Double-face simultaneous difference coating process method for polyimide film

A technology of polyimide film and process method, which is applied in the direction of pretreatment surface, device for coating liquid on surface, coating, etc., can solve the problems of difficult to balance and stable product quality, high content of operation technology, and many control links. , to achieve the effect of easy product quality, shortened process flow, and fewer control links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In conjunction with the accompanying drawings, the present invention is described in further detail below:

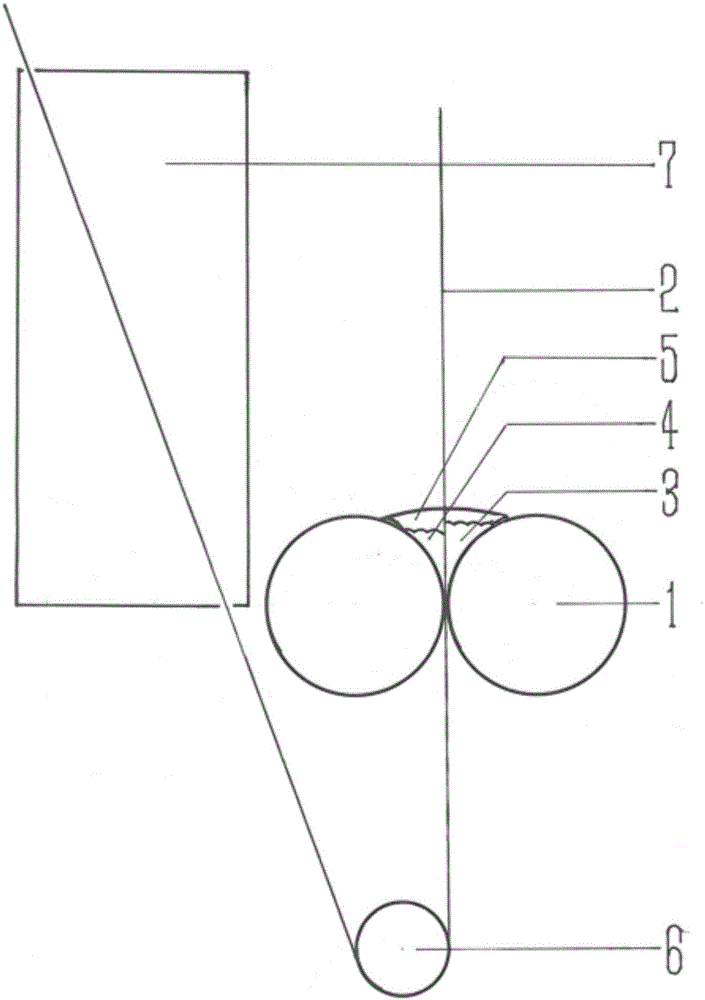

[0017] Such as figure 1 As shown, the present invention uses two equal-diameter, parallel, horizontally juxtaposed, adjustable distance between a pair of pressure rollers 1, the two ends of the upper angle are blocked by the rubber groove baffle plate 5, and the polyimide film 2 that passes vertically Divide in the middle to form thick glue groove 3 and thin glue groove 4, and set tangential turning roller 6 on the vertical line tangentially below the pressure roller 1 on the side of thin glue groove 4, and the polyimide film 2 after double-sided gluing After the turning roller 6 changes direction, it passes through the drying box 7 diagonally.

[0018] During production, the polyimide film 2 is threaded through the whole process of winding, and the concentration of the polyammonium ethylene propylene glue solution is adjusted according to the thickness ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com