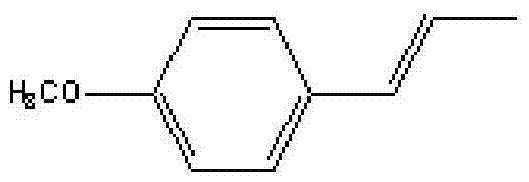

Method for synthesizing anethole by taking estragole oil as raw material

A technology of wormwood and anethole, applied in the field of synthesizing anethole, can solve the problems of low comprehensive utilization rate of anise oil, and achieve the effects of realizing reuse value, simple method and improving comprehensive utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Mix 6gKOH and 3gNaOH to prepare KOH / NaOH basic catalyst. Add the prepared catalyst into a stainless steel conical flask containing 120 g of wormwood oil (78.2% wormwood GC content), stir and reflux to rapidly raise the temperature to about 210°C, and continue the reaction for 2.5 hours. After the reaction is completed, cool to 70°C, add hot water to wash twice, let stand to separate layers, put the obtained oil layer in the refrigerator, and freeze and crystallize at 2°C, the crystallization time is 20h. The obtained crystals were crushed and separated using a centrifuge to obtain 75.7 g of anethole crude product.

[0021] The obtained crude anethole product was subjected to rectification and separation under the condition of vacuum degree of 99.4KPa and reflux ratio of 6:1, and the fraction between 123°C was collected to obtain 68.4g of the final product. 99.6%, of which trans-anethole content is 96.9%.

Embodiment 2

[0023] Take 10g KOH and 15g polyethylene glycol 1000 in a stainless steel flask, use an electric heating mantle to heat until completely melted and raise the temperature to 210°C, then add 154g wormwood oil (78.2% wormhole GC content) dropwise to the flask, reflux and The reaction was stirred for about 1.5h. After the reaction is completed, cool to 60°C, add hot water to wash twice, let stand to separate layers, put the obtained oil layer in the refrigerator, and refrigerate and crystallize at 2°C for 20 hours. The obtained crystals were crushed by adding 100 ml of ice-cold brine at -5°C, and separated using a centrifuge to obtain 115.1 g of anethole crude product.

[0024] The obtained crude anethole product was subjected to rectification and separation under the conditions of vacuum degree of 99.8KPa and reflux ratio of 7:1, and the fraction between 124°C was collected to obtain 104.4g of the final product, the relative effective yield of anethole was 86.7%, and the content ...

Embodiment 3

[0026] Take 10g of KOH and 100020g of polyethylene glycol in a three-necked stainless steel flask, heat it with an electric heating mantle until it is completely melted and raise the temperature to 150°C, then add 154g of wormwood oil (78.2% wormwood GC content) dropwise into the flask, reflux and The reaction was stirred for 1h. After completion of the reaction, cool to 80°C, add hot water to wash twice, stand to separate layers, put the obtained oil layer in the refrigerator, and refrigerate and crystallize at 2°C for 24 hours. The obtained crystals were crushed by adding 100 ml of ice-cold brine at -5°C, and separated by a centrifuge to obtain 106.8 g of anethole crude product.

[0027] The obtained crude anethole product was subjected to rectification and separation under the conditions of vacuum degree of 99.4KPa and reflux ratio of 6:1, and the fraction between 120°C was collected to obtain 97.8g of the final product, with a relative effective yield of 83.6% of anethole....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com