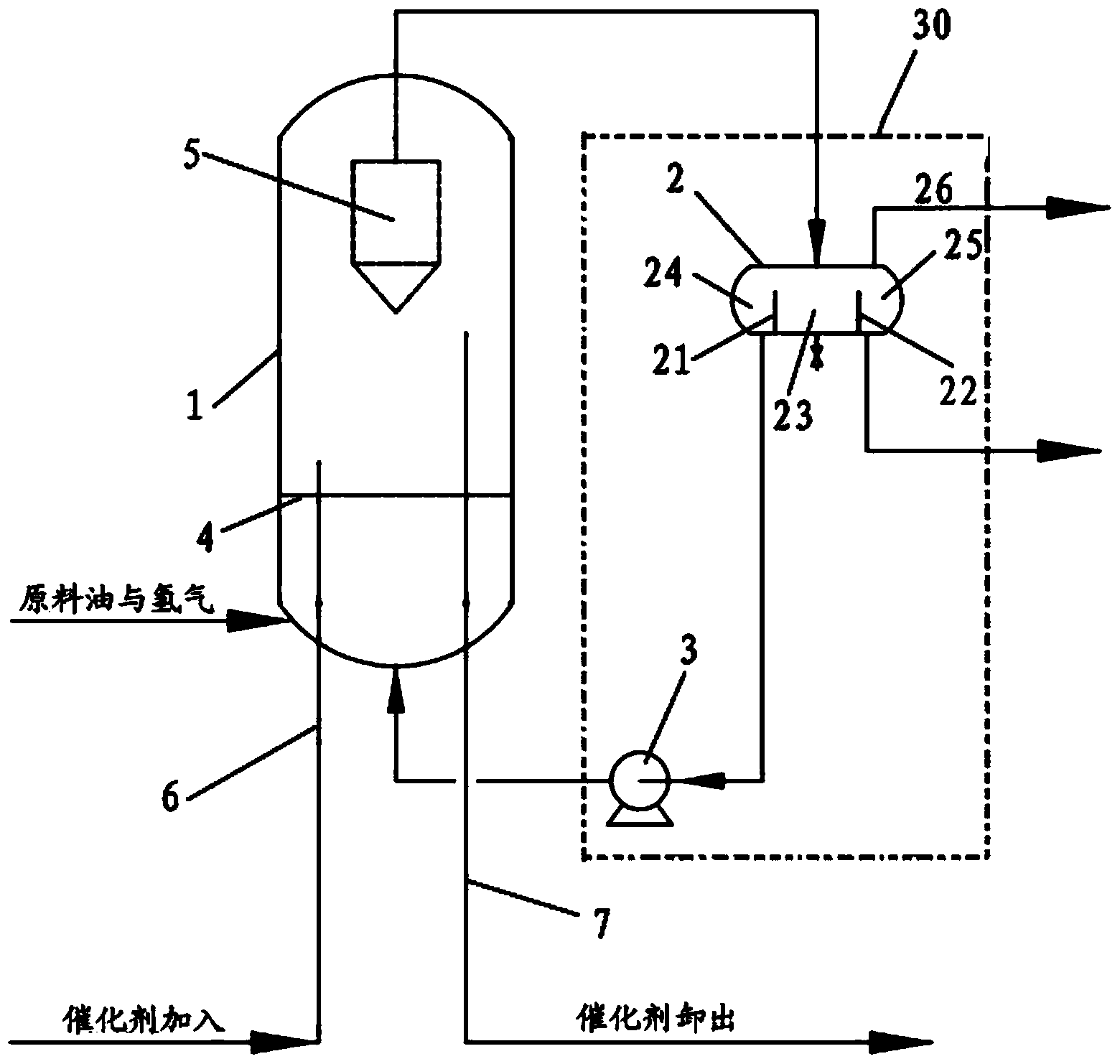

Fluidized bed reactor

A fluidized bed reactor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low space utilization rate and complex internal structure of the reactor, and improve the operation flexibility and stability. The effect of prolonging the residence time and increasing the effective volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Coal liquefied oil hydrogenation test is carried out by using the fluidized bed reactor of the present invention. The reactor shell is 35m high, including the middle straight section and the upper and lower elliptical heads. The straight section is 31m high and 4.5m in diameter; 0.1m, the inlet end of the catalyst unloading pipeline is 20m away from the distributor; the structure of the hot high-pressure separator is as follows figure 1 As shown, the diameter (height) is 5m, the first and second baffles are 3m high, the middle part is 5m wide, and the first and second parts are 2m wide.

[0037] The hydrogenation catalyst used in the test is a hydrogenation catalyst with alumina as the carrier, and its manufacturer is Beijing Sanju Environmental Protection New Materials Co., Ltd., and the brand is FFT-1B. Above the distributor in the reactor shell is the effective volume of the reactor, and the filling volume of the catalyst in the reactor is 60% of the effective volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com