Humic acid root fertilizer and production method thereof

A production method and acid technology, applied in the field of humic acid rooting fertilizer and its production, can solve the problems of limited effect or function, too strong crop specificity, complicated operation procedures, etc., to achieve simple and easy operation, and promote root extension Long and callus propagation, the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

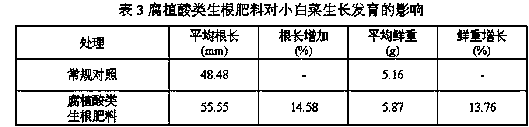

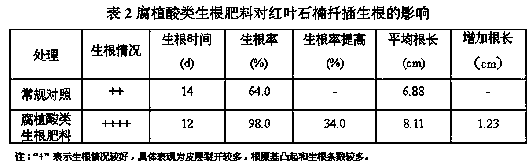

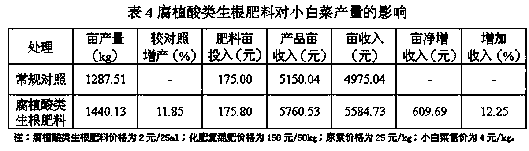

Examples

Embodiment 1

[0023] Mix 70~80kg of potassium humate containing 55~65% of humic acid with 700~750kg of demineralized water, keep the temperature at 50~55°C for 1 hour, then add 180~200kg of potassium nitrate, 80~120kg of hydrogen phosphate Diammonium, 0.4~0.55kg potassium naphthalene acetate, 0.8~1.5kg potassium indolebutyrate, 5~15kg dimethyl sulfoxide and 1~5kg polyvinyl alcohol, react at 55°C for 1.5 hours, cool to 40°C, add 5~15g potassium iodide, continue to stir and emulsify under the action of the emulsification pump in the finished product preparation tank for 3~4 hours, then return to room temperature, dark brown color, moderate viscosity, pH 8.2, humic acid concentration up to 42g / L, N+P 2 o 5 +K 2 O≥230g / L humic acid rooting fertilizer.

Embodiment 2

[0025] Mix 75~85kg of sodium humate containing 50~60% of humic acid with 650~700kg of demineralized water, keep the temperature at 55°C for 0.5 hours, then add 150~200kg of potassium nitrate, 150~200kg of diammonium hydrogen phosphate , 0.3~0.45kg potassium naphthalene acetate, 0.55~1.3kg potassium indolebutyrate, 10~15kg dimethyl sulfoxide and 3~8kg polyvinyl alcohol, react at 55°C for 1 hour, cool to 35°C, add 10~ 20g of potassium iodide, continue to stir and emulsify for 3~4 hours under the action of the emulsification pump in the finished product preparation tank, and then return to room temperature to obtain dark brown, moderate viscosity, pH at 8.4, humic acid concentration of 45g / L, N+P 2 o 5 +K 2 O≥240g / L humic acid rooting fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com