Medium-frequency ultrasonic atomizing spray head with polarizing in radial thickness direction

A radial thickness, ultrasonic atomization technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of inability to spray, working frequency not higher than 120KHz, inconvenient processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

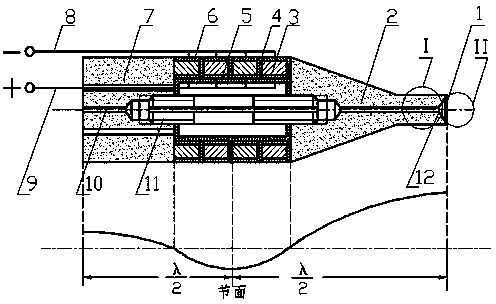

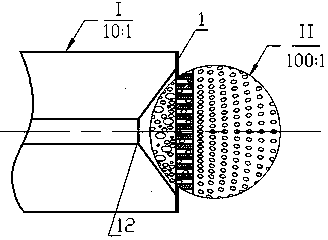

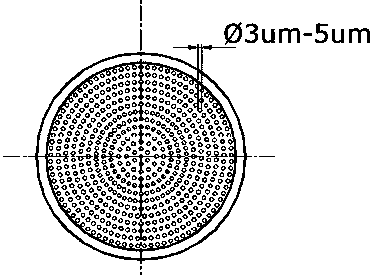

[0024] like figure 1 , figure 2 and image 3 As shown, the size of the entire ultrasonic atomizing nozzle is one ultrasonic pressure wave wavelength. The middle of the piezoelectric ceramic crystal stack is a nodal plane, and the distance between the nodal plane and the left and right end faces of the ultrasonic nebulizer is 1 / 2 wavelength respectively. Both the inner and outer walls of the piezoelectric ceramics 3 are coated with a silver layer 6 , and the right side of each piezoelectric ceramic 3 is pasted with an insulating ring 4 . Four piezoelectric ceramics 3 polarized in the radial thickness direction coaxially form a piezoelectric ceramic crystal pile, the left end of the piezoelectric ceramic crystal pile is connected to the rear cover plate 7, the rear cover plate 7 is a SiC ceramic crystal pile, and the right end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com