Current detection circuit module

A current detection circuit and detection circuit technology, applied in the direction of measuring current/voltage, only measuring current, voltage/current isolation, etc., can solve the problems of weak resistance to mechanical shock and large driving shock, and achieve improved mechanical shock resistance. The effect of simplifying the inspection process and increasing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

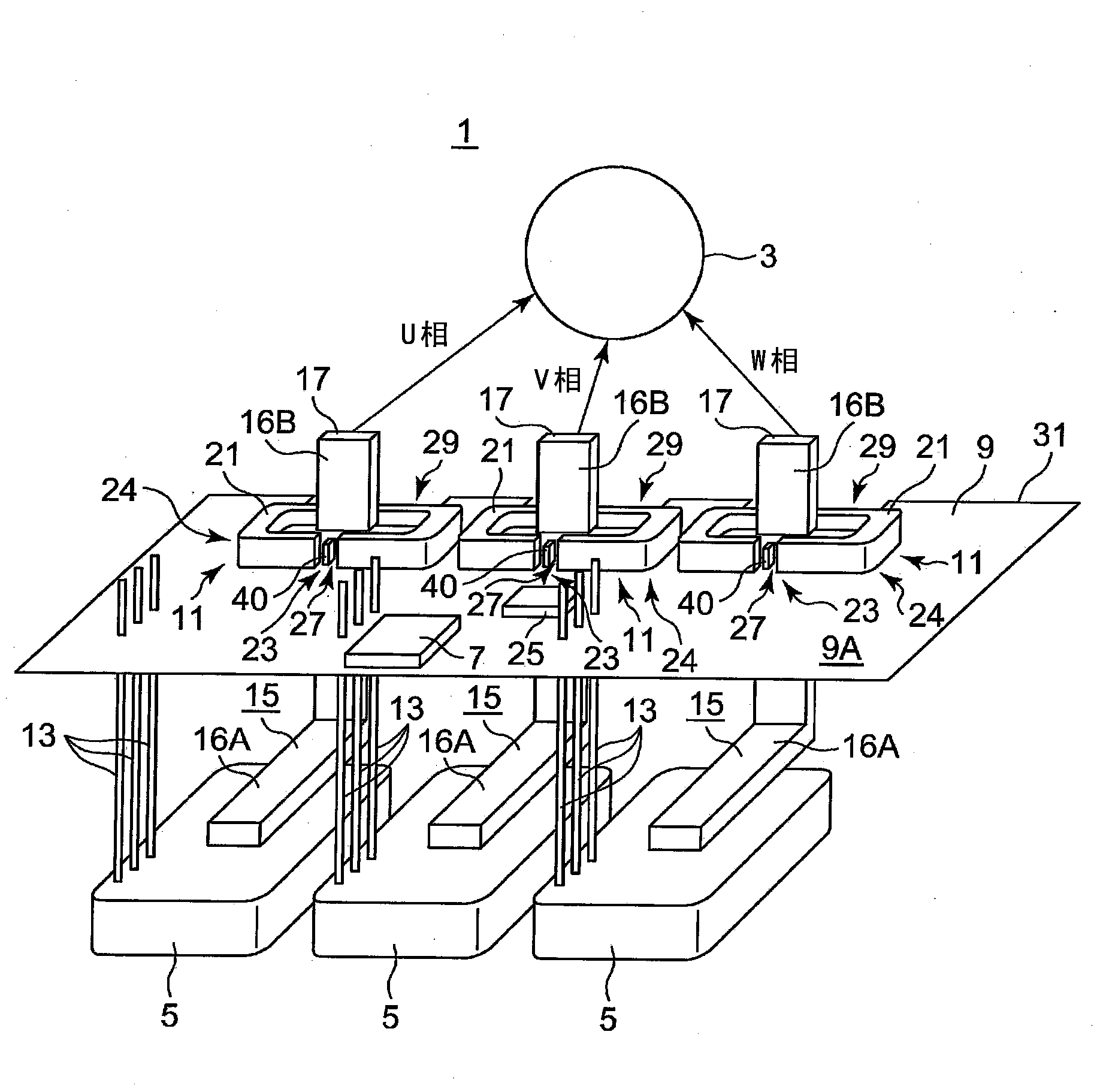

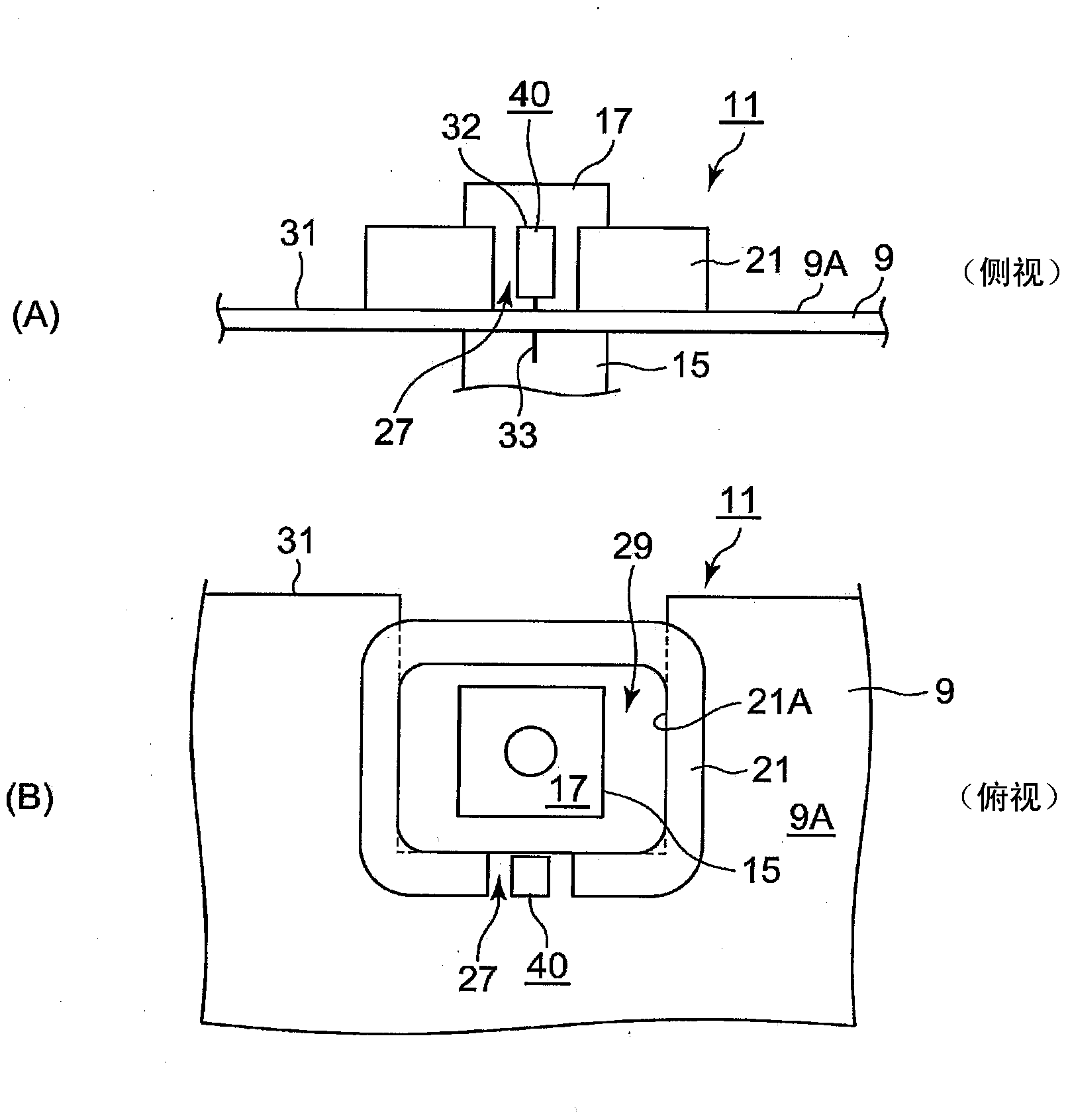

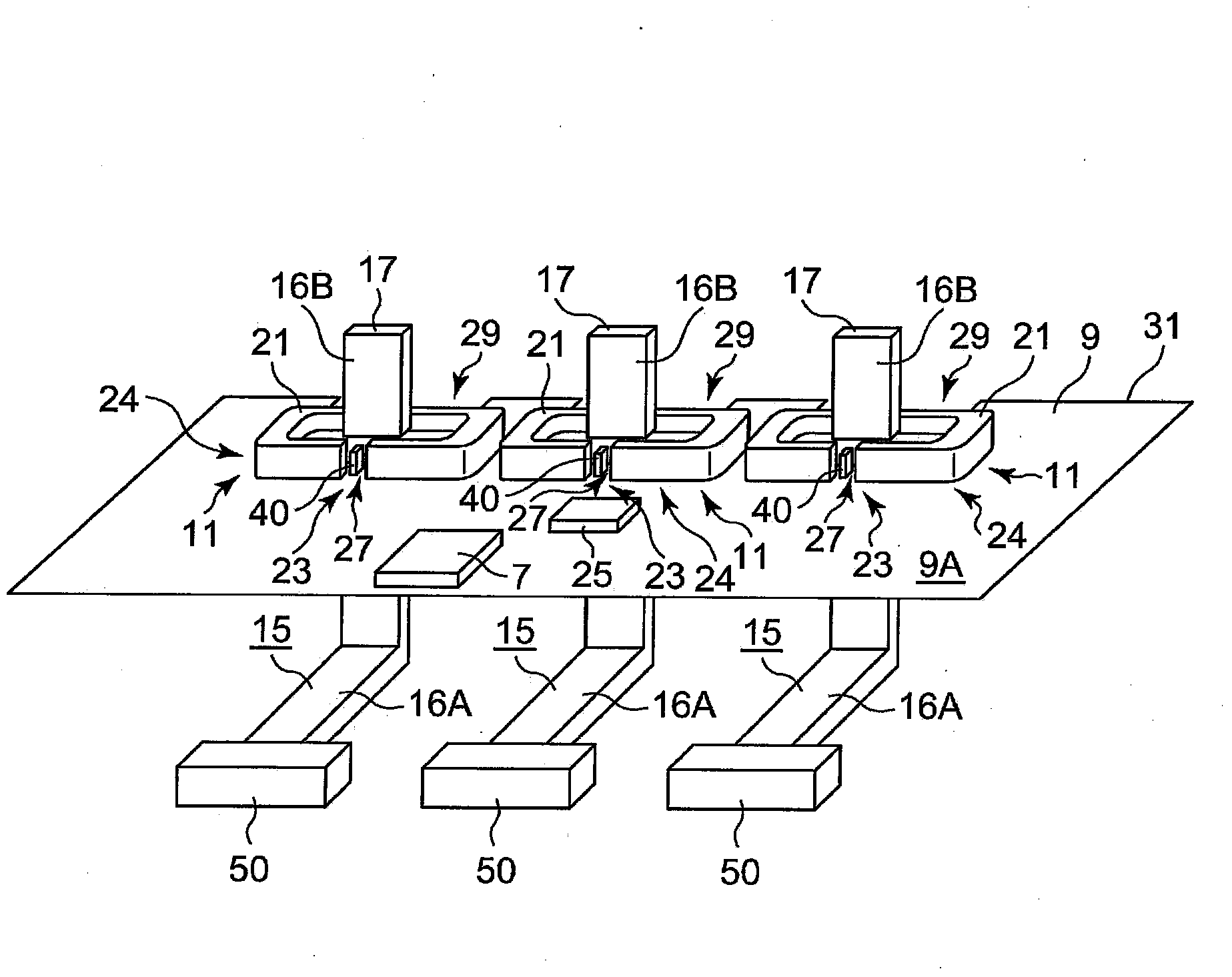

[0070] figure 1 It is a figure which schematically shows the structure of the three-phase inverter circuit module 1 which concerns on this embodiment.

[0071] The three-phase inverter circuit module 1 is installed in an electric vehicle such as an electric car, and controls a driving motor or a generator (hereinafter, they are referred to as "three-phase rotating electric machines" and given symbol 3), as shown in figure 1 As shown, it includes: a power module 5 , a control IC 7 , a control circuit board 9 on which the control IC 7 is mounted, and a current detection circuit module 11 mounted on the control circuit board 9 together with the control IC 7 .

[0072] The power module 5 includes, for example, a pair of switching elements (see Figure 13 ) is modularized into a package, and is set according to each phase of the three phases. The configuration of the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com