Structurally heat-preserving integrated pressure-bearing template and building construction method applying same

A technology for structural heat preservation and pressing templates, which is applied in chemical instruments and methods, buildings, building components, etc. It can solve the problems of no force bearing, affecting the service life of the board, peeling, etc., and achieves the suppression of separation and pressure bearing capacity between different layers The effect of improving and improving the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

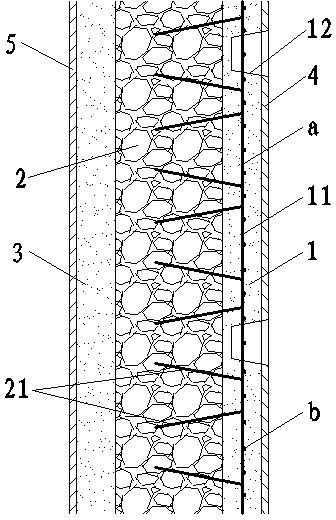

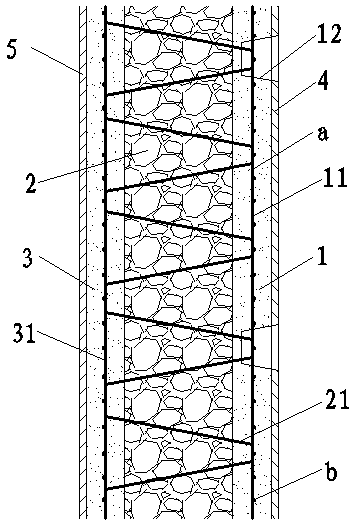

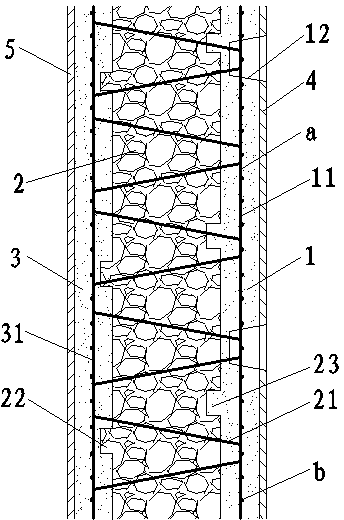

[0025] The invention discloses a structural heat preservation integrated pressure-bearing formwork, see figure 1 , 2 , 3, including the first bonding layer 1, the heat insulation layer 2 and the second bonding layer 3 arranged in sequence, the first steel wire mesh 11 is arranged inside the first bonding layer, and the first steel wire mesh is fixedly connected with Inserting ribs 21, the inserting ribs are inserted into the thermal insulation layer, and the first bonding layer is provided with a plurality of holes 12, each of which is formed by crossing a longitudinal steel wire a and a transverse steel wire b on the first steel wire mesh. The connecting points are exposed to the outside through the corresponding holes, and the first bonding layer is a bonding layer of vitrified microbeads, a bonding layer of rubber powder polystyrene particles, or a bonding layer of vitrified microbeads and rubber powder Polystyrene particle mixed material bonding layer, the second bonding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com