A method for forming an organic-inorganic combination hood for a remote sensing camera

A technology of remote sensing camera and molding method, applied in 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve problems such as weak combination, increased cost, and low dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

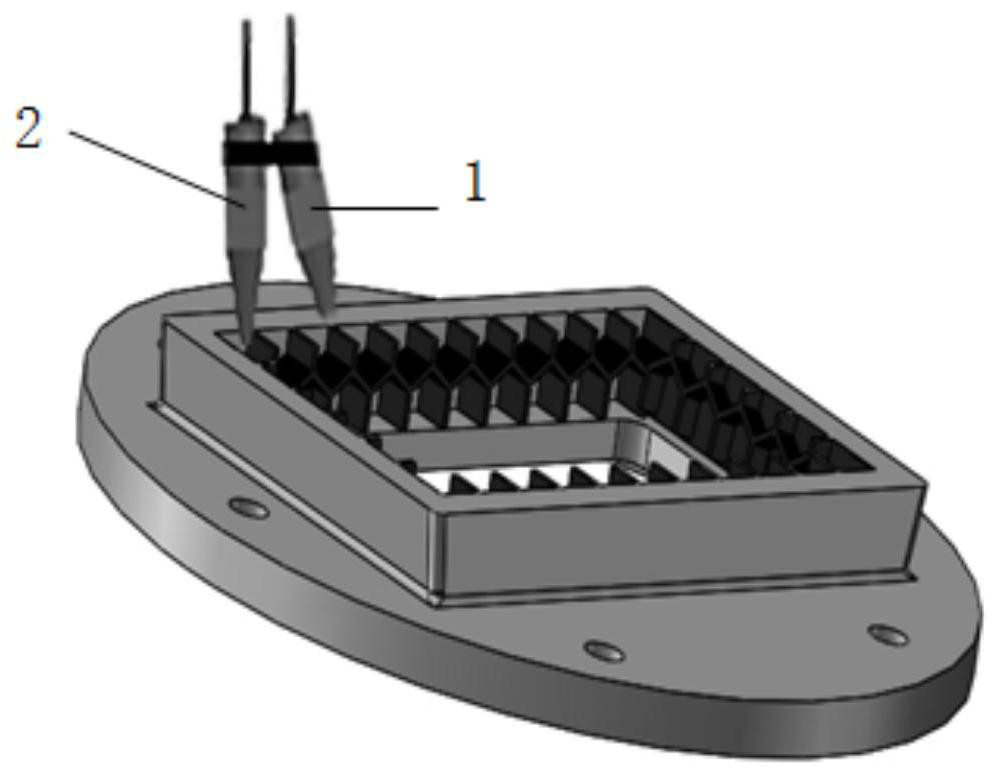

[0055] Example 1: A PEEK shading mask formed by spraying without a spray gun. The organic substrate is PEEK. The molding temperature is controlled at 420°C, the speed is 25mm / s, and the extrusion volume is 120%. Under these conditions, a shading with an absorption rate of 95.83% is obtained. cover, such as Figure 7 shown.

example 2

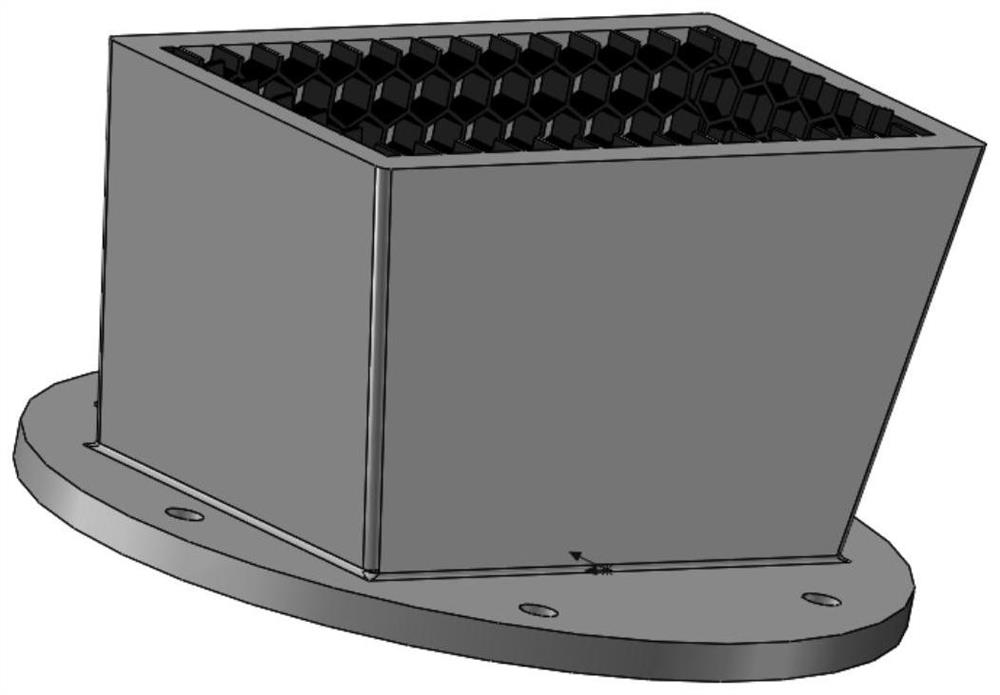

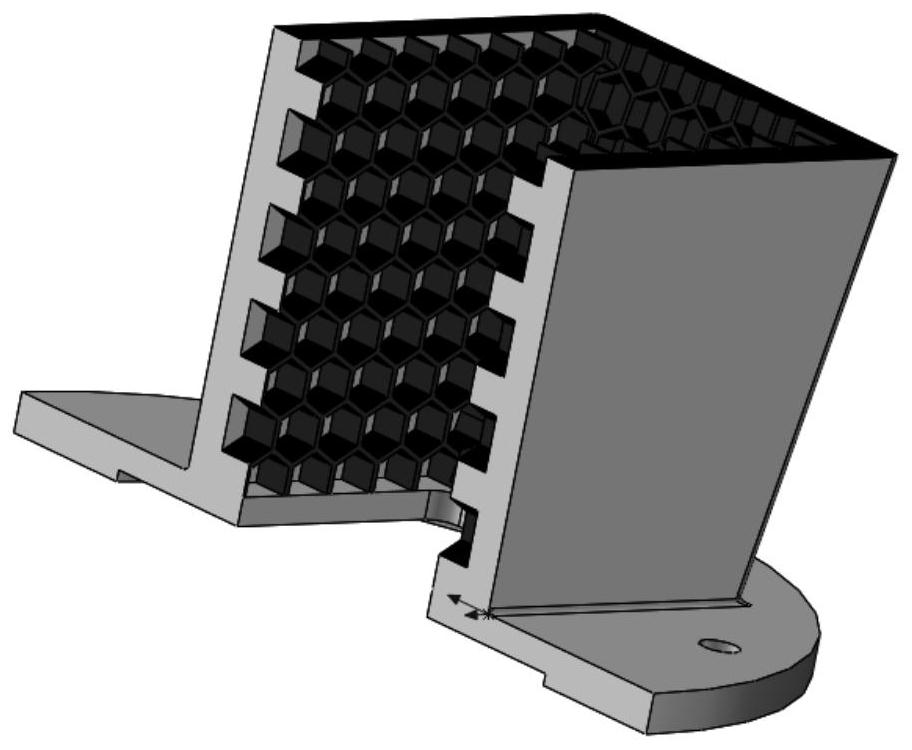

[0056] Example 2: PEEK is used as the base material of the organic light shield, and the carbon black solution (40mg / mL) with ethanol as the solvent is used as the inorganic black paint. The 3D printing head and the spray gun are coaxially linked to prepare a square light shield with a four-sided honeycomb structure on the inner wall, and the molding temperature is controlled. 420°C, speed of 25mm / s, extrusion rate of 120%, spraying flow rate of 8mL / h, and spraying angle of 35°. Under these conditions, the microcosmic surface is rough and evenly loaded with carbon black. High absorption and high mechanical stability A unique one-piece high-performance hood, which has an absorption rate of 98.21% under this condition, such as Figure 8 shown. In addition, the obtained light shield has high dimensional accuracy, which can meet the requirements for the use of geostationary orbit (GEO) remote sensing cameras.

example 3

[0057] Example 3: The organic base material is PEEK, the inorganic black paint is carbon black solution (30mg / mL) with ethanol as solvent, the molding temperature is controlled at 420°C, the speed is 25mm / s, the extrusion volume is 120%, and the spraying flow rate is 8mL / mL. h, the spraying angle is 35°, and under this condition, a light shield with an absorption rate of 97.15% is obtained, such as Figure 9 shown.

[0058] The invention adopts 3D printing technology and spraying technology to prepare the shading cover synchronously, rapid prototyping, good structural stability, high dimensional accuracy, firm combination of the shading cover and the inorganic black paint, and good shading performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com