A new drawing method in the preparation process of polyacrylonitrile-based carbon fiber precursor

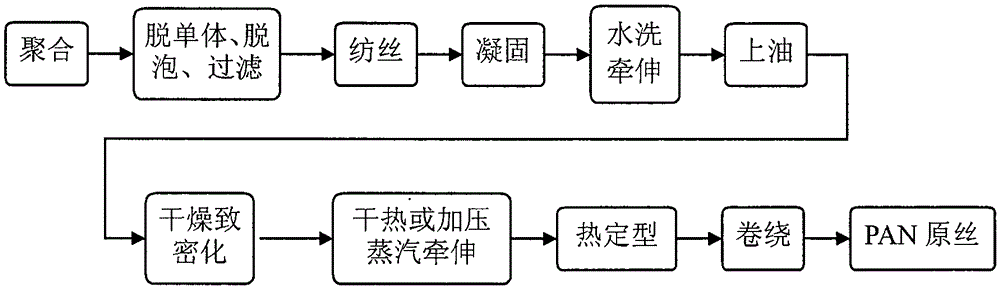

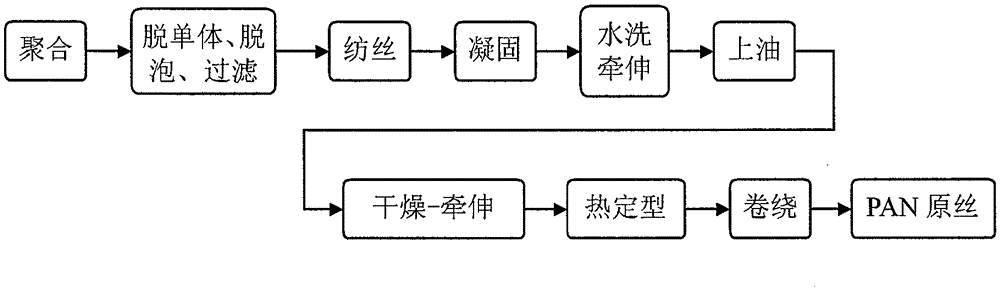

A polyacrylonitrile-based carbon fiber, a preparation process technology, applied in the direction of stretch spinning, filament generation, artificial filament cleaning/drying, etc., can solve the limited application, poor operability, pressurized steam drafting device structure Complexity and other issues, to achieve the effect of simplifying the process, good performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: one-step drying drafting 1KPAN base carbon fiber precursor

[0023] After coagulation-water washing-hot water drawing-oiling process, the 1K PAN-based carbon fiber precursor is rolled by rollers so that the moisture content in the tow is 30%; the tow is spread to make the thickness 0.10 mm; then It goes into a hot box for drying-drawing. The hot box temperature was set at 140°C and the residence time in the hot box was 3 seconds. The fiber precursors can be drawn up to 3.5 times. Then enter the subsequent heat setting process, and then wind up to obtain the PAN-based carbon fiber precursor. The tensile strength of each single filament in the fiber bundle is measured to be about 55-60 cN / dtex, and the elongation at break is about 10-16%.

Embodiment 2

[0024] Embodiment 2: one-step drying drafting 1KPAN base carbon fiber precursor

[0025] After coagulation-water washing-hot water drawing-oiling process, the 1K PAN-based carbon fiber precursor is rolled by rollers so that the moisture content in the tow is 25%; the tow is spread to make the thickness 0.15 mm; then It goes into a hot box for drying-drawing. The hot box temperature was set at 160°C and the residence time in the hot box was 3 seconds. The fiber precursors can be drawn up to 5.5 times. Then enter the subsequent heat setting process, and then wind up to obtain the PAN-based carbon fiber precursor. The tensile strength of each single filament in the fiber bundle is measured to be about 55-75 cN / dtex, and the elongation at break is about 8-12%.

Embodiment 3

[0026] Embodiment 3: one-step drying drafting 3KPAN base carbon fiber precursor

[0027] After coagulation-water washing-hot water drawing-oiling process, the 3K PAN-based carbon fiber precursor is rolled by rollers so that the moisture content in the tow is 35%; the tow is spread to make the thickness 0.10 mm; then It goes into a hot box for drying-drawing. The hot box temperature was set at 150°C and the residence time in the hot box was 4 seconds. The fiber precursors can be drawn up to 4.5 times. Then enter the subsequent heat setting process, and then wind up to obtain the PAN-based carbon fiber precursor. The tensile strength of each single filament in the fiber bundle is measured to be about 55-75 cN / dtex, and the elongation at break is about 8-12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com