Engineering plastic applicable to LDS (Laser Direct Structuring) forming process as well as preparation method and application thereof

A technology for engineering plastics and molding process, applied in the field of engineering plastics and their preparation, can solve the problems of poor laser inducibility and physical and mechanical properties of engineering plastics, achieve good laser inducibility and mechanical properties, reduce processing procedures, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Correspondingly, the embodiment of the present invention also provides a preparation method of the engineering plastics suitable for the LDS molding process, the method includes the following steps:

[0038] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned nitrile rubber / EPDM rubber aging-resistant material. The method comprises the steps of:

[0039] S01. Weigh the formula components: Weigh each component according to the component content of the engineering plastics suitable for the LDS molding process described above;

[0040] S02. Melting and extruding after mixing each component: performing mixing and extruding each component weighed in step S01.

[0041]Specifically, the components of the engineering plastics suitable for the LDS molding process in the above-mentioned step S01 and the preferred content and type of each component are as described above, wherein the preparation method of the laser-ac...

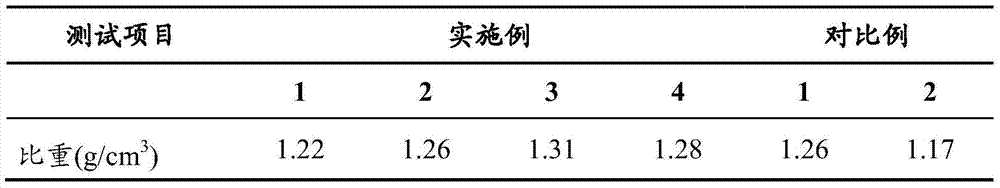

Embodiment 1

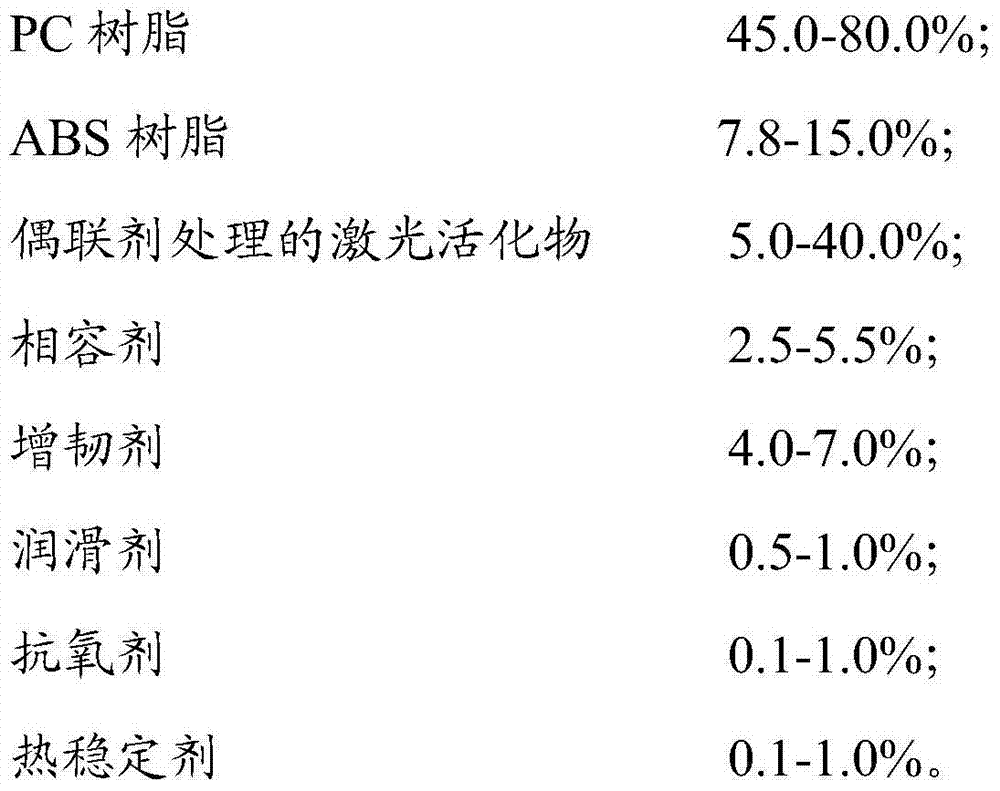

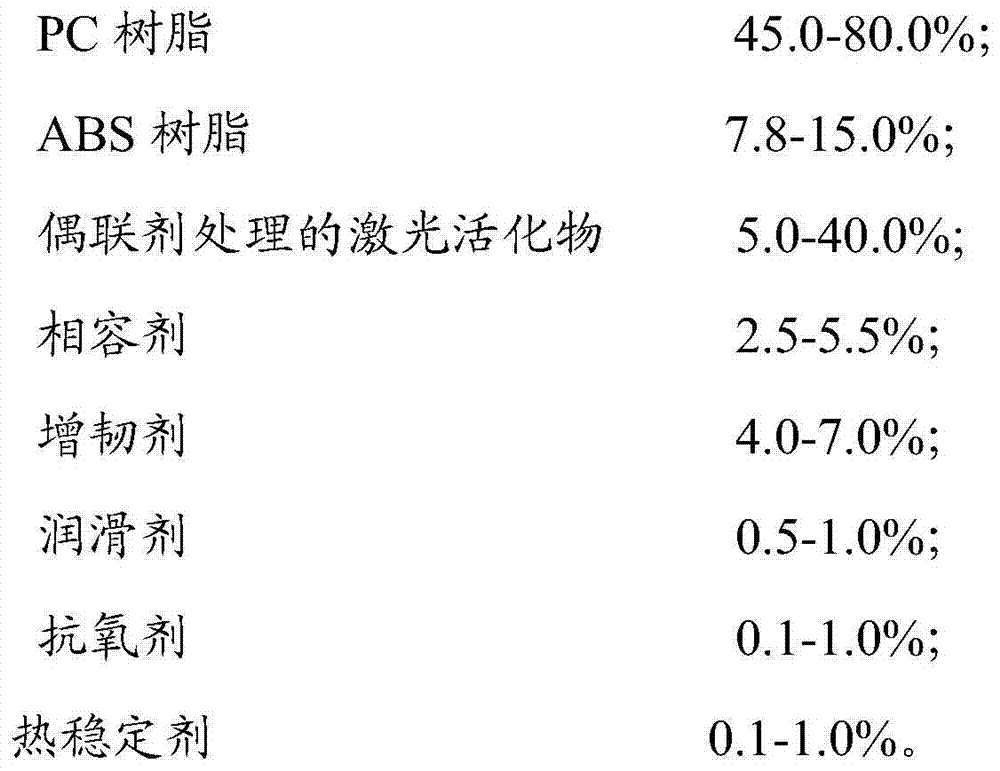

[0049] Engineering plastics suitable for LDS molding process and preparation method thereof. Wherein, the engineering plastics suitable for the LDS molding process contains the following components:

[0050] PC70.0%, ABS15.8%, coupling agent-treated laser activator 5.0%, compatibilizer 3.0%, toughening agent 5.0%, lubricant 0.5%, antioxidant 0.4%, heat stabilizer 0.3%. Among them, the coupling agent in the laser activator treated by the coupling agent is γ-aminopropyltriethoxysilane, and the laser activator is AB 2 o 4 ; The compatibilizer is ABS grafted maleic anhydride ABS-g-MAH, the toughening agent is toughening agent E518, the lubricant is EBS120, and the antioxidant is tetrakis[3-(3,5-di-tert-butyl-4 -Hydroxyphenyl)propionic acid]pentaerythritol ester and tris(2,4-di-tert-butylphenyl phosphite) in a weight ratio of 1:1, and the heat stabilizer is an organic copper composite heat stabilizer.

[0051] Its preparation method:

[0052] Preparation of laser-activated mate...

Embodiment 2

[0055] Engineering plastics suitable for LDS molding process and preparation method thereof. Among them, the engineering plastic suitable for LDS molding process contains the following components:

[0056] PC55.0%, ABS15.8%, coupling agent treated laser activator 20.0%, compatibilizer 3.0%, toughening agent 5.0%, lubricant 0.5%, antioxidant 0.4%, heat stabilizer 0.3%.

[0057] Among them, the coupling agent in the laser activator treated by the coupling agent is γ-methacryloxypropyl trimethoxysilane, and the laser activator is AB 2 o 4 ; The compatibilizer is SMA, the toughening agent is toughening agent E518, the lubricant is EBS120, and the antioxidant is triethylene glycol bis-3-(3-tert-butyl-4-hydroxy-5-methylphenyl) Acrylonitrile, the heat stabilizer is an organotin heat stabilizer.

[0058] Its preparation method:

[0059] Preparation of laser-activated material treated with coupling agent: dry the laser-activated material at 100°C for 3 hours and then place it in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com