Heat pipe and steam compression compound type base station energy-saving air conditioner

A technology of compound base station and energy-saving air conditioner, applied in the field of heat pipe and vapor-compression compound base station energy-saving air conditioner, can solve the problems of poor cooling effect, high energy consumption, complex structure, etc. The effect of high cycle efficiency and compact unit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

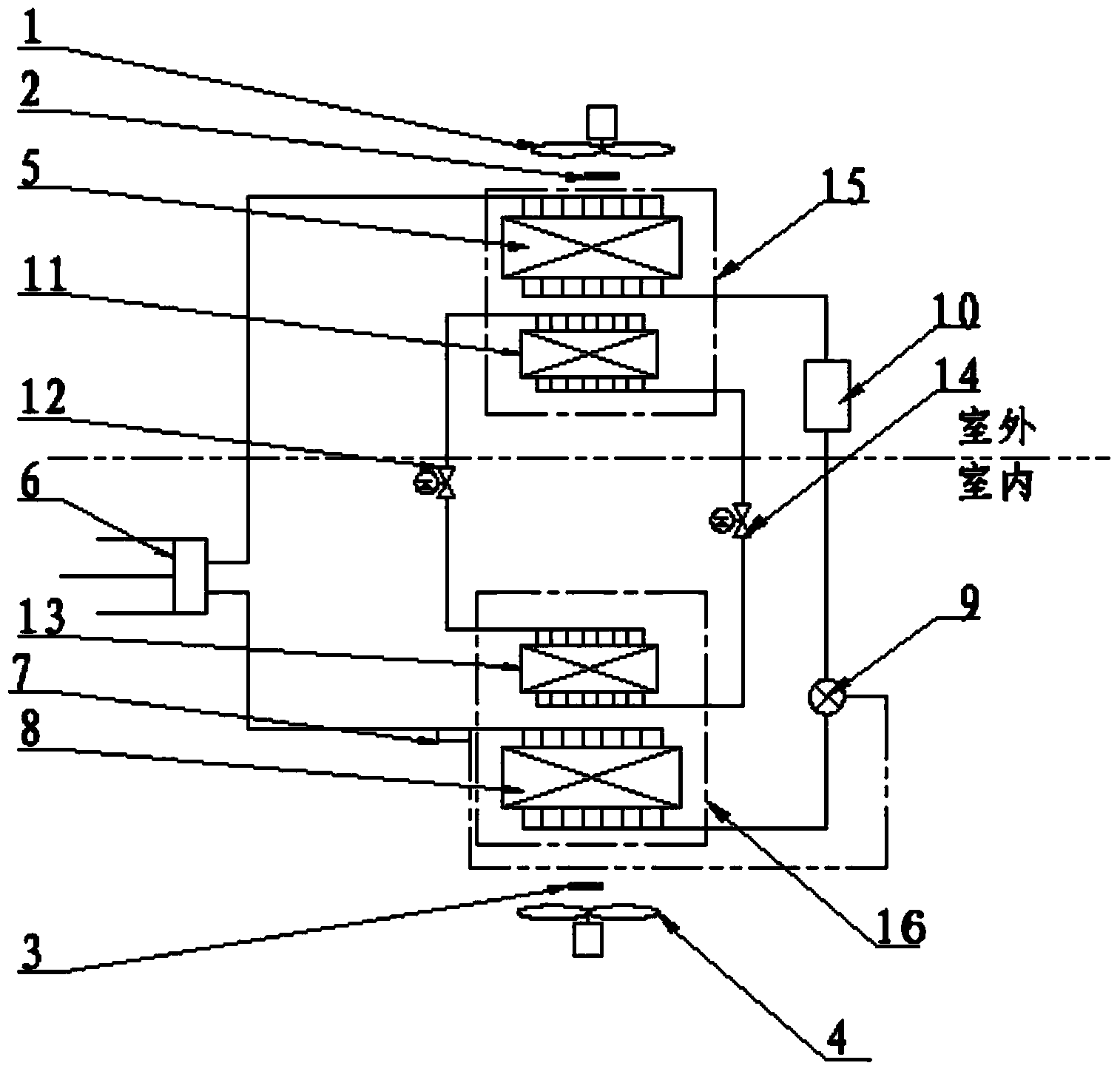

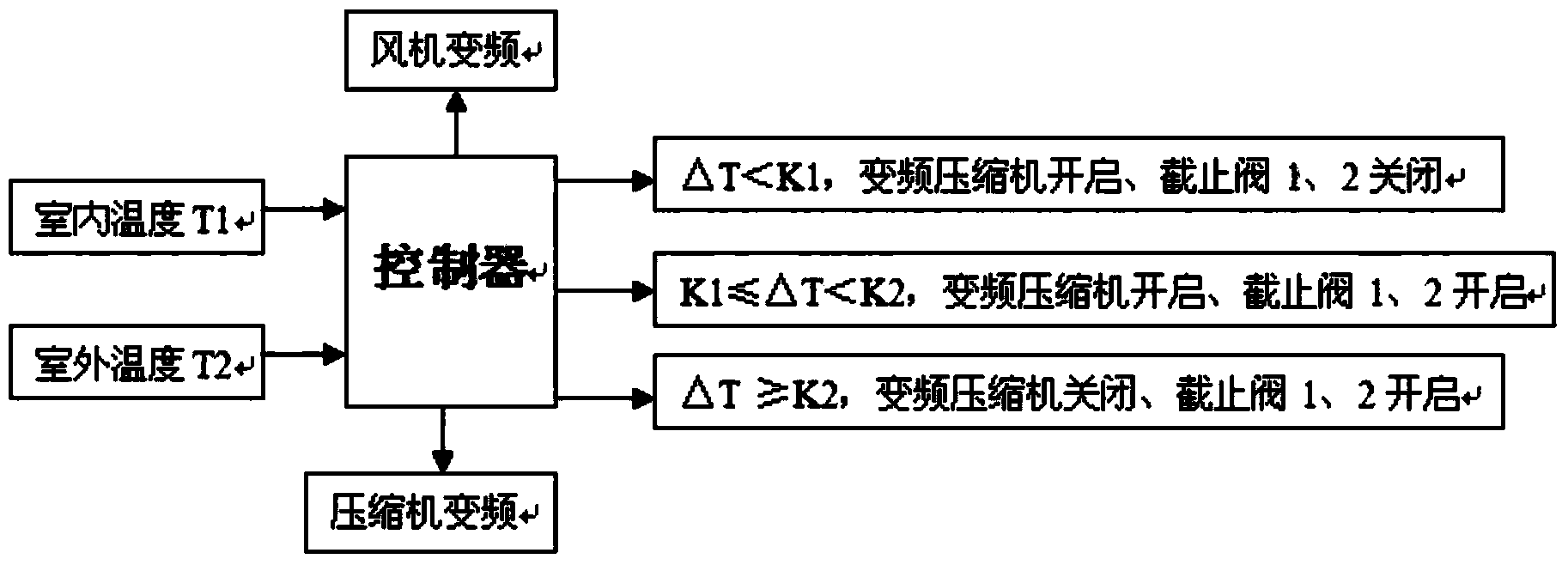

[0023] Now, the present invention will be described in further detail in conjunction with the accompanying drawings and specific embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

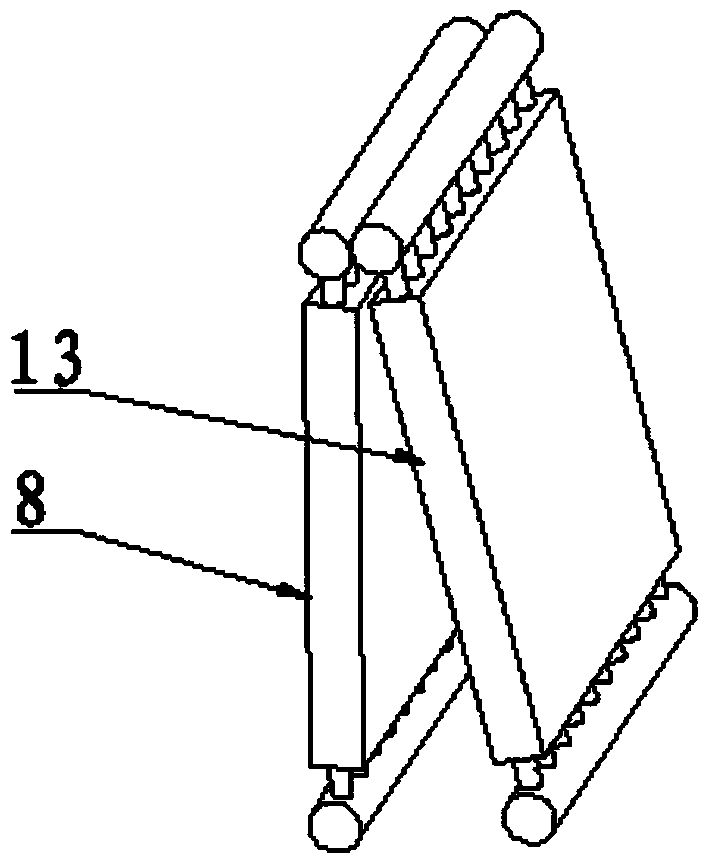

[0024] like figure 1 As shown, a heat pipe and vapor compression composite base station energy-saving air conditioner has: a heat pipe system, including a heat pipe condenser 11, an electric stop valve 12, a heat pipe evaporator 13, and an electric stop valve 2 14, which are sequentially connected through pipes to form a circuit;

[0025] The vapor frequency conversion compression refrigeration cycle system includes a condenser 5, a frequency conversion compressor 6, an evaporator 8, a thermal expansion valve 9, and a liquid storage tank 10, which are sequentially connected through pipelines to form a circuit. The thermal ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com