Supported binary metal oxide nano-catalyst and preparation method thereof

A nano-catalyst and binary metal technology, applied in the field of nano-materials, can solve the problems of difficult large-scale promotion and application, high price, etc., and achieve the effect of cheap raw materials, less demand, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

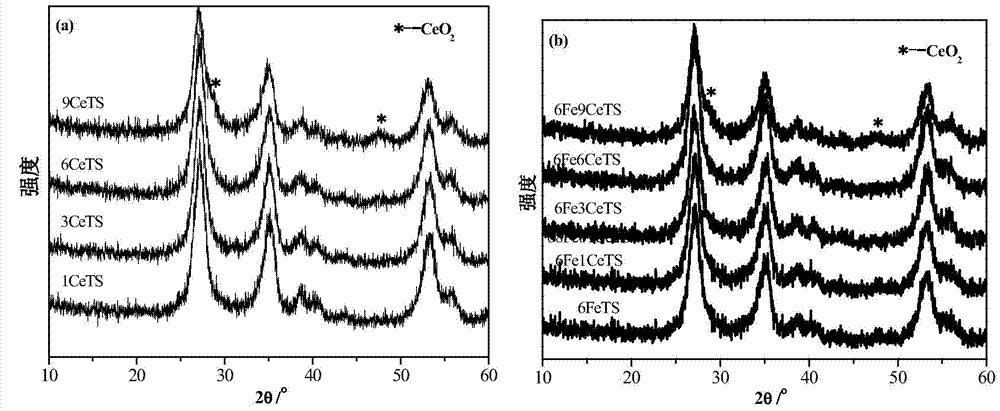

[0032] 1. Ti 0.5 sn 0.5 o 2 Preparation of composite oxides: TiCl 4 solution and SnCl 4 ·5H 2 O was mixed according to the Ti:Sn molar ratio of 1:1, and the mixed solution was stirred for 1 hour, then slowly and uniformly added dilute ammonia water to the mixed solution while stirring until the pH=10, and the precipitation was complete. Then the resulting precipitate was washed with dilute ammonia water and suction filtered, then dried in an oven at 110°C for 12 hours, and ground; then roasted in a muffle furnace at 550°C for 4 hours to obtain Ti 0.5 sn 0.5 o 2 Composite oxides, spare.

[0033] 2. 6% Fe 2 o 3 / Ti 0.5 sn 0.5 o 2 Preparation of nanocatalyst: 1g Ti 0.5 sn 0.5 o 2 Put the composite oxide as a carrier into 7.04ml, 0.1mol L -1 Fe(NO 3 ) 3 Ultrasonic immersion in the solution for 2 hours, the ultrasonic frequency is 2000 Hz; then use 120 ° C oil bath to stir and evaporate the water; vacuum dry at 90 ~ 100 ° C for 10 hours, the vacuum degree is 400 P...

Embodiment 2

[0036] 1. Ti 0.5 sn 0.5 o 2 Preparation of composite oxides: TiCl 4 solution and SnCl 4 ·5H 2 O was mixed according to the Ti:Sn molar ratio of 1:1, and the mixed solution was stirred for 2 hours. Then, while stirring, dilute ammonia water was slowly and uniformly dropped into the mixed solution until the pH=10, and the precipitation was complete. Then the resulting precipitate was washed with dilute ammonia water and suction filtered, then dried in an oven at 120°C for 16 hours, and ground; then roasted in a muffle furnace at 550°C for 5 hours to obtain Ti 0.5 sn 0.5 o 2 Composite oxides, spare.

[0037] 2. 6% Fe 2 o 3 / 1%CeO 2 / Ti 0.5 sn 0.5 o 2 The preparation of binary metal oxide nano-catalyst comprises the following steps:

[0038] (1) Put 1g Ti 0.5 sn 0.5 o 2 Put the composite oxide as a carrier into 0.88ml0.1mol L -1 Ce(NO 3 ) 3 Ultrasonic immersion in the solution for 1.5h, the ultrasonic frequency is 2000Hz; then use a 120°C oil bath to stir and e...

Embodiment 3

[0042] 1. Ti 0.5 sn 0.5 o 2 The preparation of composite oxide is the same as in Example 1.

[0043] 2. 6% Fe 2 o 3 / 3%CeO 2 / Ti 0.5 sn 0.5 o 2 The preparation of binary metal oxide nano-catalyst comprises the following steps:

[0044] (1) Put 1g Ti 0.5 sn 0.5 o 2Put the composite oxide as a carrier into 2.64ml0.1mol L -1 Ce(NO 3 ) 3 Ultrasonic immersion in the solution for 1.5h, the ultrasonic frequency is 2000Hz; then use a 120°C oil bath to stir and evaporate to dryness; vacuum dry at 90-100°C for 10h, the vacuum degree is 400Pa; grind through a 160-mesh sieve. Calcined at 500°C for 4h in air atmosphere to get 3%CeO 2 / Ti 0.5 sn 0.5 o 2 Nano catalyst;

[0045] (2) The 3%CeO obtained in step (1) 2 / Ti 0.5 sn 0.5 o 2 Put the nano catalyst into 7.04ml0.1mol L -1 Fe(NO 3 ) 3 Ultrasonic immersion in the solution for 2 hours, the ultrasonic frequency is 2000 Hz; then use 120 ° C oil bath to stir and evaporate the water; vacuum dry at 90 ~ 100 ° C for 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

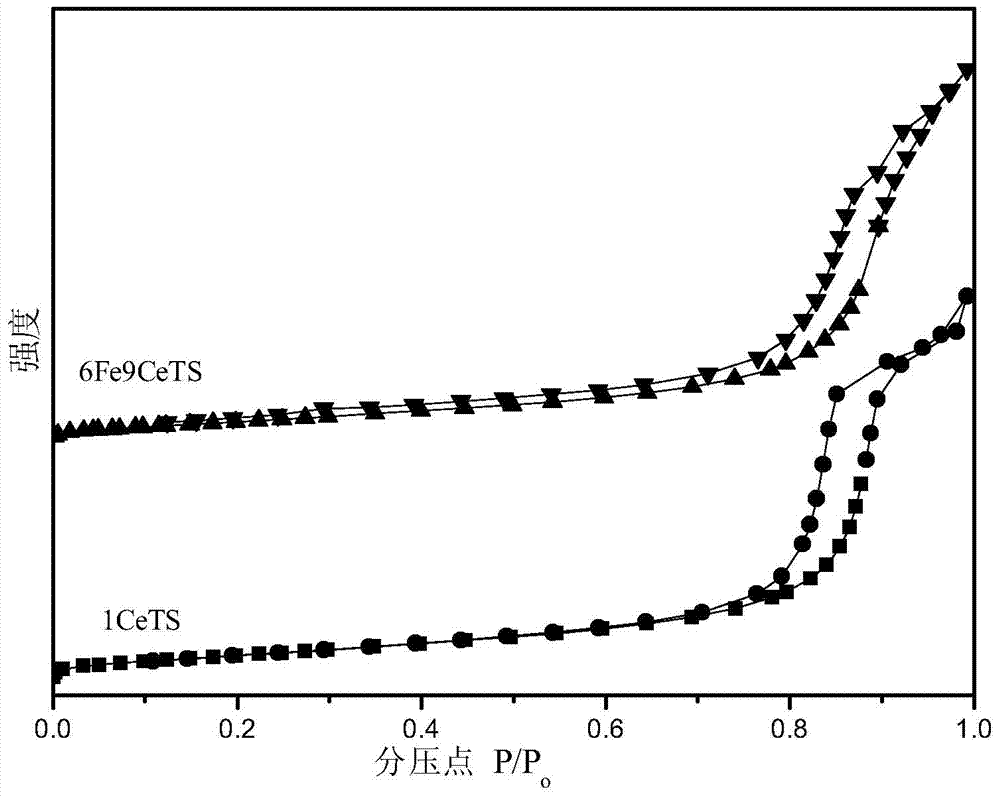

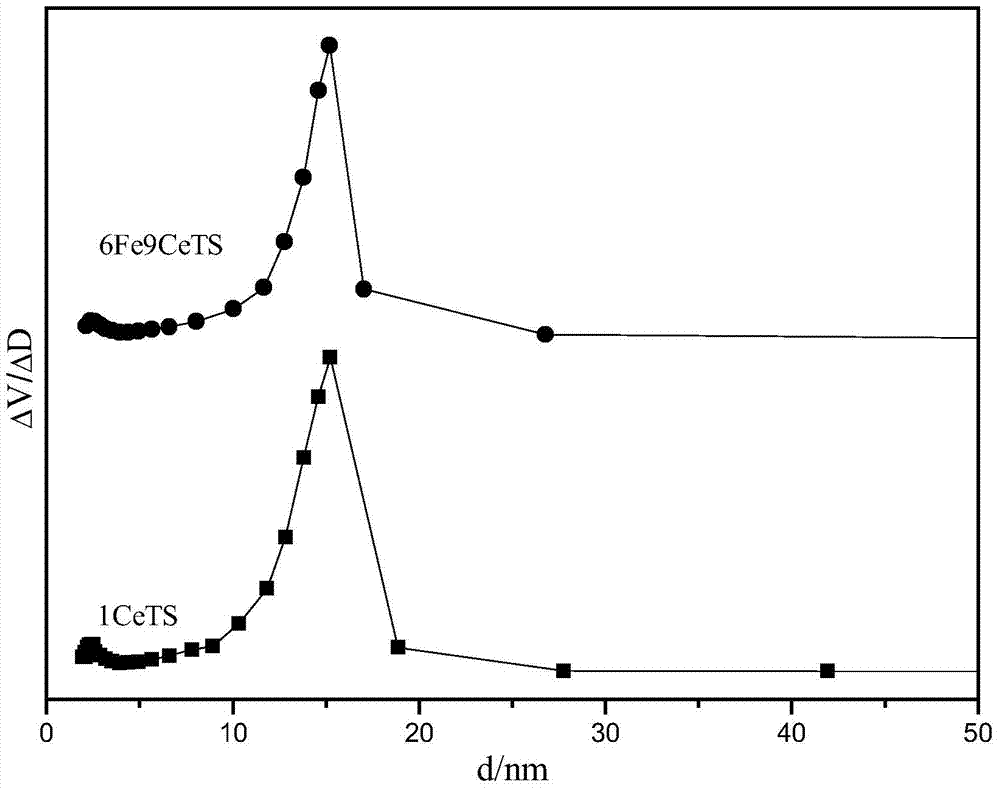

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com