Single-component moldproof transparent dealcoholized silicone sealant and preparation method thereof

A silicone sealant and dealcoholization technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of yellowing and mildew of silicone sealant, improve thixotropy and improve compatibility , Overcome the effect of slow curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

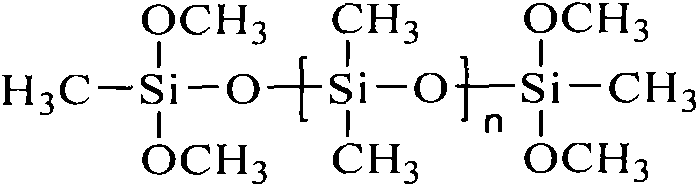

[0028] Add 100 parts of glue with a kinematic viscosity of 20 Pa·s107 into the mixer, use 1.6 parts of methyltrimethoxysilane under the conditions of nitrogen gas and temperature of 60 ° C, and carry out capping reaction for 60 minutes to obtain 100 parts of terminal methyl dimethoxy base polydimethylsiloxane; adding 100 parts of methyl-terminated polydimethylsiloxane with kinematic viscosity of 5Pa·s and 15 parts of hydrophobic fumed silica with a specific surface area of 150m2 / g in vacuum > Stir for 25 minutes under the condition of 0.09Mpa; finally add 8 parts of methyltrimethoxysilane, 0.8 parts of 10,10-oxobisphenoxarsenic with polyether polyol as carrier, 3 parts of γ-aminopropyltrimethoxysilane 1 part, 0.4 part of dibutyl tin dilaurate, and stirred for 10 minutes under the condition of vacuum degree >0.09Mpa to make a one-component anti-mold transparent dealcoholized silicone sealant. The product performance test results are shown in Table 1.

Embodiment 2

[0030] Add 100 parts of 107 glue with a kinematic viscosity of 20 Pa·s into the mixer, and use 2 parts of methyltrimethoxysilane to carry out capping reaction for 60 minutes under nitrogen gas and temperature of 60 ° C to obtain 100 parts of terminal methyl dimethyl Oxygenated polydimethylsiloxane; adding 50 parts of polydimethylsiloxane with a kinematic viscosity of 2Pa·s and a specific surface area of 150m 2 / g 25 parts of hydrophobic fumed silica and stirred for 25 minutes under the condition of vacuum degree >0.09Mpa; finally, 5 parts of vinyltrimethoxysilane and 10,10-oxobisphenoxane with polyether polyol as the carrier were added 1.5 parts of arsenic, 3 parts of N-β-aminoethyl γ-aminopropyl trimethoxysilane, 0.4 parts of dioctyltin dilaurate, stirred for 10 minutes under the condition of vacuum>0.09Mpa to make a one-component anti-mold transparent Dealcoholized silicone sealant, product performance test results are shown in Table 1.

Embodiment 3

[0032] Add 100 parts of 107 glue with a kinematic viscosity of 20 Pa·s into the mixer, and use 2 parts of methyltrimethoxysilane to carry out capping reaction for 60 minutes under nitrogen gas and temperature of 60 ° C to obtain 100 parts of terminal methyl dimethyl Oxygenated polydimethylsiloxane; add 20 parts of methyl-terminated polydimethylsiloxane with kinematic viscosity of 0.3Pa·s, specific surface area of 200m2 / g hydrophobic fumed silica Stir for 25 minutes under the condition of 0.09Mpa; finally add 5 parts of phenyltrimethoxysilane, 0.3 parts of 10,10-oxobisphenoxarsenic with polyether polyol as carrier, N-methyl-3-aminopropyl 3 parts of trimethoxysilane and 0.4 parts of dibutyltin di(dodecylsulfide) were stirred for 10 minutes under the condition of vacuum degree>0.09Mpa to make a one-component anti-mold transparent dealcoholized silicone sealant, product performance test results See Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com