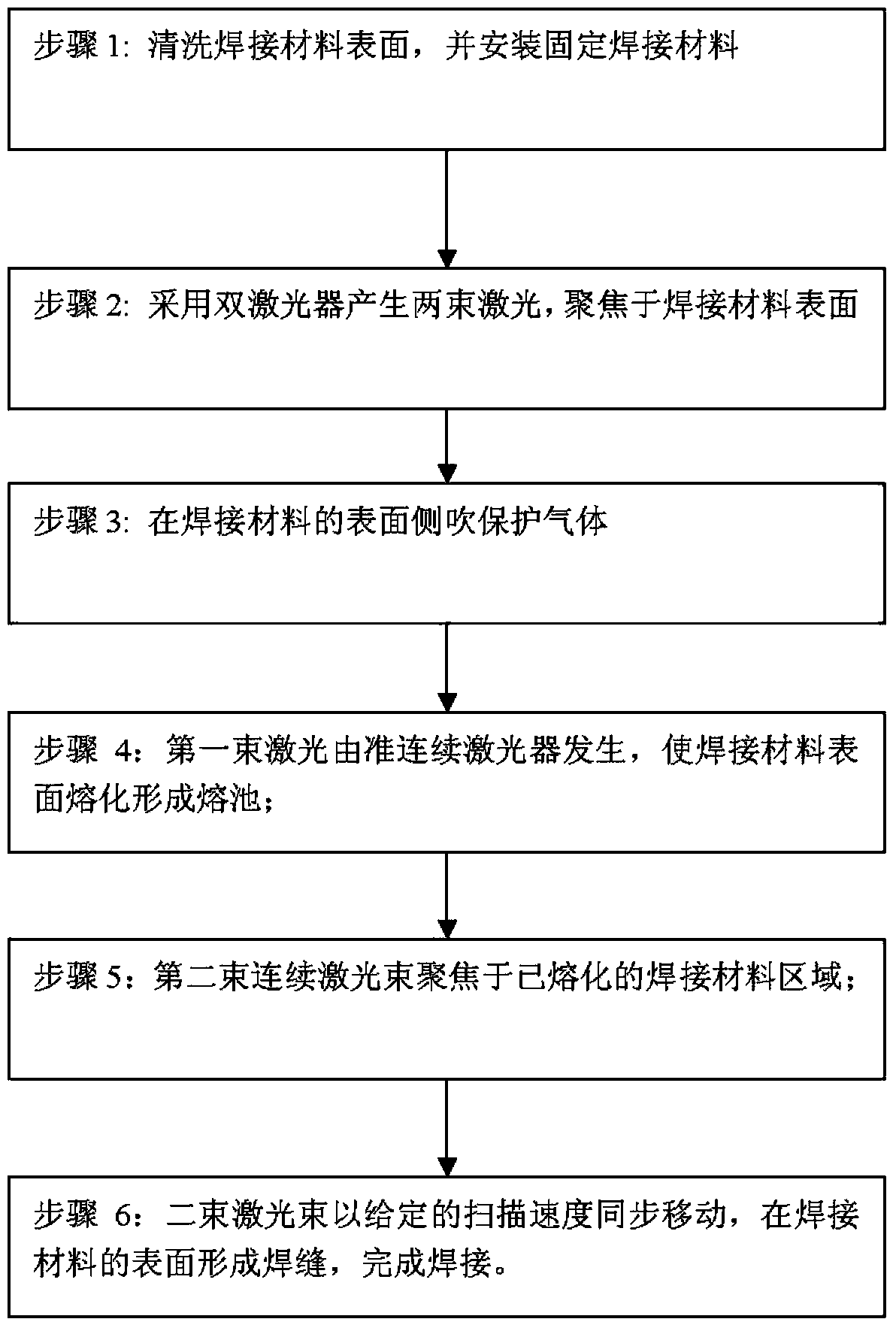

[0015] see figure 1 As shown, the present invention provides a method for implementing laser welding of metal materials using dual lasers, comprising the following steps:

[0016] Step 1: Clean up the welding material with sandpaper, install and fix the welding material on the welding platform, and it is ready.

[0017] Step 2: Two laser beams are used to generate two laser beams, and the two laser beams are focused on the surface of the welding material. The two laser beams are respectively a quasi-continuous laser and a continuous laser. The maximum output power of the quasi-continuous laser is 100-500W, and the pulse width is 50-200ns, repetition frequency 10kHz-30kHz, peak power greater than 10 5 W, the maximum output power of the continuous laser is 500-10000W, and the welding material is aluminum alloy, copper alloy, pure aluminum or pure copper material;

[0018] Due to the high reflectivity of aluminum alloys and copper alloys, it is not easy to form molten pools for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com