Anti-adhesive composition, anti-adhesive treatment method for mold and mold

A processing method and composition technology, which can be applied in the direction of metal material coating process, coating, melting spray plating, etc., can solve the problems of polluting the environment, Teflon curing temperature mold deformation, and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

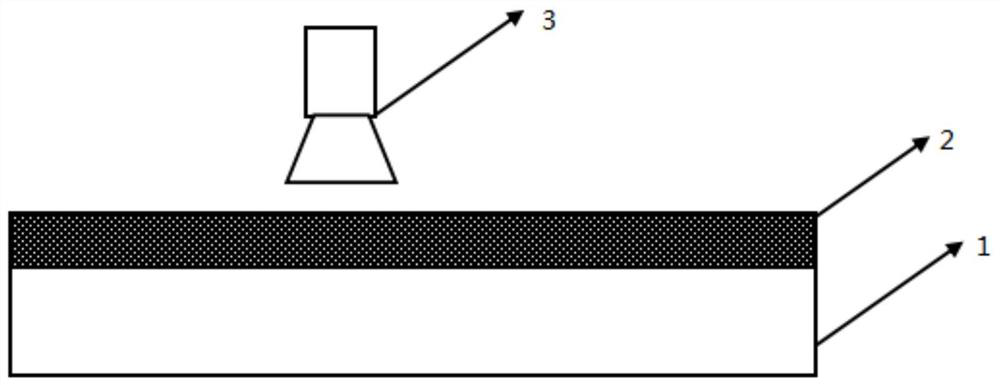

Image

Examples

Embodiment 1

[0023] This embodiment provides a kind of anti-sticking processing method of mould, and it comprises the following steps:

[0024] S1. Weigh 5g of zirconia micropowder, 5g of titanium oxide micropowder, 5g of yttrium oxide micropowder, and 70g of methyl MQ silicone resin powder, and set aside. Wherein, the particle diameter of zirconia micropowder is 35 microns; The particle diameter of titanium oxide micropowder is 20 microns; The particle diameter of yttrium oxide micropowder is 30 microns; The structural formula of methyl MQ silicone resin is [(CH 3 ) 3 SiO 1 / 2 ] a [SiO 4 / 2 ] b , wherein a:b=0.6:1, that is, the molar ratio of M to Q is 0.6:1.

[0025] S2. After mixing the above-mentioned zirconia micropowder, titania micropowder, yttrium oxide micropowder, and methyl MQ silicone resin powder, use a high-speed mixer to stir and disperse for 5 minutes under the condition of 200r / min to obtain a uniform powder Anti-adhesive composition, ready for use.

[0026] S3, as at...

Embodiment 2

[0028] This embodiment provides a kind of anti-sticking processing method of mould, and it comprises the following steps:

[0029] S1. Weigh 12g of zirconia micropowder, 18g of titanium oxide micropowder, 10g of yttrium oxide micropowder, and 40g of methyl MQ silicone resin powder, and set aside. Wherein, the particle diameter of zirconia micropowder is 45 microns; The particle diameter of titanium oxide micropowder is 30 microns; The particle diameter of yttrium oxide micropowder is 40 microns; The structural formula of methyl MQ silicone resin is [(CH 3 ) 3 SiO 1 / 2 ] a [SiO 4 / 2 ] b , wherein a:b=0.9:1, that is, the molar ratio of M to Q is 0.9:1.

[0030] S2. Mix the zirconia micropowder, titania micropowder, yttrium oxide micropowder, and methyl MQ silicone resin powder weighed above, and then use a high-speed mixer to stir and disperse for 5 minutes under the condition of 500r / min to obtain a uniform powder. Anti-adhesive composition, ready for use.

[0031] S3, as ...

Embodiment 3

[0033] This embodiment provides a kind of anti-sticking processing method of mould, and it comprises the following steps:

[0034] S1. Weigh 7g of zirconia micropowder, 6g of titanium oxide micropowder, 6g of yttrium oxide micropowder, and 65g of methyl MQ silicone resin powder, and set aside. Wherein, the particle diameter of zirconia micropowder is 40 microns; The particle diameter of titanium oxide micropowder is 25 microns; The particle diameter of yttrium oxide micropowder is 35 microns; The structural formula of methyl MQ silicone resin is [(CH 3 ) 3 SiO 1 / 2 ] a [SiO 4 / 2 ] b , wherein a:b=0.7:1, that is, the molar ratio of M to Q is 0.7:1.

[0035] S2. After mixing the above-mentioned zirconia micropowder, titania micropowder, yttrium oxide micropowder, and methyl MQ silicone resin powder, use a high-speed mixer to stir and disperse for 5 minutes under the condition of 300r / min to obtain a uniform powder Anti-adhesive composition, ready for use.

[0036] S3, as at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com