A cleaning method for a silicon-based substrate diffuser

A diffusion sheet and substrate technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem that the bonding surface is not easy to clean, so as to save cleaning costs and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

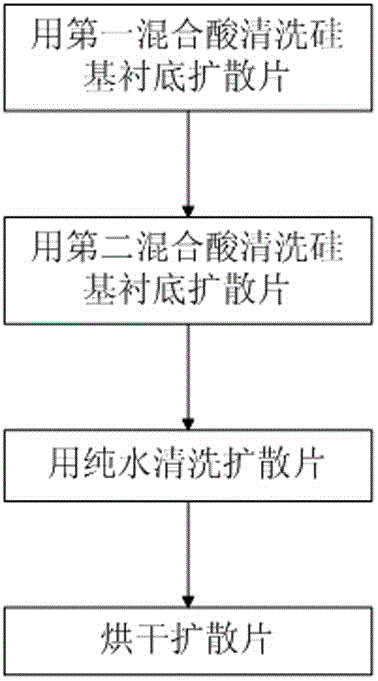

[0034] A method for cleaning a silicon-based substrate diffuser, comprising the steps of:

[0035] The first step is to soak the silicon-based substrate diffusion sheet to be cleaned in HF and HNO 3 In the mixed first mixed solution, the duration is about 30 minutes, and the volume mixing ratio of the two acids in the first mixed solution is HF:HNO 3 =20:1; The purpose of this step is to subject the diffusion sheet to strong corrosion, remove the blue film and diffusion layer on the surface of the diffusion sheet to the greatest extent, and prolong the reaction time to make the reaction more complete.

[0036] The second step is to take out the soaked diffuser and then soak it in HF+HNO 3 In the mixed second mixed solution, the duration is 5 minutes, and the volume mixing ratio of the two acids in the second mixed solution is 1:20; the purpose of this step is to remove the oxidation caused by the soaking of the first mixed acid on the surface of the diffusion sheet, At the s...

Embodiment 2

[0044] A method for cleaning a silicon-based substrate diffuser, comprising the steps of:

[0045] The first step is to soak the silicon-based substrate diffusion sheet to be cleaned in HF+HNO 3 In the mixed first mixed solution, the duration is about 35 minutes, and the volume mixing ratio of the two acids in the first mixed solution is HF:HNO 3 =23:1; the acid concentration of HF is 41%, HNO 3 The acid concentration is 65%.

[0046] The second step is to take out the soaked diffuser and then soak it in the second mixture of HF+HNO3 for 8 minutes. The volume mixing ratio of the two acids in the second mixture is HF:HNO 3 =1:30; the acid concentration of HF is 40%, HNO 3 The acid concentration is 64%.

[0047] The third step is to put the diffusion sheet reacted from the second step into pure water with a conductivity of 15 trillion for overflow rinsing, and add compressed air for bubbling to facilitate the rinsing of the acid solution remaining in the sheet. The pH of pu...

Embodiment 3

[0050] A method for cleaning a silicon-based substrate diffuser, comprising the steps of:

[0051] The first step is to soak the silicon-based substrate diffusion sheet to be cleaned in HF+HNO 3 In the mixed first mixed solution, the duration is about 45 minutes, and the volume mixing ratio of the two acids in the first mixed solution is HF:HNO 3 =20:1; the acid concentration of HF is 39%, HNO 3 The acid concentration is 69%.

[0052] The second step is to take out the soaked diffuser and then soak it in the second mixture of HF+HNO3 for 10 minutes. The volume mixing ratio of the two acids in the second mixture is HF:HNO 3=1:30; the acid concentration of HF is 42%, HNO 3 The acid concentration is 62%.

[0053] The third step is to put the diffusion sheet reacted from the second step into pure water with a conductivity of 16 trillion for overflow rinsing, and add compressed air for bubbling to facilitate the rinsing of the acid solution remaining in the sheet. The pH of pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com