Gear-adjustable planetary gear train transmission

A technology of planetary gear train and planetary gear, which is applied in vehicle gearboxes, gear transmissions, components with teeth, etc., can solve the problems of small transmission ratio selectivity, large volume, small transmission ratio, etc., and achieve reliable The effects of selectivity, high transmission efficiency, and small power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

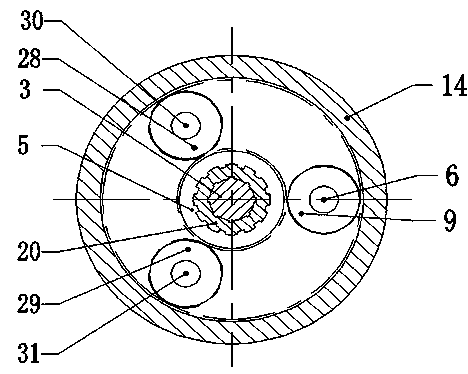

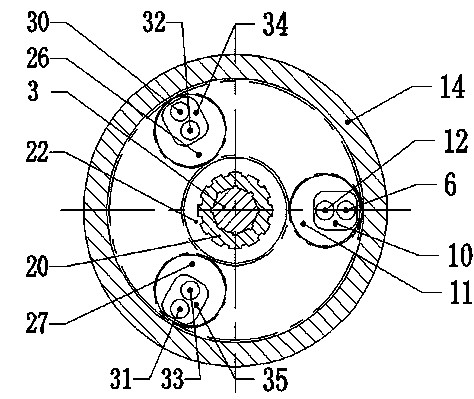

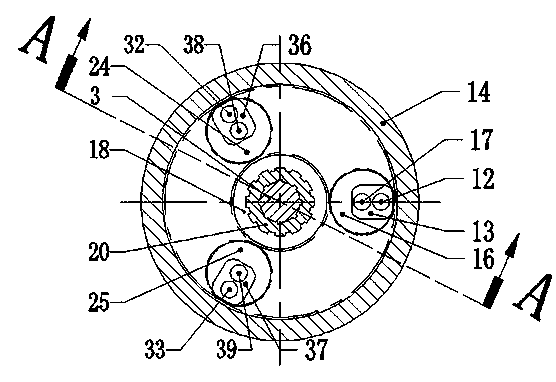

Embodiment 1

[0022] Embodiment 1: as Figure 1-6 As shown, a planetary gear train transmission with adjustable gears includes planetary gear system I, planetary gear system II, planetary gear system III, output shaft system, planet carrier fixed front end cover 1, planet carrier fixed rear end cover 21, Ring gear end cover 8, stepped ring gear 14; the output shaft system includes output shaft 3, sleeve 4, slidable sleeve 19, slidable spline 20, spring 23, deep groove ball bearing I2, deep groove Ball bearing Ⅱ7, deep groove ball bearing Ⅲ15, the outside of the output shaft 3 is stepped, and the largest part of the middle diameter of the output shaft 3 adopts the outer rectangular spline structure and the inner rectangular spline structure of the slidable spline 20, which can slide The outside of the spline 20 also adopts a rectangular spline structure and the rectangular splines inside the No. 1 sun gear 5, No. 2 sun gear 22, and No. 3 sun gear 18 in the planetary gear system I, planetary ...

Embodiment 2

[0023] Embodiment 2: as Figure 1-6 As shown, a planetary gear train transmission with adjustable gears includes planetary gear system I, planetary gear system II, planetary gear system III, output shaft system, planet carrier fixed front end cover 1, planet carrier fixed rear end cover 21, Ring gear end cover 8, stepped ring gear 14; the output shaft system includes output shaft 3, sleeve 4, slidable sleeve 19, slidable spline 20, spring 23, deep groove ball bearing I2, deep groove Ball bearing Ⅱ7, deep groove ball bearing Ⅲ15, the outside of the output shaft 3 is stepped, and the largest part of the middle diameter of the output shaft 3 adopts the outer rectangular spline structure and the inner rectangular spline structure of the slidable spline 20, which can slide The outside of the spline 20 also adopts a rectangular spline structure and the rectangular splines inside the No. 1 sun gear 5, No. 2 sun gear 22, and No. 3 sun gear 18 in the planetary gear system I, planetary ...

Embodiment 3

[0025] Embodiment 3: as Figure 1-6 As shown, a planetary gear train transmission with adjustable gears includes planetary gear system I, planetary gear system II, planetary gear system III, output shaft system, planet carrier fixed front end cover 1, planet carrier fixed rear end cover 21, Ring gear end cover 8, stepped ring gear 14; the output shaft system includes output shaft 3, sleeve 4, slidable sleeve 19, slidable spline 20, spring 23, deep groove ball bearing I2, deep groove Ball bearing Ⅱ7, deep groove ball bearing Ⅲ15, the outside of the output shaft 3 is stepped, and the largest part of the middle diameter of the output shaft 3 adopts the outer rectangular spline structure and the inner rectangular spline structure of the slidable spline 20, which can slide The outside of the spline 20 also adopts a rectangular spline structure and the rectangular splines inside the No. 1 sun gear 5, No. 2 sun gear 22, and No. 3 sun gear 18 in the planetary gear system I, planetary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com