Quaternary refractory high-entropy alloy coating resistant to high-temperature oxidation and laser cladding preparation method thereof

A technology of high-temperature oxidation resistance and laser cladding, which is applied in the direction of metal material coating technology, coating, metal processing equipment, etc., can solve the problems of difficult application scenarios, high brittleness of metal ceramics, and poor oxidation resistance, etc., to achieve high Stable preparation process characteristics, uniform particle size, and rapid preparation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

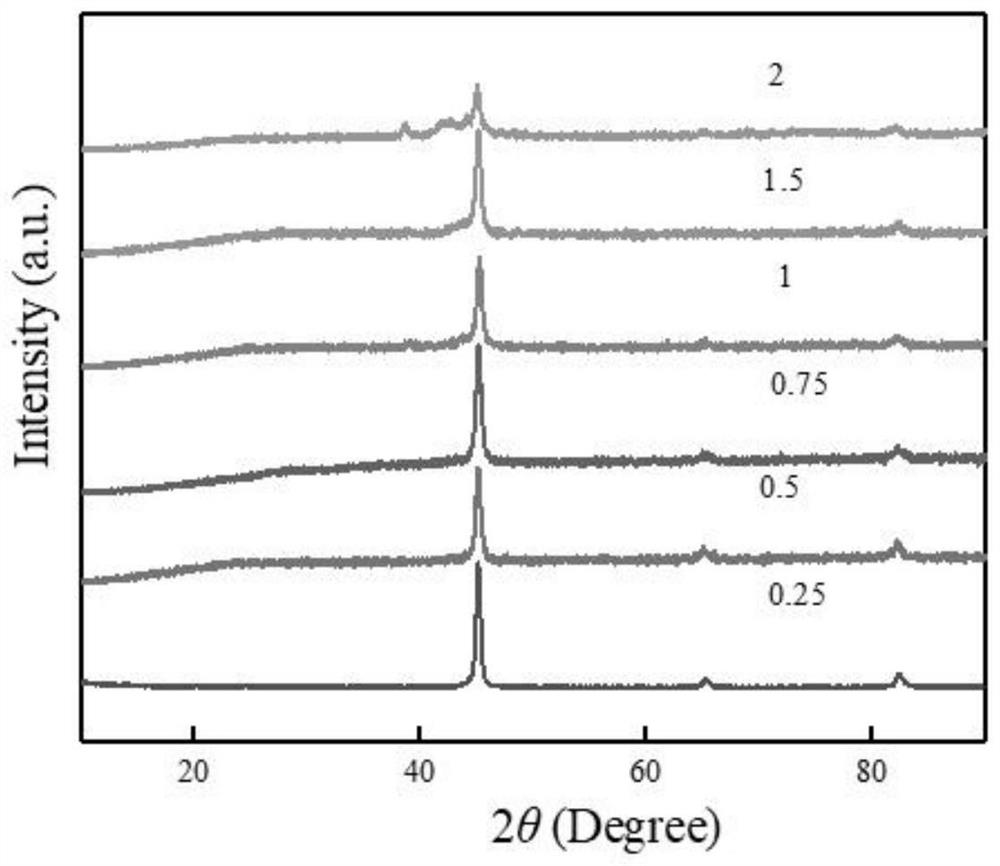

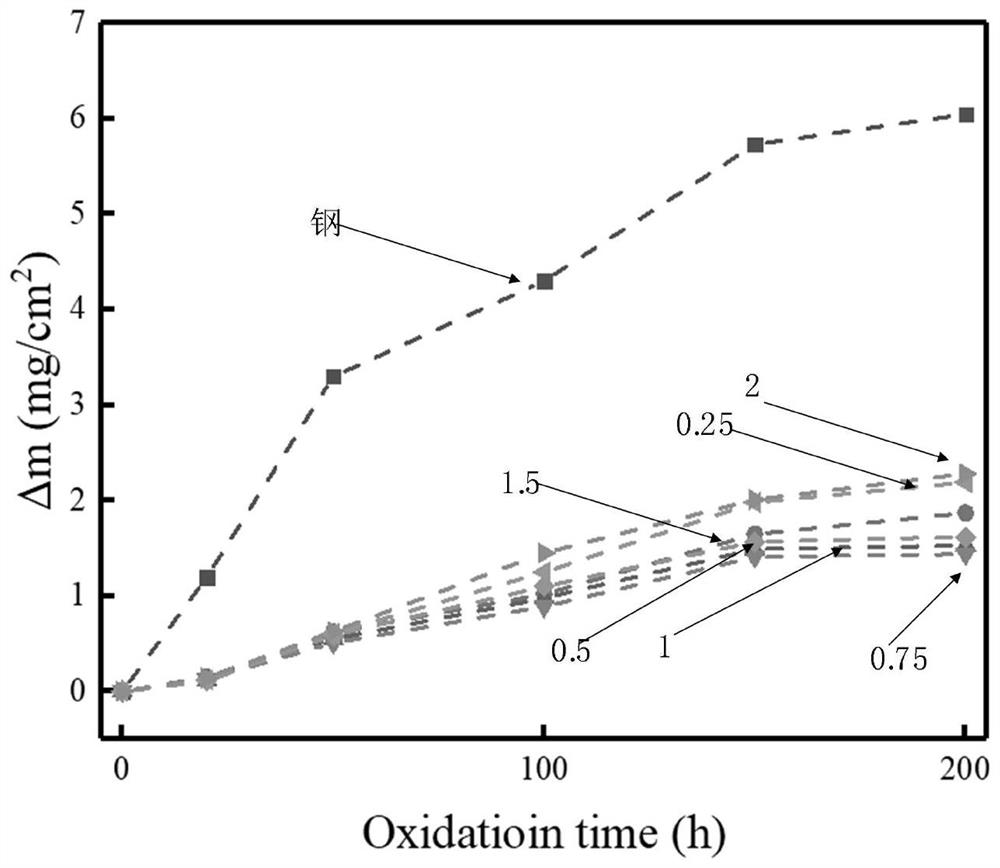

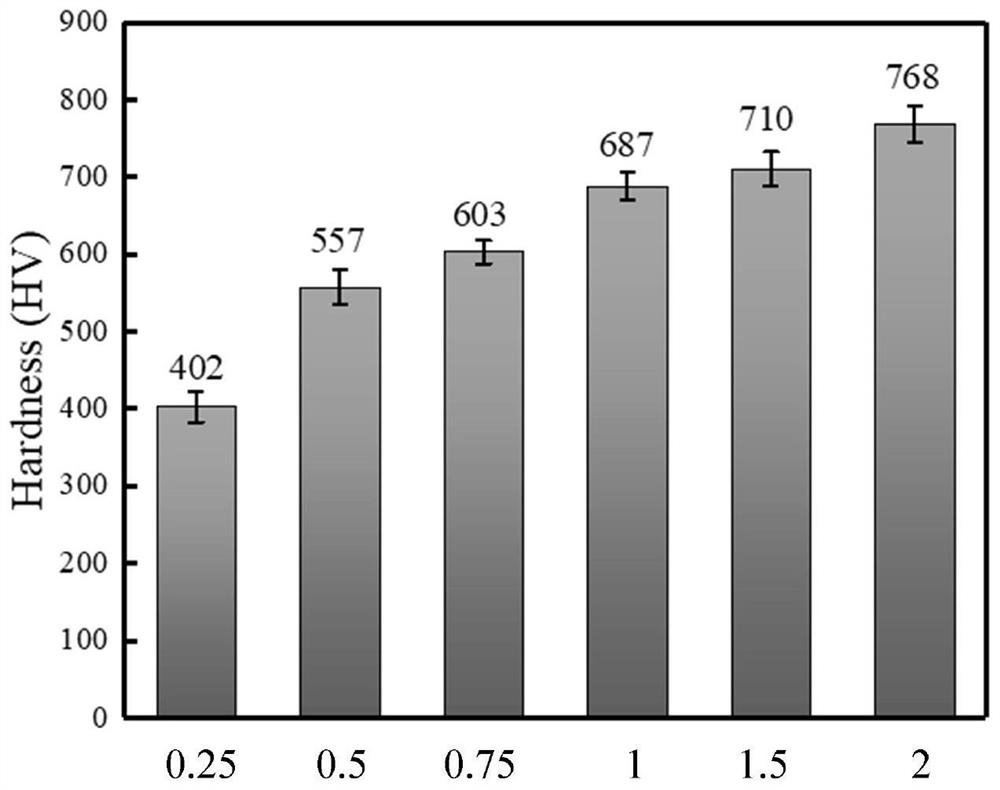

[0029] Embodiment 1: The laser cladding preparation method of the high-temperature oxidation-resistant quaternary refractory high-entropy alloy coating in this embodiment is achieved by the following steps:

[0030] Step 1. Weigh 10g of quaternary FeCrAlWx refractory high-entropy alloy powder, and on the surface of pre-coated steel with a size of 4cm*5cm*3cm, the ratio of high-entropy alloy powder mass to coating area is 1g: 2cm 2 , the thickness of pre-laid powder is 5mm; the height of steel is 10cm;

[0031] Step 2. Through the laser cladding technology, with a laser power of 2200W, a rate of 7cm / s, a spot diameter of 3mm, and a lap spacing of 1.5mm, an anti-high temperature oxidation quaternary refractory high-entropy alloy coating was constructed in situ on the steel surface. layer, where x=0.25.

[0032] In this embodiment, the quaternary FeCrAlWx refractory high-entropy alloy powder is prepared according to the following steps: weigh 41.38% iron, 38.38% chromium, 19.99%...

Embodiment 2

[0033] Embodiment 2: The laser cladding preparation method of the high-temperature oxidation-resistant quaternary refractory high-entropy alloy coating in this embodiment is achieved by the following steps:

[0034] Step 1. Weigh 10g of quaternary FeCrAlWx refractory high-entropy alloy powder, and on the surface of pre-coated steel with a size of 4cm*5cm*3cm, the ratio of high-entropy alloy powder mass to coating area is 1g: 2cm 2 , the thickness of pre-laid powder is 5mm; the height of steel is 10cm;

[0035] Step 2. Through the laser cladding technology, with a laser power of 2200W, a rate of 7cm / s, a spot diameter of 3mm, and a lap spacing of 1.5mm, an anti-high temperature oxidation quaternary refractory high-entropy alloy coating was constructed in situ on the steel surface. layer, where x=0.5.

[0036] In this embodiment, the quaternary FeCrAlWx refractory high-entropy alloy powder is prepared according to the following steps: weigh 41.27% iron, 38.33% chromium, 19.9% ...

Embodiment 3

[0037] Embodiment 3: The laser cladding preparation method of the high-temperature oxidation-resistant quaternary refractory high-entropy alloy coating in this embodiment is achieved by the following steps:

[0038] Step 1. Weigh 10g of quaternary FeCrAlWx refractory high-entropy alloy powder, and on the surface of pre-coated steel with a size of 4cm*5cm*3cm, the ratio of high-entropy alloy powder mass to coating area is 1g: 2cm 2 , the thickness of pre-laid powder is 5mm; the height of steel is 10cm;

[0039]Step 2. Through the laser cladding technology, with a laser power of 2200W, a rate of 7cm / s, a spot diameter of 3mm, and a lap spacing of 1.5mm, an anti-high temperature oxidation quaternary refractory high-entropy alloy coating was constructed in situ on the steel surface. layer, where x=0.75.

[0040] In this embodiment, the quaternary FeCrAlWx refractory high-entropy alloy powder is prepared according to the following steps: weigh 41.17% iron, 38.23% chromium, 19.85% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com