Method for forming floor with wicker as core veneer through once compression molding

A molding and wicker technology, which is applied in the field of one-time molding flooring, can solve problems such as degumming, bubbling, and large wood waste, and achieve the effects of reducing warping deformation, reducing manufacturing costs, and saving wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

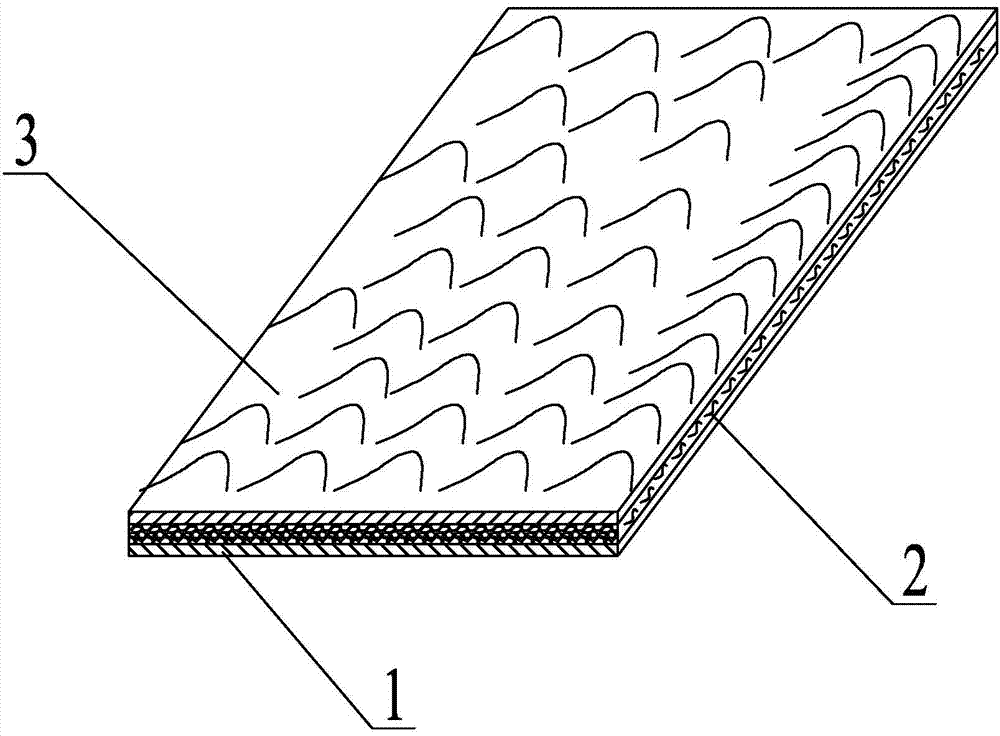

[0011] Specific implementation mode one: combine figure 1 Illustrate that the method of using wicker as a core board to mold the floor at one time in this embodiment is realized in the following steps:

[0012] Step 1: rolling the truncated wicker into a curtain-shaped wooden bundle 2, removing the bark, and then drying, dipping the dried curtain-shaped wooden bundle 2 in glue, and drying the dipped curtain-shaped wooden bundle 2 again, Dried to a moisture content of 15% to 17%;

[0013] Step 2: Put the backboard 1 into the mold, place the dried rubber-impregnated curtain-like wood bundle 2 as a core board on the backboard 1, place the surface board 3 on the curtain-like wood bundle 2, and perform pre-pressing, The pre-pressing pressure is 13Mpa ~ 18MPa to form a pre-pressed slab;

[0014] Step 3: drying and curing the pre-pressed slab together with the mold to form a wicker three-layer composite floor. The curing temperature is 120°C-140°C and the curing time is 3min / mm-5mi...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination figure 1 Illustrate that the method of using wicker as a core board molding floor in the present embodiment also includes step 4: follow-up treatment; sanding the outer surfaces of the front board 3 and the back board 1 of the wicker three-layer composite floor, and then The sides of the wicker three-layer laminate flooring are milled and grooved. The two sides of the wicker three-layer composite floor are sanded to make the surface clean and beautiful, which is convenient for subsequent processing such as painting. The side of the wicker three-layer composite floor is milled with tenons and grooves for easy paving, so that the floor is integrated and mutually restricted, reducing deformation. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 1 Note that the front board 3 in steps 3 and 4 of this embodiment is a sawn thin board, the thickness of the front board 3 is 4 mm to 6 mm, the back board 1 is poplar veneer or birch veneer, and the thickness of the back board 1 is 2 mm to 4 mm . Sawn veneers are generally precious tree species, such as ash, oak, teak and red sandalwood, etc., the purpose is to decorate beautifully, the wood is hard, and avoid depressions caused by bumps; At the same time, the cost is reduced. In addition, the use of the front panel 3 and the back panel 1 not only improves the dimensional stability of the wicker three-layer composite floor, but also reduces the warping deformation of the wicker three-layer composite floor. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com