Electrode sheet and its manufacturing method and application

A production method and electrode sheet technology, which are applied in the directions of alkaline storage battery electrodes, hybrid capacitor electrodes, nickel storage batteries, etc., can solve the problems of difficult electrode sheets in the preparation process, and achieve the effect of good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

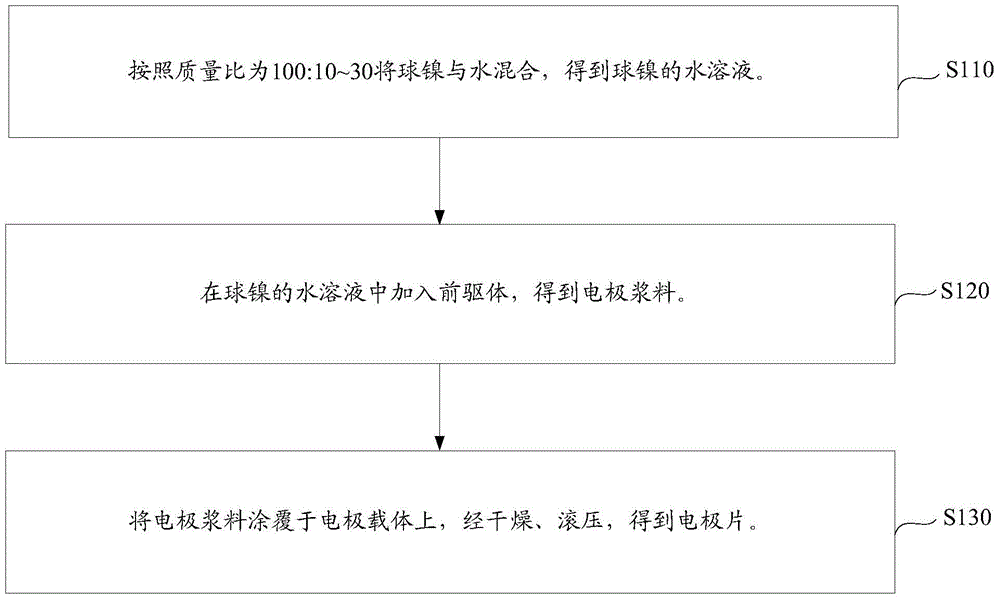

Method used

Image

Examples

Embodiment 1

[0037] (1) Put spherical nickel and water in a beaker according to the mass ratio of 100:20, mix and stir evenly to obtain an aqueous solution of spherical nickel.

[0038] (2) Add polyacrylic acid to the aqueous solution of spherical nickel in step (1), and stir evenly, wherein the mass ratio of spherical nickel to polyacrylic acid is 100:0.01 to obtain an electrode slurry.

[0039] (3) Coating the electrode slurry on the foamed nickel, drying at 40°C, and rolling to obtain an electrode sheet.

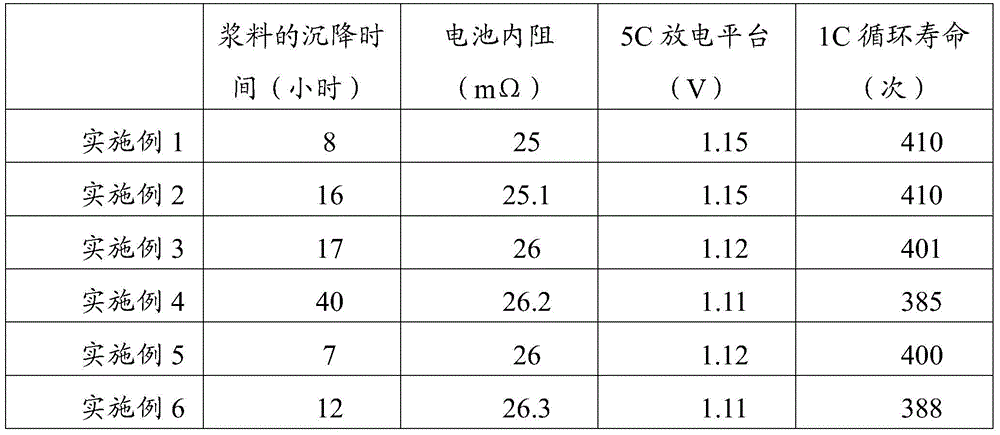

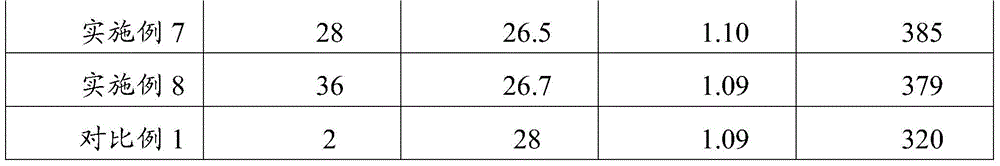

[0040] Store and observe the electrode slurry prepared in step (2), and record the time when the electrode slurry begins to settle. See Table 1 for the settling time. The electrode sheet obtained in step (3) is used as the positive electrode sheet, cut and spot-welded with nickel tabs, wound together with the negative electrode sheet and separator, and then injected, sealed and formed in sequence to make an AAA700 battery, and the battery is tested See Table 1 for the test data of th...

Embodiment 2

[0042] (1) Put spherical nickel and water in a beaker according to the mass ratio of 100:20, mix and stir evenly to obtain an aqueous solution of spherical nickel.

[0043] (2) Add polyacrylic acid to the aqueous solution of spherical nickel in step (1), and stir evenly, wherein the mass ratio of spherical nickel to polyacrylic acid is 100:0.3 to obtain an electrode slurry.

[0044] (3) Coating the electrode slurry on the foamed nickel, drying at 100°C, and rolling to obtain an electrode sheet.

[0045] Store and observe the electrode slurry prepared in step (2), and record the time when the electrode slurry begins to settle. See Table 1 for the settling time. The electrode sheet obtained in step (3) is used as the positive electrode sheet, cut and spot-welded with nickel tabs, wound together with the negative electrode sheet and separator, and then injected, sealed and formed in sequence to make an AAA700 battery and test the battery The internal resistance, the discharge pl...

Embodiment 3

[0047](1) Put spherical nickel and water in a beaker according to the mass ratio of 100:30, mix and stir evenly to obtain an aqueous solution of spherical nickel.

[0048] (2) Add polyacrylic acid to the aqueous solution of spherical nickel in step (1), and stir evenly, wherein the mass ratio of spherical nickel to polyacrylic acid is 100:0.5 to obtain an electrode slurry.

[0049] (3) Coat the electrode slurry on the steel mesh, dry at 270°C, and roll to obtain the electrode sheet.

[0050] Store and observe the electrode slurry prepared in step (2), and record the time when the electrode slurry begins to settle. See Table 1 for the settling time. The electrode sheet obtained in step (3) is used as the positive electrode sheet, cut and spot-welded with nickel tabs, wound together with the negative electrode sheet and separator, and then injected, sealed and formed in sequence to make an AAA700 battery, and the battery is tested See Table 1 for the test data of the internal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com