Plastic vacuum cavity plate

A vacuum cavity and plastic technology, which is applied in the improvement of windows/doors, building components, climate change adaptation, etc., can solve the problems of thermal insulation performance and sound insulation performance that cannot be improved, poor thermal insulation performance and sound insulation performance, and large space occupation, etc. problems, to achieve the effect of huge market development potential, low equipment investment costs, and reduced emission processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

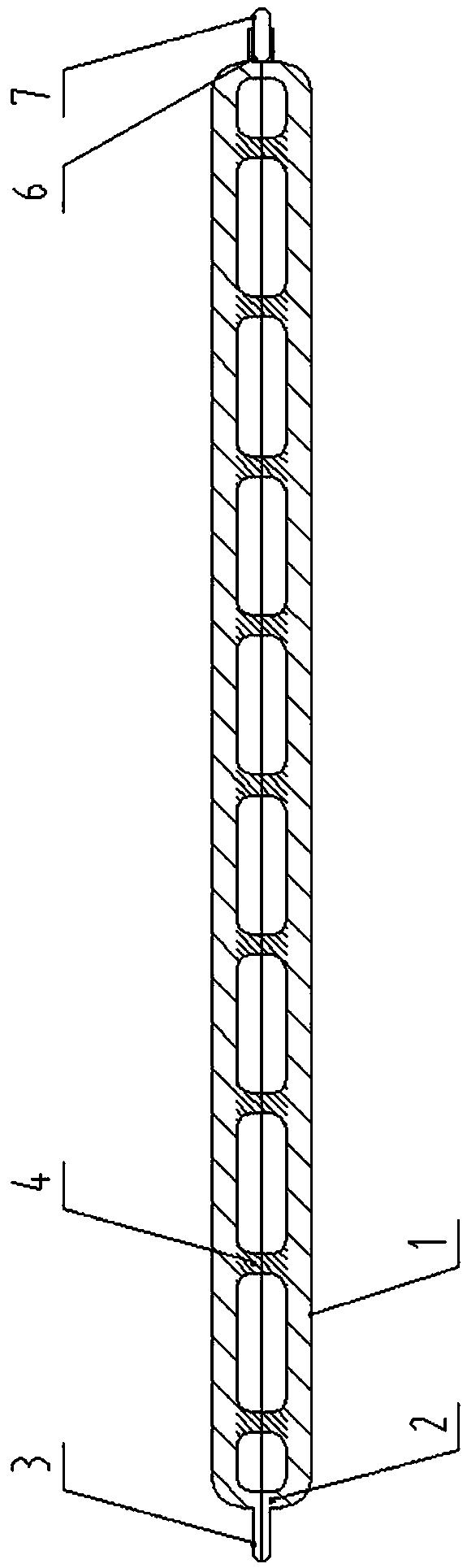

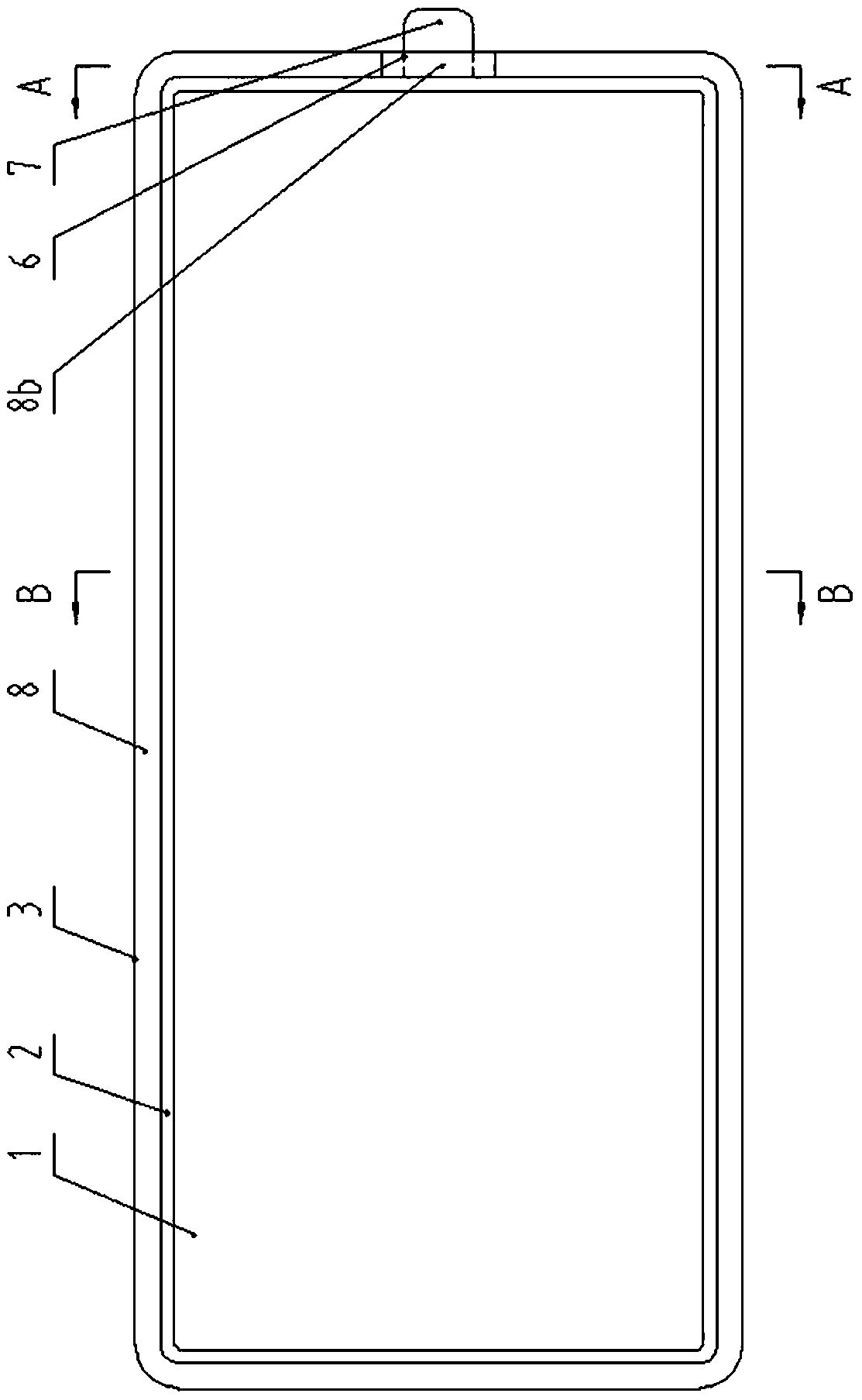

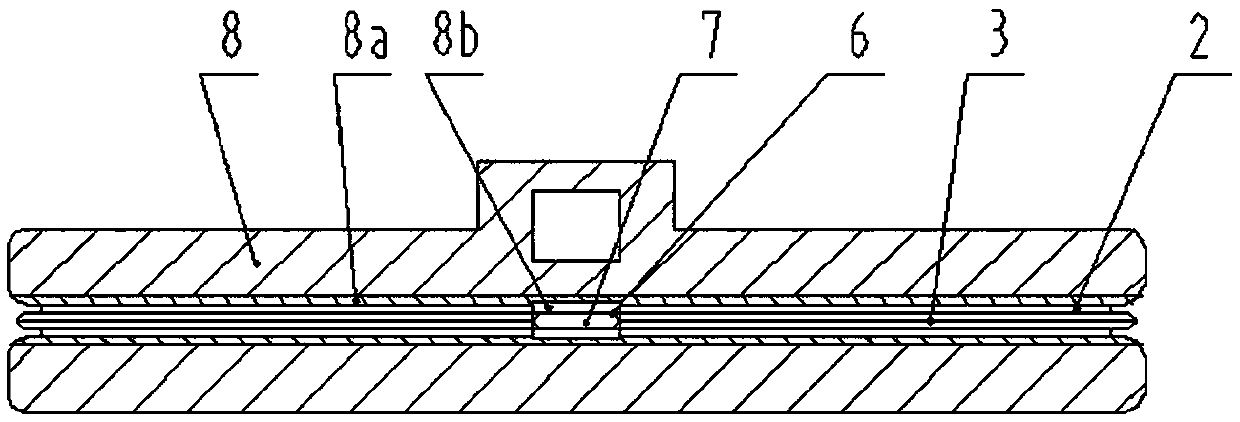

[0009] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The present invention is as figure 1 , 2 , In the embodiment shown in 3,4,5,6, the transparent plastic vacuum chamber plate that vacuum chamber thickness is more than 2 millimeters or one side of the transparent plastic vacuum chamber plate that vacuum chamber thickness is more than 6 millimeters, glues Tempered glass of the same size, and the other side is glued with low-emissivity glass of the same size to assemble a composite tempered flat vacuum glass with thickened vacuum chamber, good thermal insulation and noise insulation performance, which can be installed in building doors and windows, transportation equipment On the doors and windows on the home appliances, on the doors on the household appliances, and on the transparent panels on the flat solar water heaters.

[0010] The invention as figure 2 , 5 . In the embodiment shown in 7, the opaque plastic vacuum chamber plate with a vacuum chamber thickness of mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com