Simple handheld wire winding machine and use method thereof

A winding machine and winding technology, applied in the field of machinery, can solve the problems of high labor intensity and low production efficiency, and achieve the effects of compact mechanical structure, improved efficiency and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

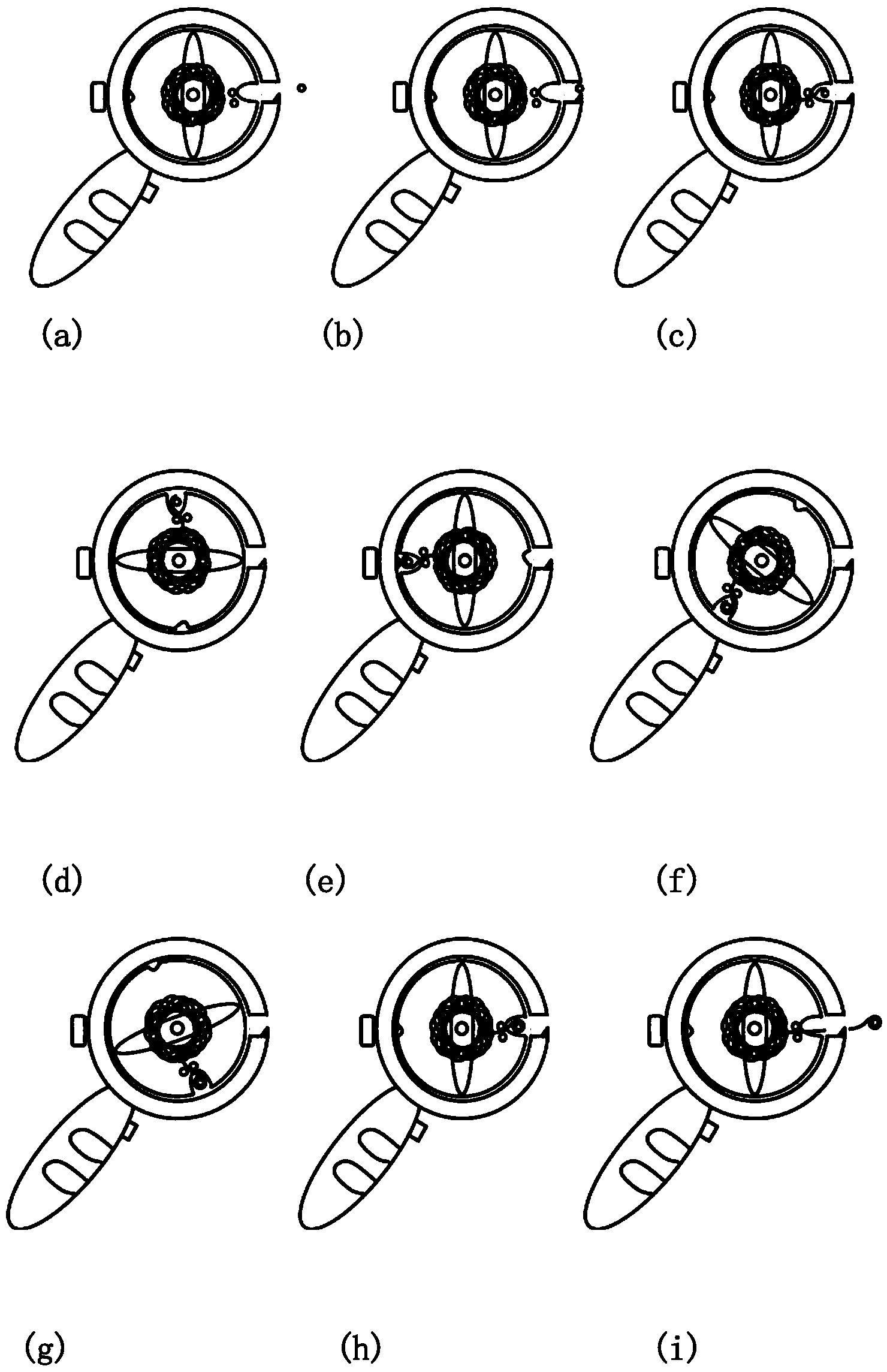

[0027] The present invention will be further described below in conjunction with accompanying drawing.

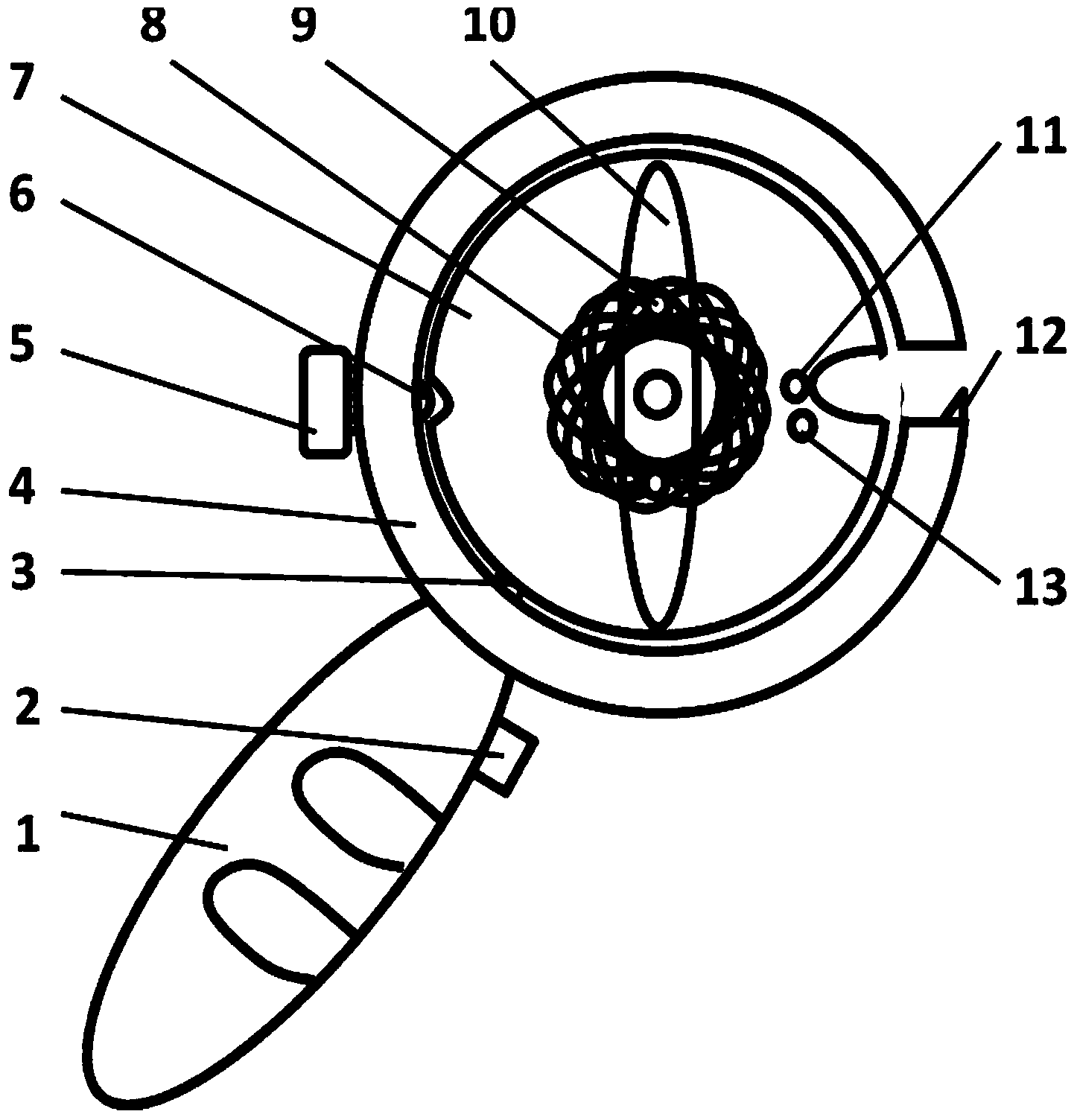

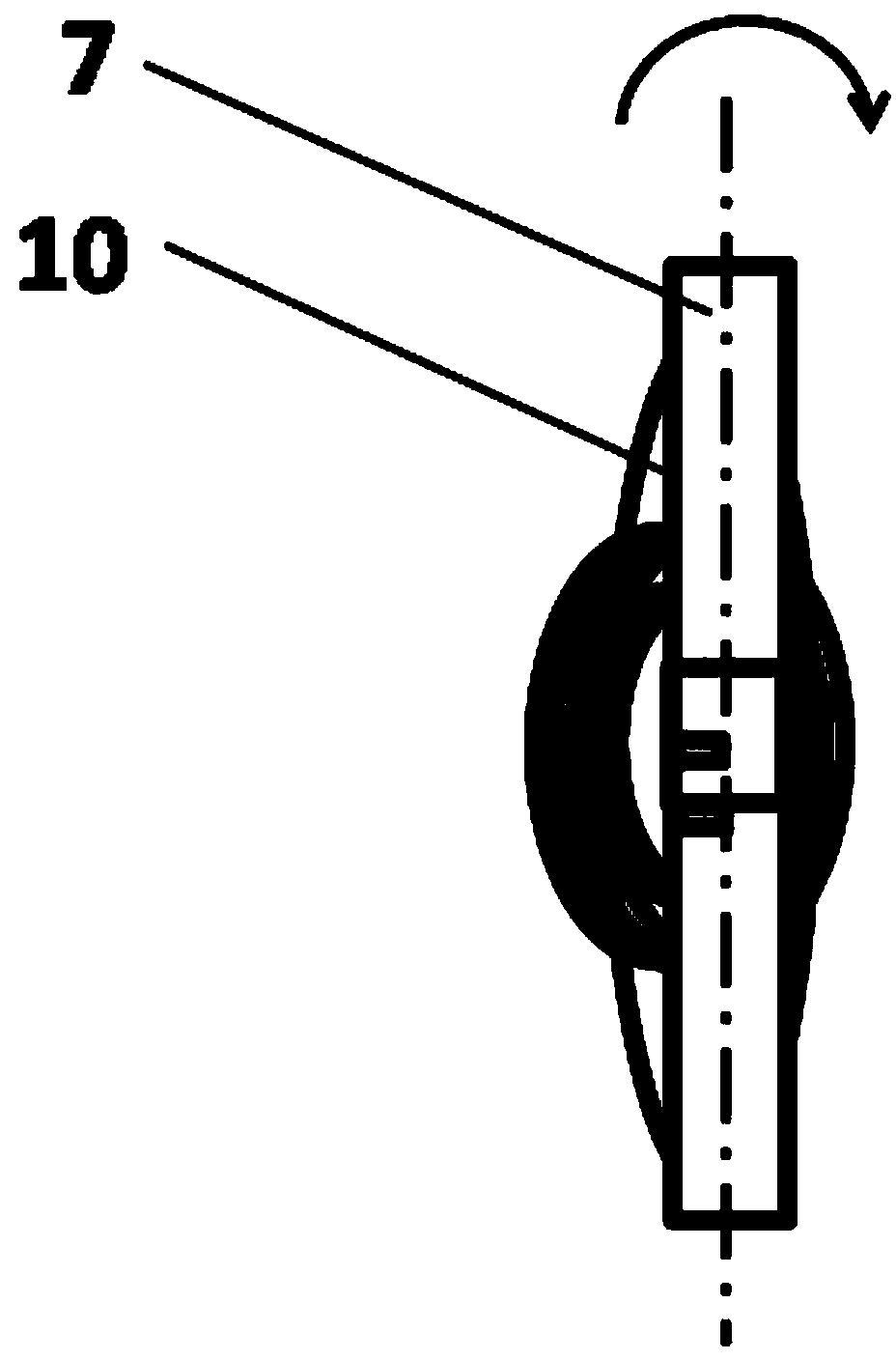

[0028] Such as figure 1 , figure 2 As shown, a simple hand-held winding machine includes a handle 1, a brake button 2, a brake pad 3, a bushing 4, a counter 5, a reset device 6, a turntable 7, a coil 8, a staple 9, an adjustable angle Card seat 10, upper limit block 11, notch 12, lower limit block 13.

[0029] The brake button 2 is arranged on one side of the handle 1, and the top of the handle 1 is fixedly connected with the shaft sleeve 4 by screws. The brake pad 3 is arranged at the top inside the handle 1, and is linked with the brake button 2,

[0030] One end of the counter 5 is arranged on the outer peripheral surface of the shaft sleeve 4, specifically on the outer peripheral surface of the shaft sleeve 4 on the left or right side above the handle; the reset device 6 is arranged on the inner side of the shaft sleeve 4, corresponding to the position of the counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com