Inert gas purification method

A technology of inert gas and purification method, applied in the directions of inert gas compound, separation method, gas treatment, etc., can solve the problems of increasing cost, inability to effectively purify inert gas, large amount, etc., and achieve the effect of effective purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach )

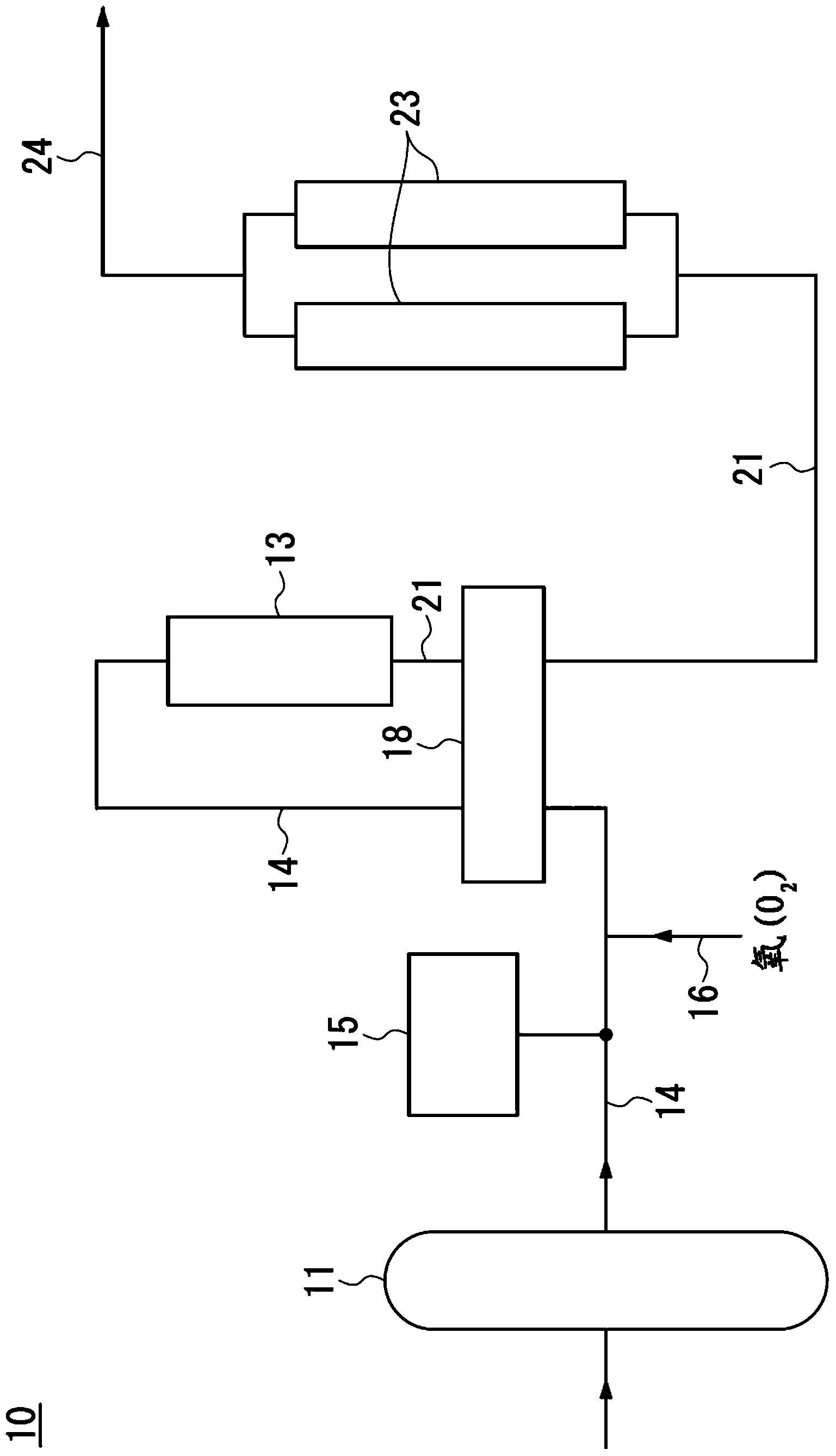

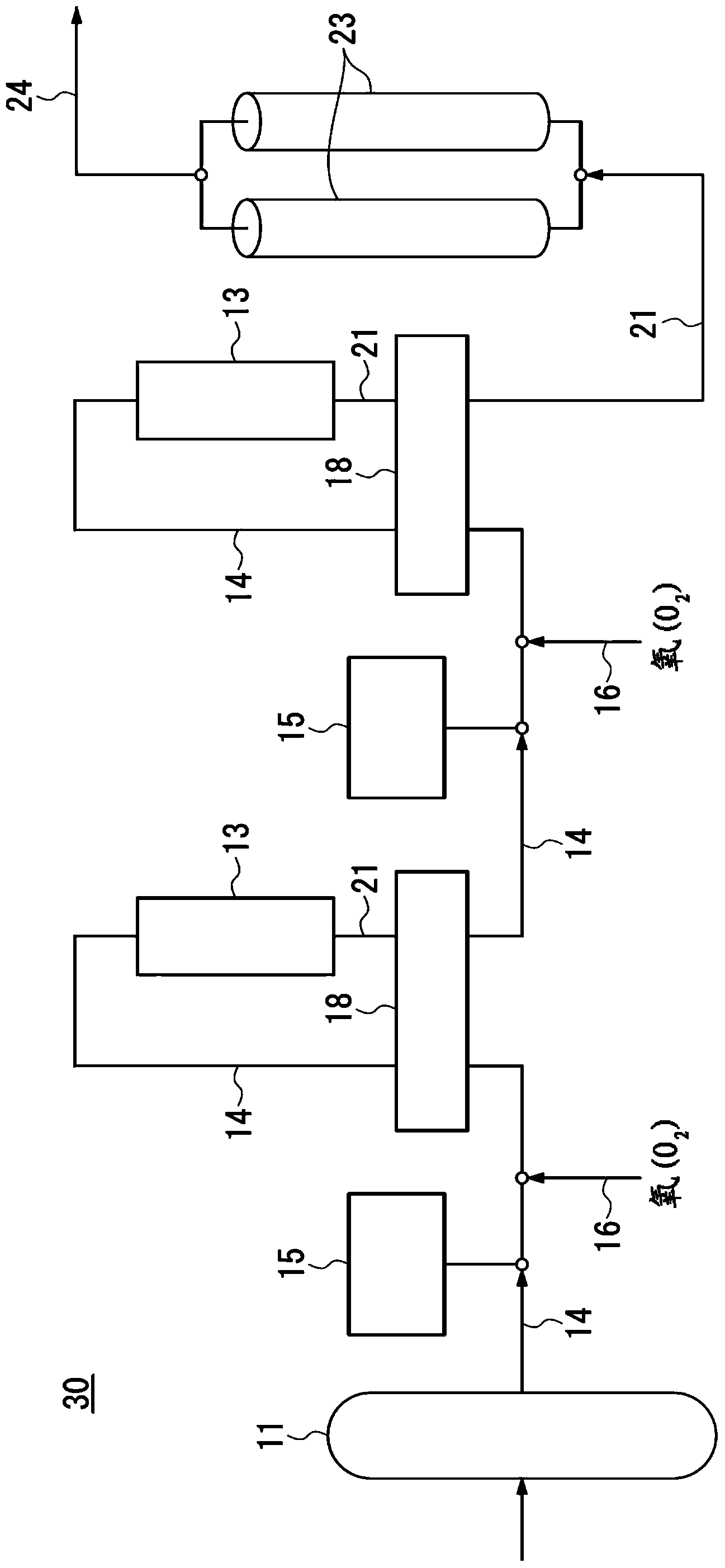

[0041] figure 1 It is a figure which shows the schematic structure of the inert gas purification apparatus concerning embodiment of this invention.

[0042] refer to figure 1 , The inert gas purification device 10 of the present embodiment has a buffer tank 11, a catalyst tower 13, a first gas delivery line 14, a hydrogen concentration analyzer 15, an oxygen supply line 16, a heat exchanger 18, a second gas delivery line 21, an adsorption Separation section 23 and gas discharge line 24 .

[0043] The buffer tank 11 stores raw material gas (hereinafter referred to as "raw material gas A") which is an inert gas containing carbon monoxide and hydrogen (more specifically, exhaust gas from a heating furnace (not shown) for melting ceramics and metals, etc.). ”) cans. The buffer tank 11 is connected to a first gas delivery line 14 . The source gas is not particularly limited as long as it is an inert gas containing carbon monoxide and hydrogen. For example, the source gas A is ...

Embodiment

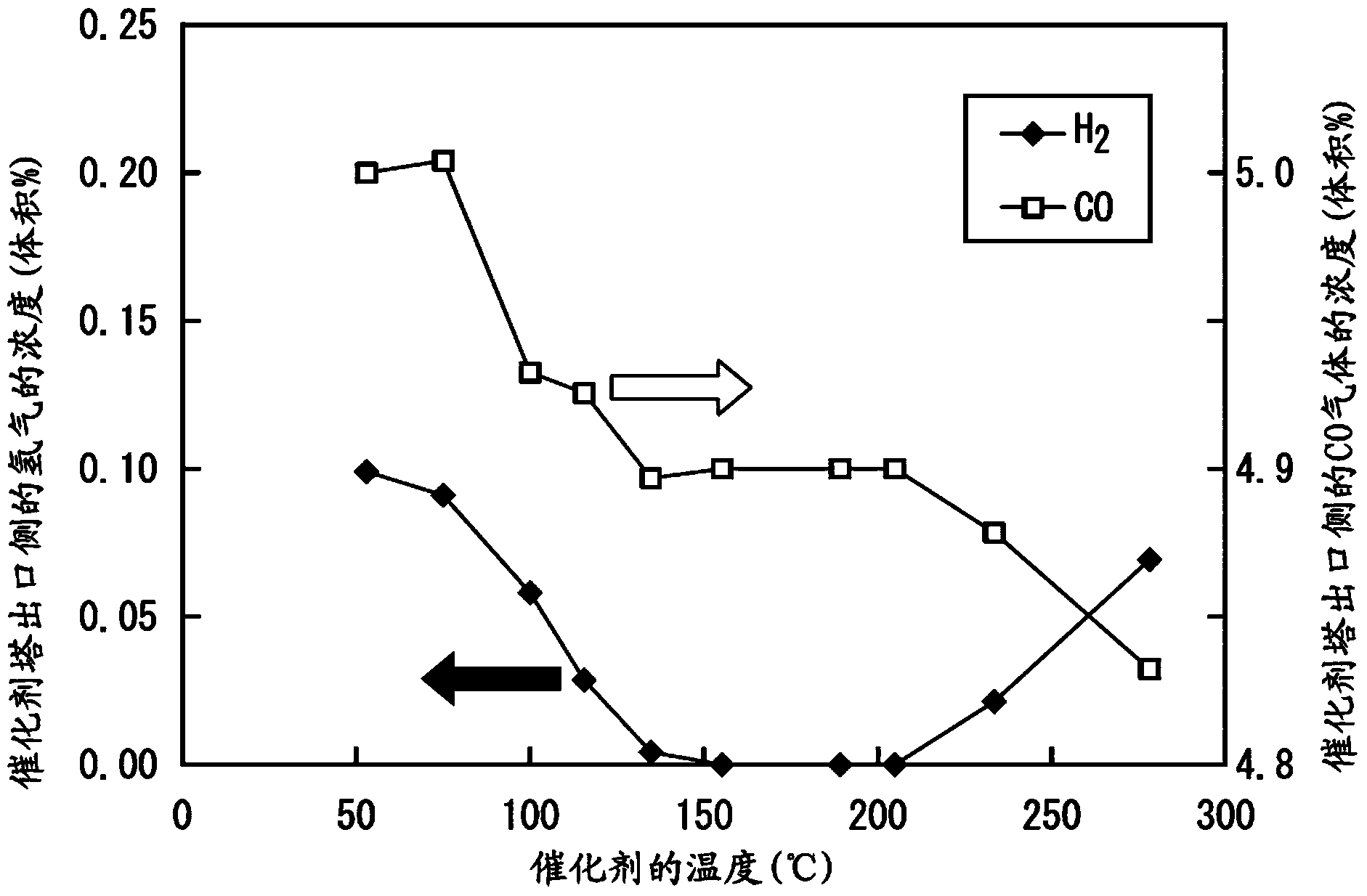

[0071] Next, the excellent effect under the preferred conditions (temperature conditions of the catalyst) of the first step in the method of the present invention will be described. In addition, the following examples illustrate preferred examples of the present invention, and the present invention is not limited thereto.

[0072] In the evaluation, using the figure 1 The unit shown is the same as the inert gas refining unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com