Floor structure for raw bamboo structural system

A kind of original bamboo and system technology, applied in the direction of floors, building components, building structures, etc., can solve the problems of loose overall connection structure, lack of impermeability, weak overall tensile force, etc., to achieve simple structure, reduce seasonal or regional The effect of sexual restriction and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

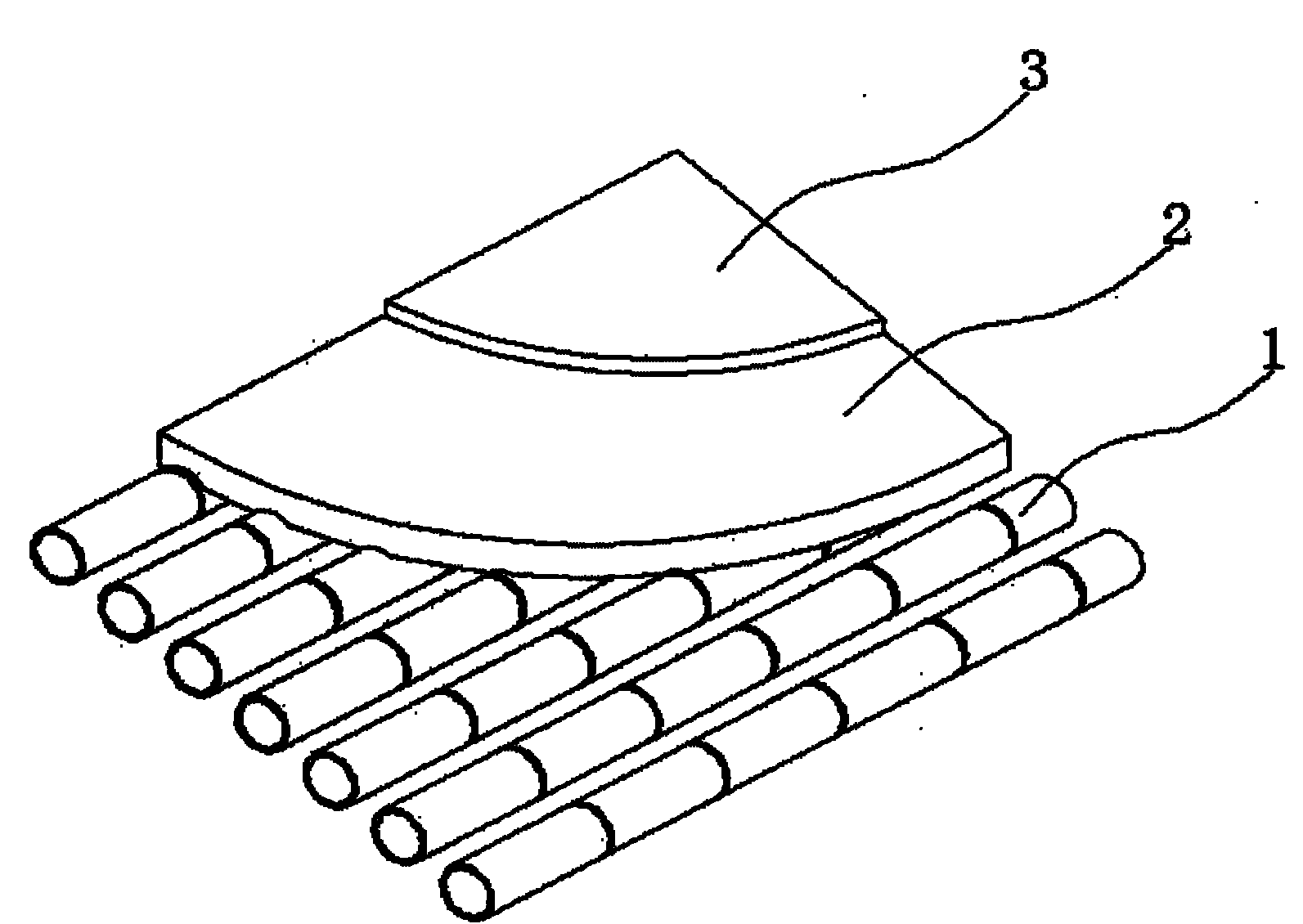

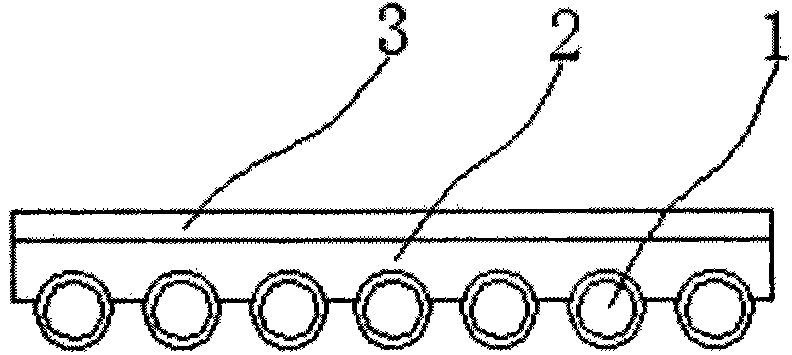

[0018] see Figure 1-2 , a floor structure for the original bamboo structure system, which includes the original bamboo floor beam 1, the original bamboo floor beam 1 is composed of original bamboos arranged side by side and fixed, and the original bamboo floor beam 1 is covered with a layer of thermal insulation material 2. The thermal insulation material 2 is covered with a layer of crack-resistant mortar 3; wherein, the raw bamboo is preferably made of raw bamboo with a diameter of 80-90mm; the thermal insulation material 2 is preferably made of a density grade of 200-600kg / m 3 Lightweight thermal insulation material, the strength after drying is greater than 0.25MPa, while significantly improving the load-bearing purpose of the floor, it greatly reduces the self-weight of the thermal insulation material 2; the anti-cracking mortar 3 is preferably made of fine mortar with a label above C15 For stone concrete, polypropylene fiber should be added during pouring, which can e...

Embodiment 2

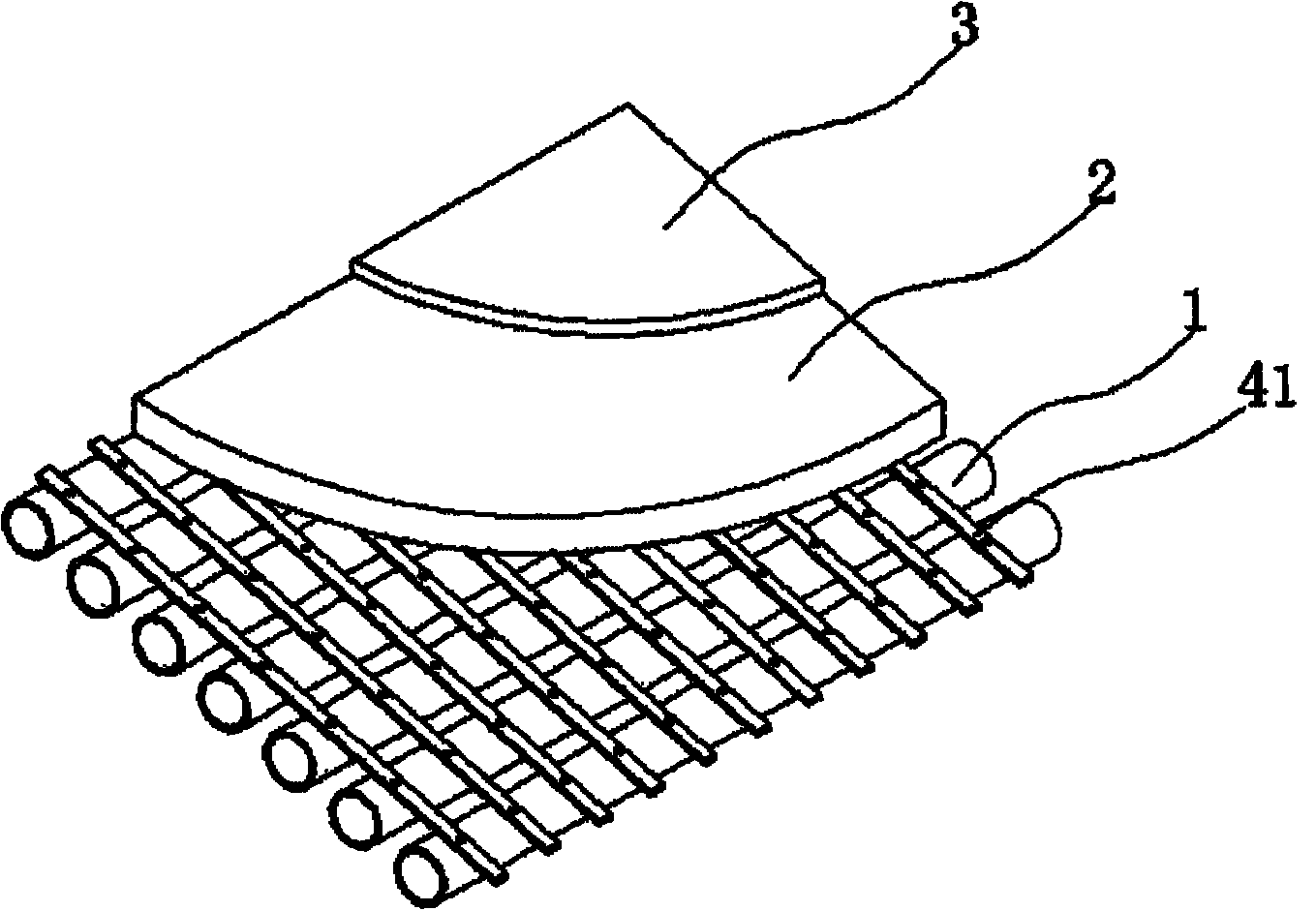

[0023] see Figure 3-4 , as an improvement to Example 1, preferably, the original bamboo floor beam 1 is covered with a layer of reinforcement layer 4, the reinforcement layer 4 is composed of bamboo strip layers 41 evenly arranged on the original bamboo floor beam 1, each independent The bamboo strips 41 are connected and fixed with the original bamboo by self-tapping screws, and the reinforcement layer 4 is covered with a layer of thermal insulation material 2, and the thermal insulation material 2 is covered with a layer of anti-crack mortar 3; wherein the original bamboo floor beam 1 is originally The spacing between the bamboos is 2-6cm.

[0024] In this embodiment, since the reinforcement layer 4 is added to the original bamboo floor beam 1, the spacing between the original bamboos in the original bamboo floor beam 1 can be relaxed, and the overall tensile force of the floor can be further improved, thereby improving the overall seismic performance.

Embodiment 3

[0026] see Figure 5-6 , as an improvement to Embodiment 1 and Embodiment 2, preferably, the whole of the original bamboo floor beam 1 is composed of two layers of original bamboo arranged side by side, and a reinforcement layer 4 is arranged between the two layers of original bamboo, so that The reinforcement layer 4 is composed of bamboo strips 41 evenly arranged between the original bamboos, each independent bamboo strip 41 is connected and fixed with the original bamboo by self-tapping screws, and a connecting piece 5 is connected between the two adjacent original bamboos up and down. .

[0027] Described connecting piece 5 comprises the annular stopper 51 that is attached to the original bamboo outer surface, and the middle part of this annular stopper 51 is provided with screw hole, and the bolt rod 52 that is inserted and matched with it is provided in this screw hole, and described bolt The other end of the rod 52 passes through the original bamboo on the upper floor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com