Online purifying system of waste helium generated in optical fiber manufacturing

A technology of helium and optical fibers, which is applied in the field of optical fiber manufacturing waste helium on-line purification system, can solve the problem of difficulty in online recovery and secondary supply of helium-rich tail gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

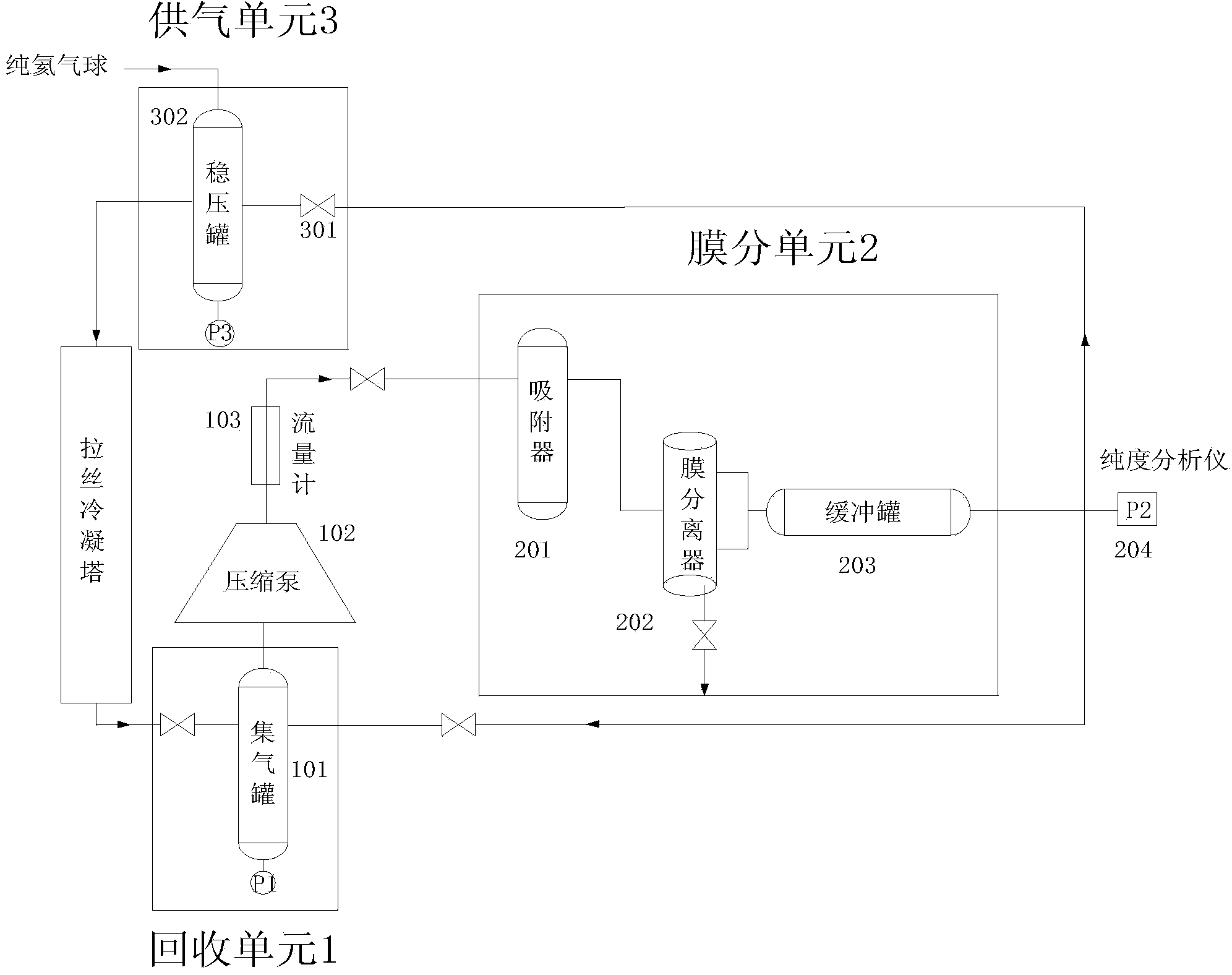

[0016] Such as figure 1 shown. Optical fiber manufacturing waste helium online purification system, including recovery unit 1, membrane separation unit 2, and gas supply unit 3. Wherein recovery unit 1 comprises gas collection tank 101, booster pump 102, flow meter 103; Membrane sub-unit 2 comprises adsorber 201, membrane separator 202, buffer tank 203, purity detector 204; Gas supply unit 3 comprises pressure regulating valve 301. A surge tank 302.

[0017] The recovery unit 1 includes a gas collection tank 101 , a booster pump 102 , and a flow meter 103 . The helium-rich tail gas in each optical fiber drawing cooling tower and preform manufacturing device is subjected to the negative pressure suction generated by the booster pump 102, flows into the gas collection tank 101 through the pipeline, and the helium-rich tail gas in the gas collection tank 101 is then compressed by the booster pump 102 After boosting, it enters the membrane division unit 2 through pipeline conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com