Preparation method of gold-graphene composite nano material

A graphene composite and nano-material technology, applied in the field of nano-materials, can solve the problems of no 2D peak, easy to fall off, easy to deform, etc., and achieve the effects of enhanced stability, strong controllability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation method of gold graphene composite nanomaterial comprises the steps:

[0017] (1) Mix 29 mL of HAuCl with a concentration of 10 mg / mL 4 The solution was added into 80mL methanol and ultrasonically treated for 1-2h to obtain solution A; 1g SiO 2 Add another 80mL of methanol to ultrasonic treatment for 1-2h to obtain solution B; mix solution A and solution B and then conduct ultrasonic treatment for 1-2h to remove methanol, and dry the obtained mixture at 75-85°C; The ultrasonic treatment mentioned in (1) refers to the ultrasonic treatment under the condition of 180w;

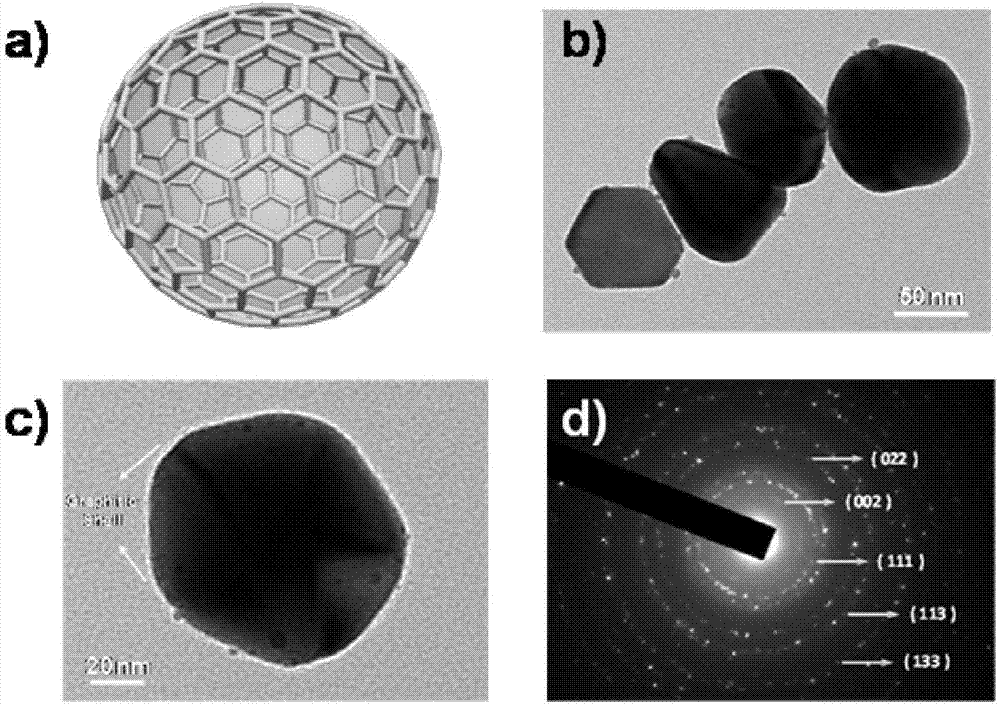

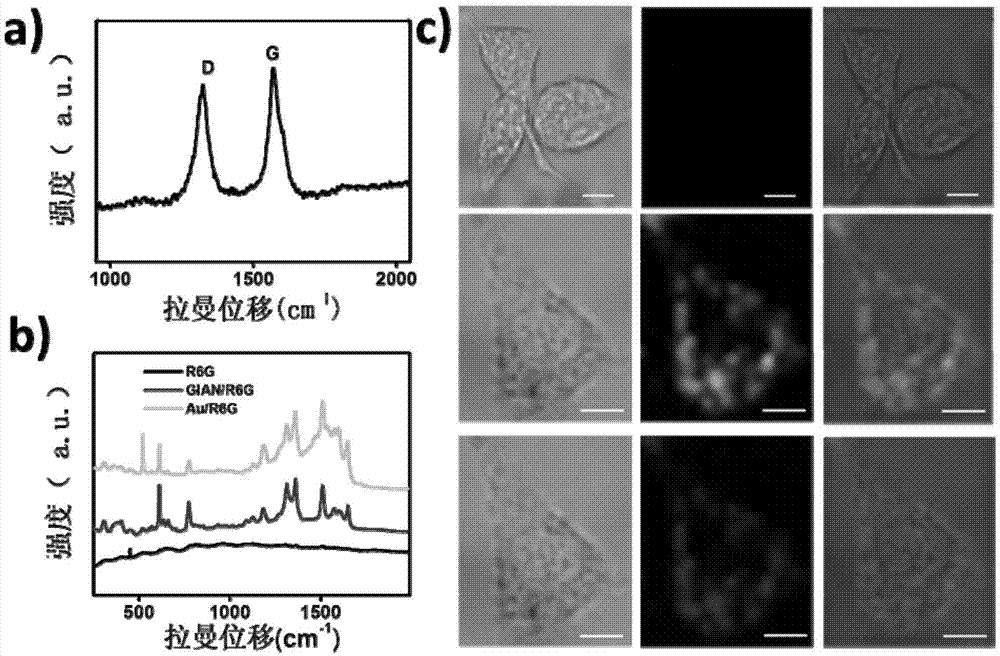

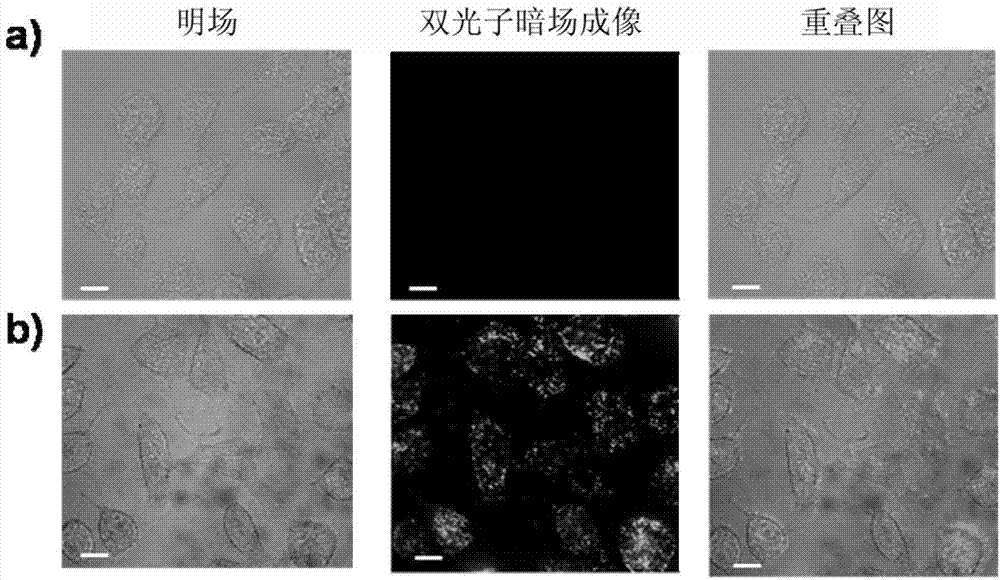

[0018] (2) Grind the mixture obtained in step (1) into powder in CH 4 The flow rate is 150cm 2 Ignite for 8-12min under the airflow condition of / mL, the burning temperature is 800-1000℃, mix with the mixed solution of HF, ethanol and water after cooling, centrifuge at 1000rpm for 3min, and obtain gold graphene after separating the centrifugal liquid Composite nanoparticles, (gold graphe...

Embodiment 2

[0020] The preparation method of gold graphene composite nanomaterial comprises the steps:

[0021] (1) Mix 29 mL of HAuCl with a concentration of 10 mg / mL 4 The solution was added into 80mL methanol and ultrasonically treated for 1-2h to obtain solution A; 1g SiO 2 Add another 80mL of methanol to ultrasonic treatment for 1-2h to obtain solution B; mix solution A and solution B and then conduct ultrasonic treatment for 1-2h to remove methanol, and dry the obtained mixture at 75-85°C; The ultrasonic treatment mentioned in (1) refers to the ultrasonic treatment under the condition of 180w;

[0022] (2) Grind the mixture obtained in step (1) into powder in CH 4 The flow rate is 180cm 2 Ignite for 8-12min under the airflow condition of / mL, the burning temperature is 800-1000℃, mix with the mixed solution of HF, ethanol and water after cooling, centrifuge at 1000rpm for 3min, and obtain gold graphene after separating the centrifugal liquid Composite nanoparticles (obtained by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com