A Surface Treatment Method for Improving the Bonding Performance of Multilayer Plating Materials

A technology of surface treatment and multi-layer plating, which is applied in welding equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of lack of laser surface treatment solutions, insufficient and other problems, and meet strength requirements, improve surface roughness, and meet air tightness requirements. The effect of sexual demands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. The processing equipment and materials involved in this embodiment

[0050] (1) The laser uses an IPG fiber laser, which emits a pulsed laser with a wavelength of 1064nm and a pulse width of 200ns (fixed and non-adjustable).

[0051] (2) The CPM material is a multi-layer composite material of copper, molybdenum-copper, and tungsten-copper core materials. It has high thermal conductivity, and the coefficient of thermal expansion (CTE) is easy to adjust. It is easy to match with Kovar alloy and alumina ceramics. It is currently the mainstream Heat dissipation substrate for high-power chips. CPC is a kind of CPM material. The default CPC core material in the industry refers to Mo70Cu30 material. Because copper (Cu) is easily oxidized and corroded in the air, which affects the life of CPC core material, nickel (Ni), Gold (Au) coats its surface to extend the lifetime of the CPC. In the field of electronic packaging, the connection between CPC and lead frame, its reliabili...

Embodiment approach 1

[0055] Using the first laser with power of 5W and frequency of 60KHz, and the second laser with power of 15W and frequency of 40KHz, the surface of the CPC multilayer coating material was treated according to the surface treatment method of the present invention to obtain sample one.

[0056] Using a laser with a power of 15W and a frequency of 40KHz, the surface of the CPC multilayer coating material was treated according to the surface treatment method in the prior art, and sample 2 was obtained.

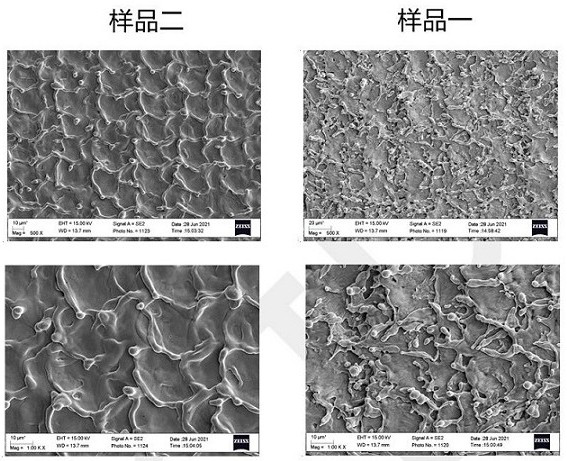

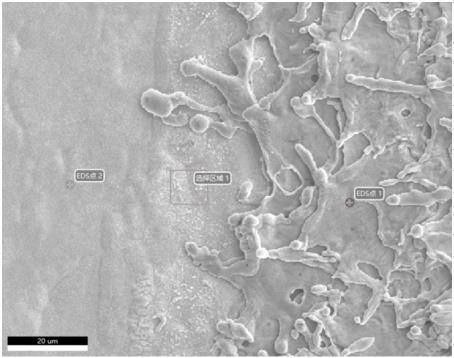

[0057] Sample 1 and sample 2 were tested for microstructure, bonding area strength and packaging airtightness respectively:

[0058] (1) Microstructure detection

[0059] see Figure 2-Figure 4 As shown, among them, figure 2 is the surface microscopic topography of sample 1 and sample 2; image 3 Sampling diagram for sample-surface EDS detection; Figure 4 It is the EDS detection spectrogram; Table 2 is the EDS detection quantitative result table.

[0060] During the bonding...

Embodiment approach 2

[0077] Adopting power is 5W, and the frequency is the first laser of 60KHz, and power is 15W, and the frequency is the second laser of 40KHz, according to the surface treatment method of the present invention, the surface of two CPC multilayer coating materials is processed respectively, obtains sample three And sample four, the difference is: the area layer in the step (S1) followed by sample three, where the line spacing between the filled lines is 0.03mm (less than 0.05mm); in the step (S1) followed by sample four Area layers where the line spacing between filled lines is 0.1mm (greater than 0.05mm).

[0078] refer to Image 6 and as shown in Table 4, Image 6 It is the optical photo of sample 3 and sample 4, and Table 4 is the comparison table of the results of sample 3 and sample 4. According to Embodiment 2, in the step (S1) of the present invention, the line spacing between the filling lines of the surface treatment area layer is less than 0.05mm, and the function is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com