Inoculation device and inoculation method

The technology of an inoculation device and a tower can be applied to horticultural methods, botanical equipment and methods, horticulture, etc., and can solve the problems of blocking the middle spore powder, hard-to-pathose leaves, and many spore powders, and achieves a highly repeatable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

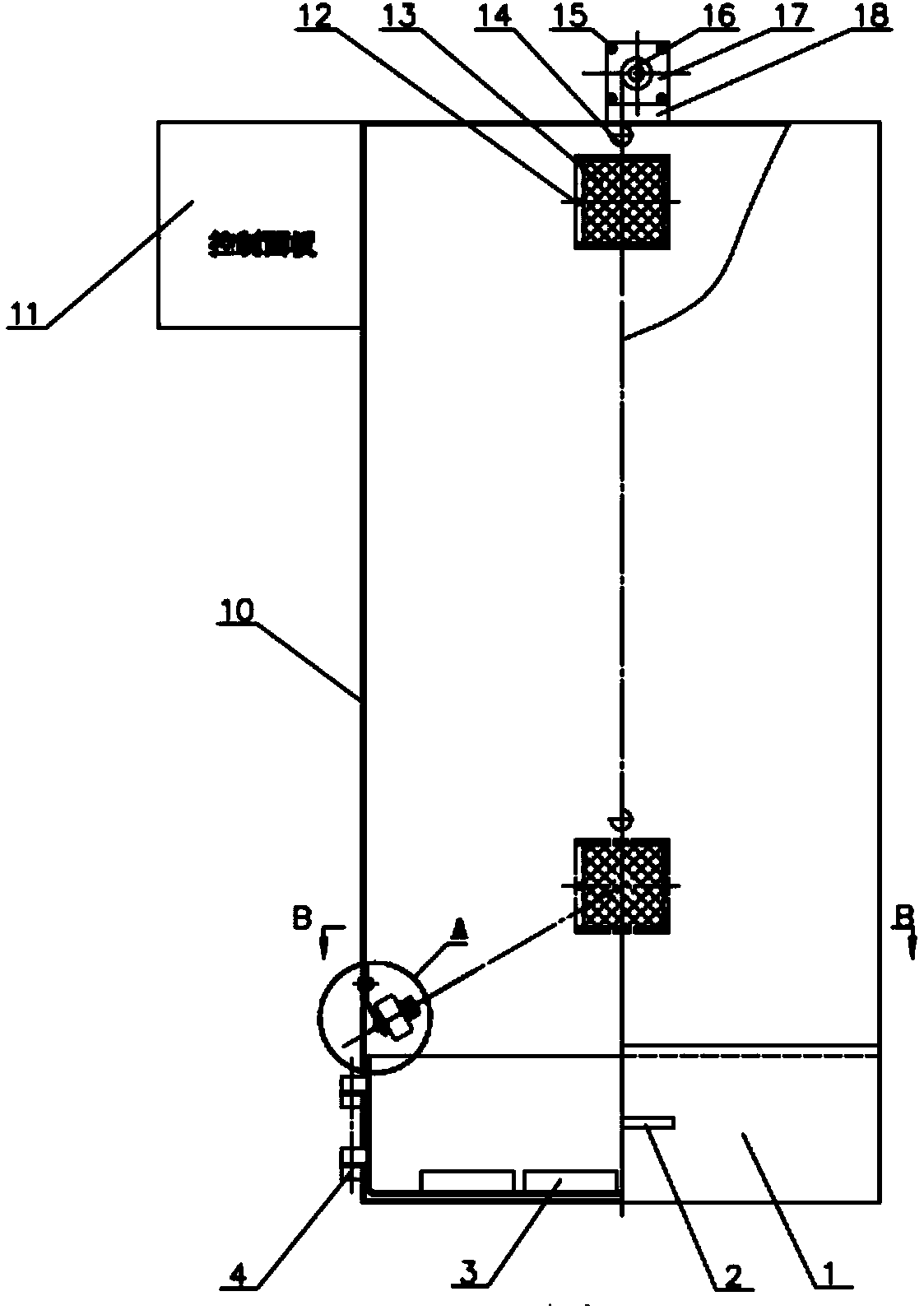

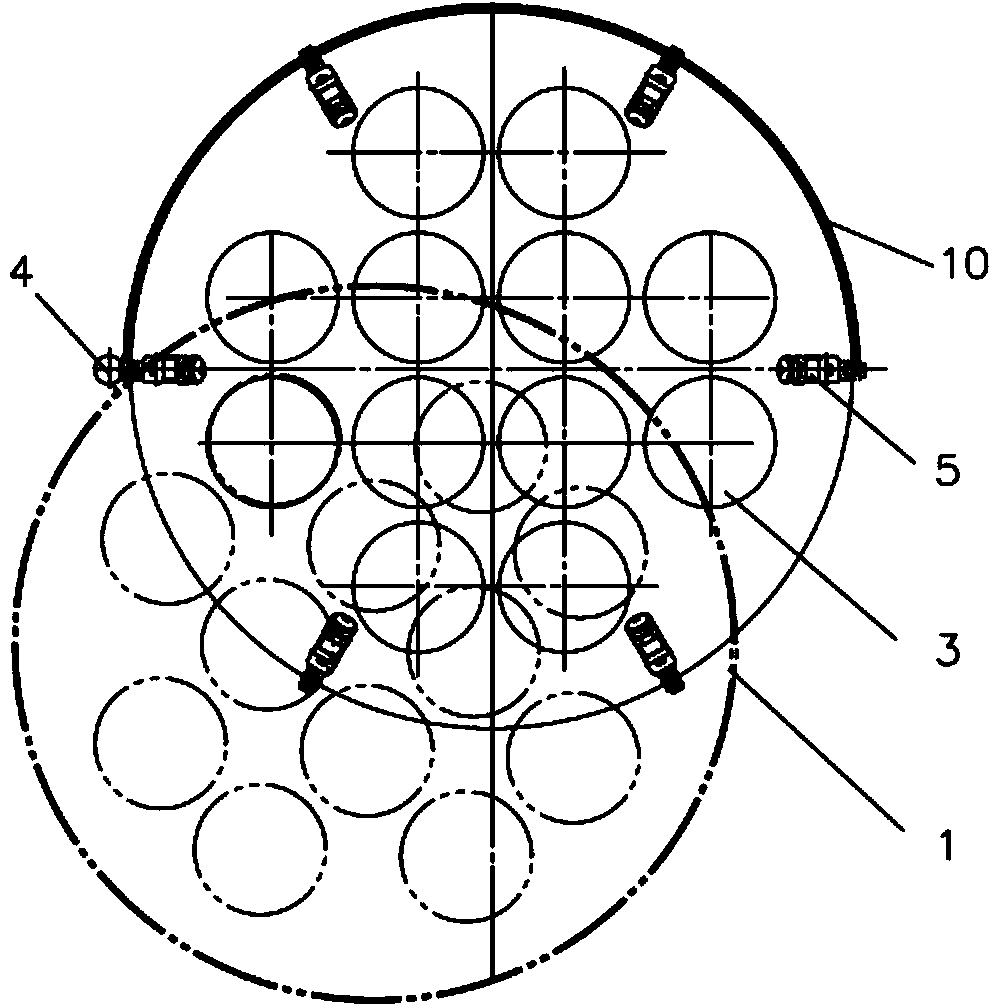

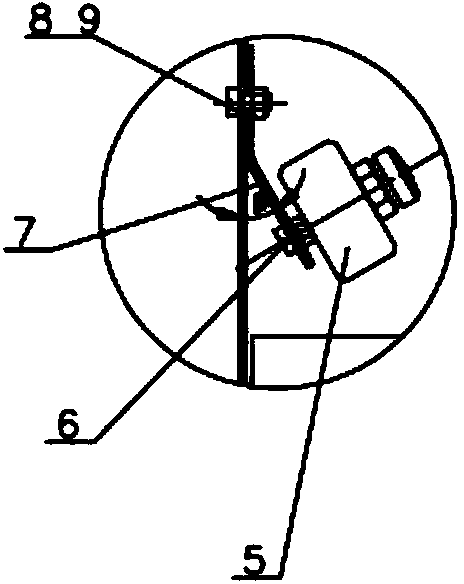

[0026] The basic structure of the inoculation device of the present embodiment is as follows: figure 1 , figure 2 As shown, a stepping motor 17 is installed on the top of the vertical tower 10, and the rotating positioning wheel 16 at its end hangs a liftable stainless steel mesh cage 13 from the center of the tower 10 top by a positioning rope 14, and the stainless steel mesh cage 13 is equipped with the cage door that can open and close by mesh cage door pin 12. The lower side wall of the tower 10 is respectively equipped with six pneumatic nozzles 5 inclined upward at 30° (β=30°) through six circumferentially evenly distributed L-shaped mounting plates 7 (see image 3 ), the β angle of the L-shaped mounting plate 7 can be adjusted as required. Spray diffusion angle formation of six pneumatic nozzles 5 Figure 4 Can contain the air-flow confluence area of cage 13 (see Figure 5 ). The height of the tower 10 ensures that the extension line of the axis of the pneumatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com