Insulation steel silo with parallel structure roof and manufacturing method thereof

A silo roof panel and silo technology, which is applied in thermal insulation, building components, building types, etc., can solve problems such as waste of manpower and material resources, and achieve the effects of improved wind resistance, reduced thickness, and reasonable load distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

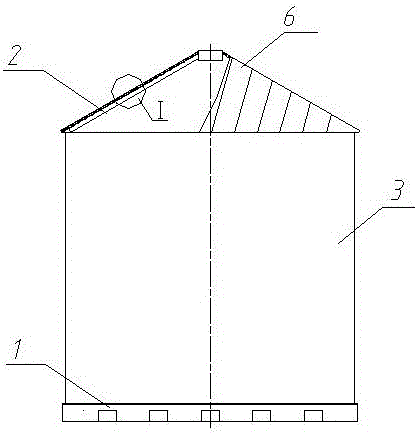

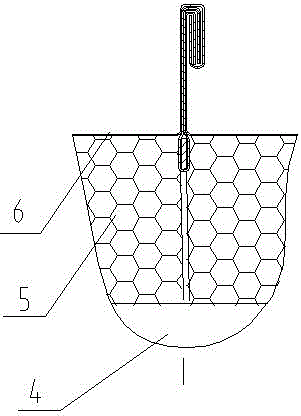

[0027] An insulating steel silo with a parallel structure roof, its composition includes: a foundation 1, a silo 3 installed on the foundation, the silo has an insulation layer 5, and the silo roof of the silo 2 includes frame 4 and top plate 6. The top of the silo is conical, or the bottom adopts the side of a truncated cone, and the top adopts a slightly raised central top surface. The roof main body is an equal-width continuous pavement structure.

Embodiment 2

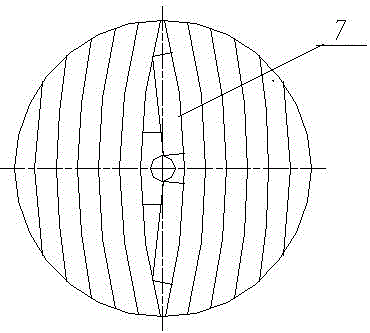

[0029] In the thermal insulation steel silo with a parallel structure roof described in Example 1, the olive-shaped central area 7 of the silo roof includes triangular, trapezoidal and strip-shaped pavement structures; the skeleton is a cone or a pyramid or The frame is in the form of a truncated cone, and the top plate is fixedly connected with the frame.

Embodiment 3

[0031] In the heat-insulating steel silo with a parallel structure roof described in Embodiment 1 or 2, after the silo roof is welded and formed, it is welded with the uppermost wall plate of the silo to form an overall airtight structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com