Wheel set and gear case cleaning agent for high-speed rails and use method thereof

A cleaning agent and gearbox technology, which is applied in the field of high-speed rail maintenance, cleaning and protection, can solve problems such as environmental pollution and health hazards, and achieve the effects of solving environmental pollution, saving costs, and enhancing cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

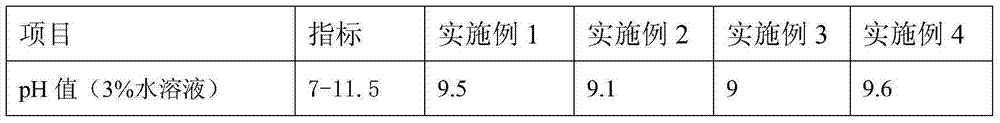

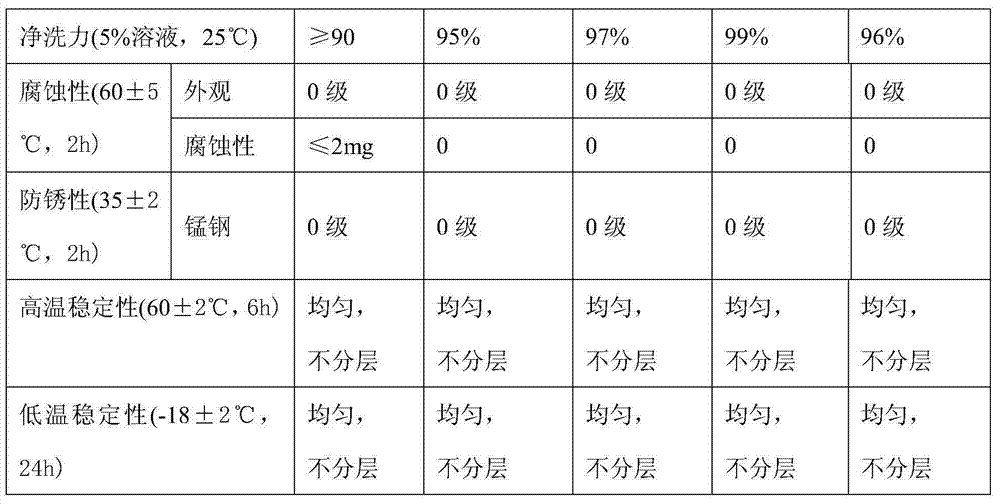

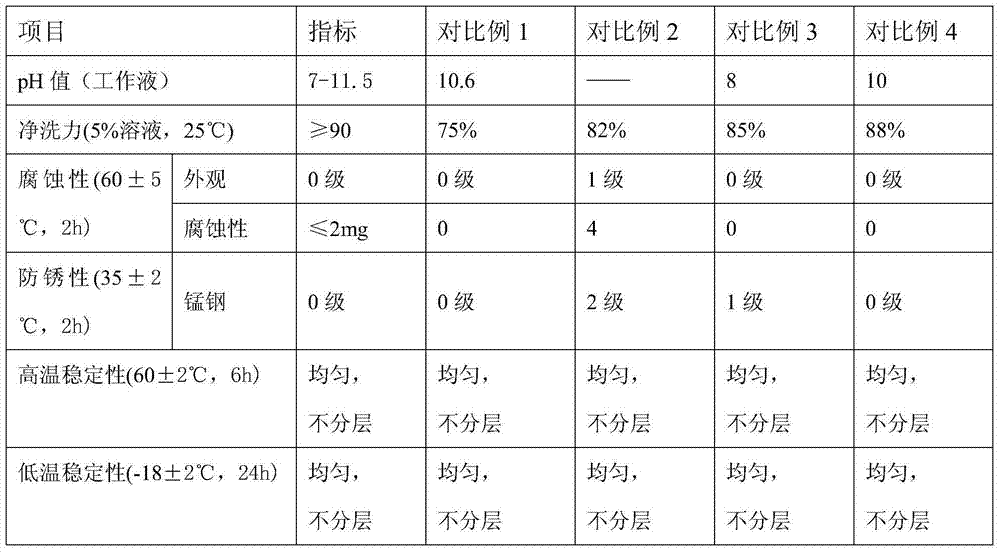

Examples

Embodiment 1

[0017] 1. Test material: high-speed rail wheel set during maintenance.

[0018] 2. Cleaning agent formula: 100g of cleaning agent includes 4g of triethanolamine, 2g of dodecyl dicarboxylic acid, 4g of isomeric alcohol polyoxyethylene ether, 1g of EDTA·2Na, 1g of 2-sodium acrylate homopolymer, and the balance is water .

[0019] 3. Preparation of working solution: Pour the above cleaning agent into the container and dilute it by 10-20 times.

[0020] 4. Cleaning method: Use the working fluid prepared in the container to directly spray the wheel set with a high-pressure spray gun.

Embodiment 2

[0022] 1. Test material: high-speed rail wheel set during maintenance.

[0023] 2. Cleaning agent formula: 100g of cleaning agent includes 5g of triethanolamine, 2g of dodecane dicarboxylic acid, 5g of isomeric alcohol polyoxyethylene ether, 3g of EDTA·2Na, 2g of polyacrylic acid, and the balance is water.

[0024] 3. Preparation of working solution: Pour the above cleaning agent into the container and dilute it by 10-20 times.

[0025] 4. Cleaning method: Use the working fluid prepared in the container to directly spray the wheel set with a high-pressure spray gun.

Embodiment 3

[0027] 1. Test material: high-speed rail wheel set during maintenance.

[0028] 2. Cleaning agent formula: 100g of cleaning agent includes 5g of triethanolamine, 3g of dodecane dicarboxylic acid, 3g of isomeric alcohol polyoxyethylene ether, 1g of NTA, 2g of sodium acrylate homopolymer, and the balance is water.

[0029] 3. Preparation of working solution: Pour the above cleaning agent into the container and dilute it by 10-20 times.

[0030] 4. Cleaning method: Use the working fluid prepared in the container to directly spray the wheel set with a high-pressure spray gun.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com