Aluminum alloy color-coated sheet and strip and production method thereof

A production method and technology for color-coated sheets, applied in the field of aluminum alloy manufacturing, can solve the problems of low full-hard formability, complex processing flow, increased thickness, etc., so as to save the intermediate annealing process, ensure mechanical properties, and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

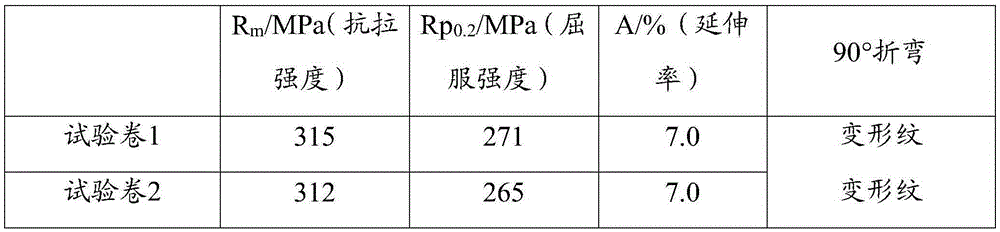

Embodiment 1

[0024] In this embodiment, an aluminum alloy color-coated sheet and strip (AA01 alloy color-coated aluminum sheet), the mass percentage of its chemical composition is (single ≤ 0.05% of other impurity elements (such as Zn), and the total of other impurity elements ≤ 0.15%):

[0025] Si

Fe

Cu

mn

Mg

Ti

Cr

Zn

Al

0.13

0.38

0.15

0.88

1.6

0.02

0.03

0.02

margin

[0026] The production process of the aluminum alloy color-coated sheet and strip described in this embodiment includes: melting and casting→sawing→face milling→heating→hot continuous rolling→cold continuous rolling→edge trimming→leveling→coating. The specific process parameters are as follows:

[0027] (1) Melting and casting: the mass percentage of the chemical composition of the ingot after melting and casting is (single ≤0.05% of other impurity elements, ≤0.15% of other impurity elements in total):

[0028] Si

Fe

Cu

...

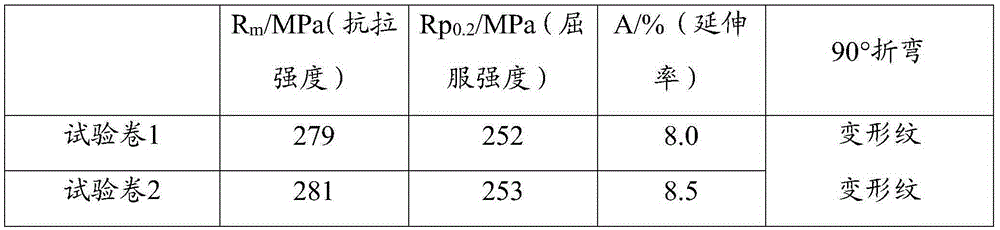

Embodiment 2

[0039] In this embodiment, an aluminum alloy color-coated sheet and strip (AA01 alloy color-coated aluminum sheet), the mass percentage of its chemical composition is (single ≤ 0.05% of other impurity elements, ≤ 0.15% in total of other impurity elements):

[0040] Si

Fe

Cu

mn

Mg

Ti

Cr

Zn

Al

0.15

0.31

0.20

0.62

2.05

0.02

0.03

0.02

margin

[0041] The production process of the aluminum alloy color-coated sheet and strip described in this embodiment includes: melting and casting→sawing→face milling→heating→hot continuous rolling→cold continuous rolling→edge trimming→leveling→coating. The specific process parameters are as follows:

[0042] (1) Melting and casting: the mass percentage of the chemical composition of the ingot after melting and casting is (single ≤0.05% of other impurity elements, ≤0.15% of other impurity elements in total):

[0043] Si

Fe

Cu

mn

Mg

T...

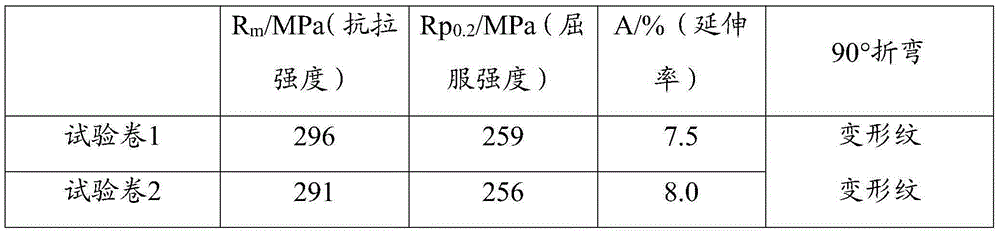

Embodiment 3

[0054] In this embodiment, an aluminum alloy color-coated sheet and strip (AA01 alloy color-coated aluminum sheet), the mass percentage of its chemical composition is (single ≤ 0.05% of other impurity elements, ≤ 0.15% in total of other impurity elements):

[0055] Si

Fe

Cu

mn

Mg

Ti

Cr

Zn

Al

0.13

0.44

0.12

0.78

1.73

0.02

0.03

0.02

margin

[0056] The production method of the roof panel aluminum alloy sheet and strip described in this embodiment includes: melting and casting→sawing→milling→heating→hot continuous rolling→cold continuous rolling→edge trimming→levelling→coating. The specific process parameters are as follows:

[0057] (2) Melting and casting: the mass percentage of the chemical composition of the ingot after melting and casting is (single ≤0.05% of other impurity elements, ≤0.15% of other impurity elements in total):

[0058] Si

Fe

Cu

mn

Mg

Ti

Cr ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com