3D printing preparation method of light shield for star sensor with high light absorption capacity

A star sensor, 3D printing technology, used in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve problems such as low dimensional accuracy, difficult machining, and damage to vibration tests, and achieve good physical strength, size and thickness. Highly controllable, lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

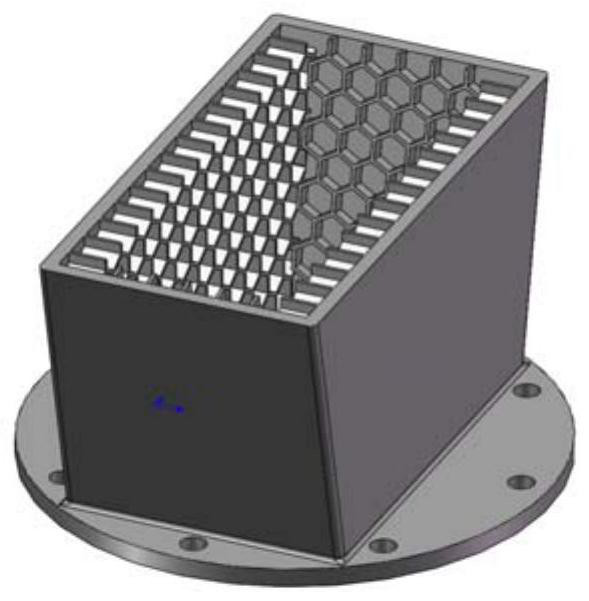

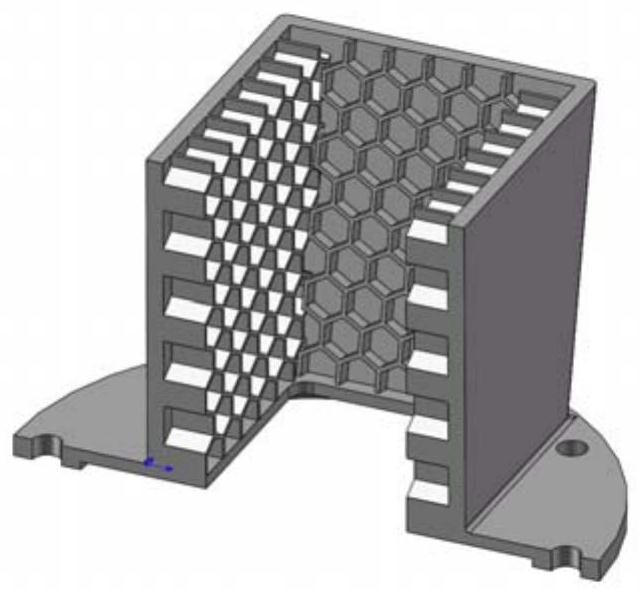

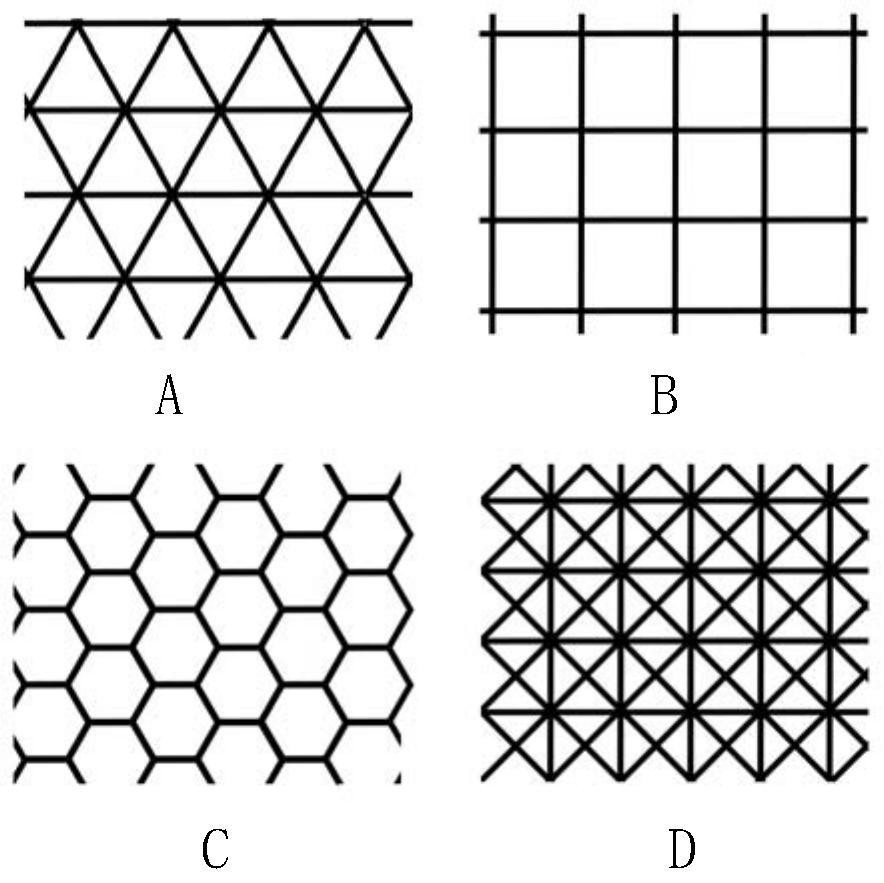

[0035] Such as Figure 1-Figure 3 As shown, the 3D printing preparation method of the light shield for the star sensor with high light absorption capacity comprises the following steps:

[0036] Step 1. Add the natural color high-performance polymer matrix material and carbon black into the extruder and mix fully to achieve coloring of the natural color high-performance polymer matrix material, wherein the mass of carbon black accounts for the natural color high-performance polymer matrix material and 0.5%-1.0% of the total mass of carbon black, the high-performance polymer matrix material is polyetheretherketone PEEK, polyetherimide PEI or polyvinylidene fluoride PVDF, and an extruder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com